Machining device and method for controlling size of tungsten molybdenum wire

A technology of processing equipment and size, which is applied in the field of tungsten and molybdenum wire preparation, can solve problems such as irremediable, unsatisfactory, and must be re-cleaned, and achieve the effects of reducing the first-time unqualified rate, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

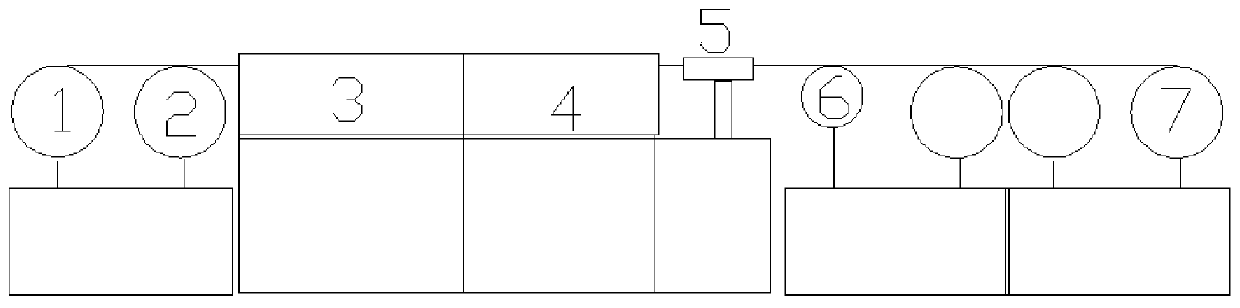

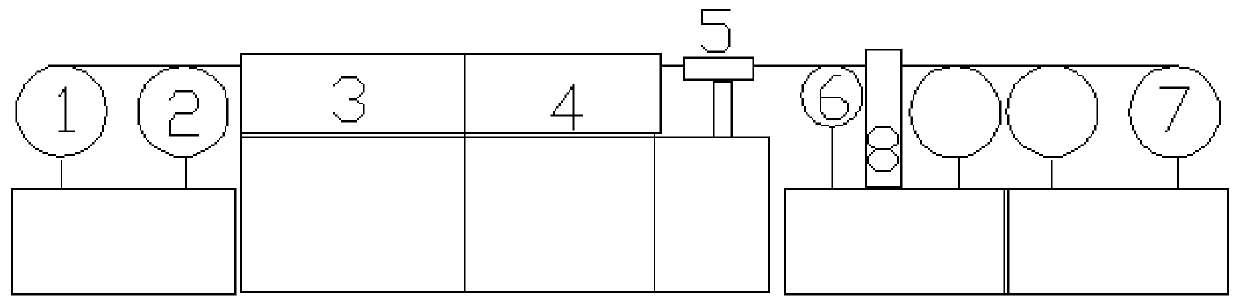

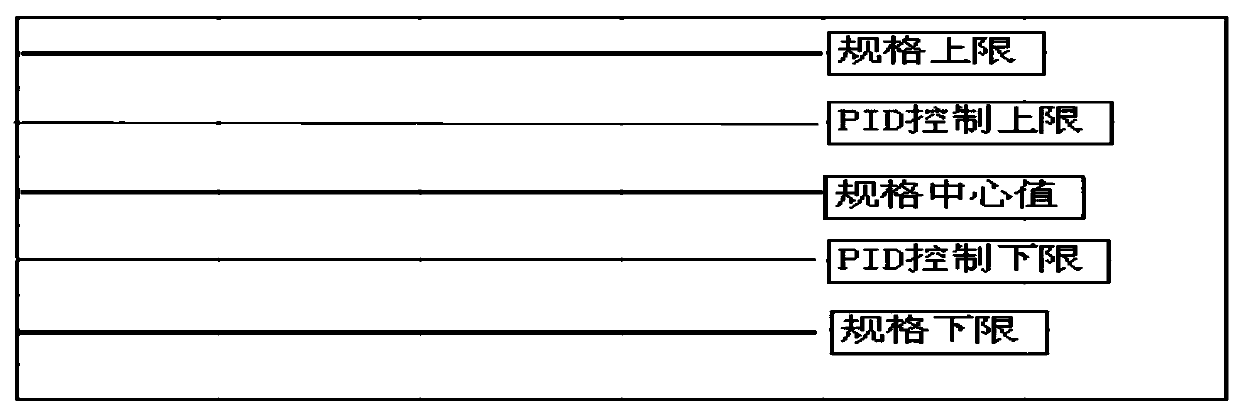

[0029] Such as figure 2 As shown, the tungsten wire cleaning device of the present invention (control components are not shown) comprises pay-off wheel 1, tension regulator 2, electrolytic tank 3, cleaning tank 4, drying box 5, wire wheel 6, laser diameter gauge, Take-up wheel 7; also includes PID controller, current tester; the input end of current tester is connected between electrolysis electrode cathode and electrolysis power supply, and output end is electrically connected to the input end of controller; Connect the input end of the controller; the output end of the PID controller is connected to the current regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com