A rotary drum reactor for pulse chemical vapor deposition coating and its application

A chemical vapor deposition and reactor technology, applied in the field of reactors, can solve the problems of slow reaction, uneven thickness, and accelerated gas phase coating reaction rate, etc., and achieve the effects of simple operation, easy processing and manufacturing, and improved gas conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

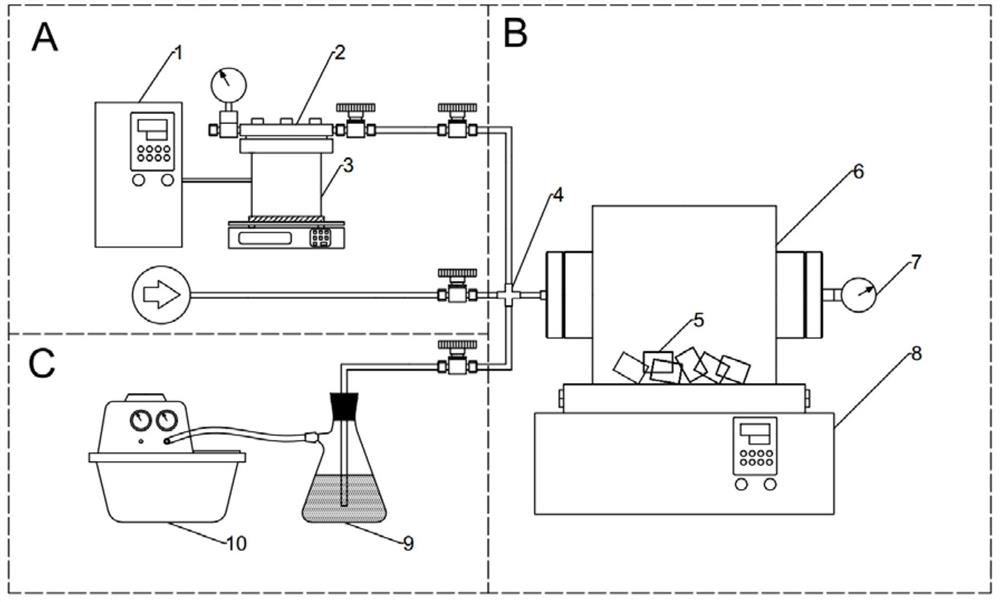

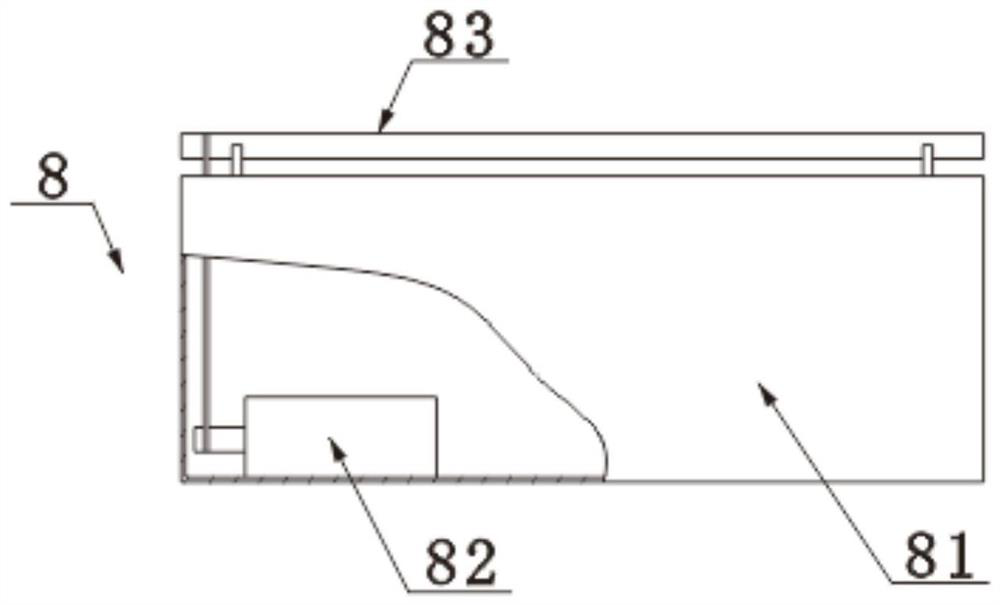

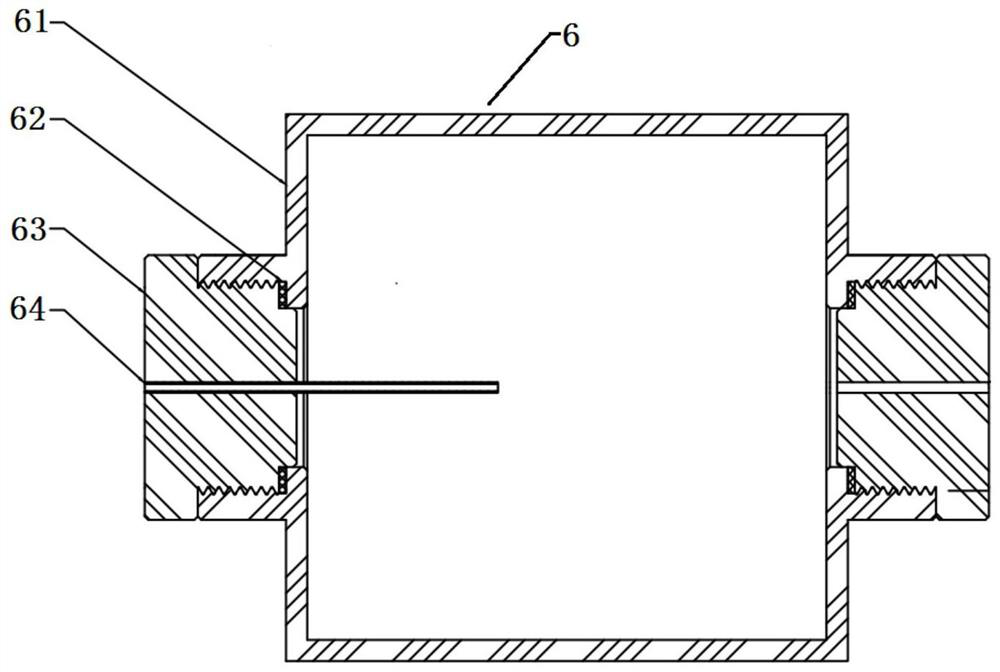

[0035] In the embodiment of the present invention, such as Figure 1~3 As shown, a rotary drum reactor for pulse chemical vapor deposition coating is provided. The rotary drum reactor in the present invention includes a precursor supply part A, a reaction part B and an exhaust gas treatment part C. Such as figure 1 As shown, the precursor supply part A includes the supply of SiCl 4 The first air supply part and the second air supply part supply water vapor; wherein, the second air supply part is a pipe with two ends open, which is used to fill the reaction drum 6 with air with moisture; the first air supply part The gas part includes a source bottle 2, the source bottle 2 is made of stainless steel, etc., and a precursor such as SiCl is arranged inside it. 4and other cavities, the top is provided with a detachable flange cover with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com