Continuous counterweight concrete coating and curing agent online spraying equipment and method for sea pipes

A spraying equipment and a concrete spraying technology are applied in the construction equipment field of continuous sea pipe counterweight concrete spray coating and curing agent online spraying, and can solve the problems of the tightness of the film wrapping, the quality of the overlap width, and the poor working environment. , repair workload and other problems, to achieve the effect of improving automation level and construction efficiency, realizing large-scale application, and ensuring online continuity and synchronization matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

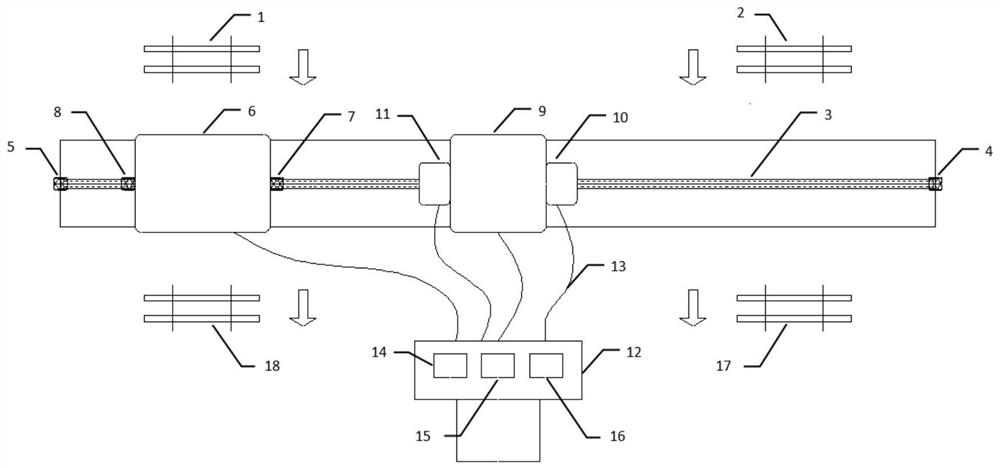

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0035] as attached figure 1 As shown, a continuous counterweight concrete coating and curing agent on-line spraying equipment for sea pipes includes a pipe inlet device, a counterweight coating track 3, a counterweight coating trolley 6, a counterweight coating process positioning device, and a counterweight Concrete spray coating system 9, curing agent spray system, industrial computer 12 and pipe outlet device.

[0036] The pipe inlet device includes 1# pipe inlet device 1 and 2# pipe inlet device 2; the pipe outlet device includes 1# pipe outlet device 17 and 2# pipe outlet device 18. The 1# pipe inlet device 1 and the 2# pipe inlet device 2 are arranged on one side of the counterweight coating track 3, and are located at both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com