Bamboo-wood fiber board using bio-based non-formaldehyde adhesive and preparation method thereof

A bamboo and wood fiber and aldehyde-free glue technology is applied in the field of fiberboard processing, which can solve the problems of poor water resistance of fiberboard, inconvenient fiberboard, low mechanical properties, etc., and achieve the effects of improving strength and water resistance, fast curing speed and high reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

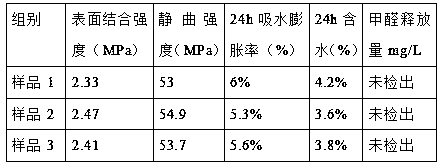

Examples

Embodiment 1

[0058] S1: Preparation of the first fiber: Take bamboo fiber and wood fiber respectively, cut them into 5 cm small pieces, mix and stir for 20 minutes, and place in air to dry to obtain the first fiber;

[0059] S2: Preparation of the second fiber:

[0060] Take anhydrous aluminum chloride, aluminum powder and water, dissolve anhydrous aluminum chloride in water, add aluminum powder after the reaction is complete, react for 2 hours, filter, add magnesium lactate to the filtrate, stir for 10 minutes, then add acetic acid, continue stirring 20min, vacuum distillation, obtain spinning solution;

[0061] Take the spinning solution, spin it in a high-speed centrifugal at a centrifugal speed of 20,000 r / min, then spray it under a high-speed hot air flow, draw and solidify, the temperature of the hot air flow is 50°C, and the speed of the hot air flow is 10m / s to obtain spun fibers;

[0062] Then place the spun fiber in an electric furnace, raise the temperature to 590°C at a rate o...

Embodiment 2

[0078]S1: Preparation of the first fiber: Take bamboo fiber and wood fiber respectively, cut them into 6 cm small pieces, mix and stir for 25 minutes, and place in air to dry to obtain the first fiber;

[0079] S2: Preparation of the second fiber:

[0080] Take anhydrous aluminum chloride, aluminum powder and water, dissolve anhydrous aluminum chloride in water, add aluminum powder after the reaction is complete, react for 2.5 hours, filter, add magnesium lactate to the filtrate, stir for 15 minutes, then add acetic acid, continue Stir for 25min, and distill under reduced pressure to obtain spinning solution;

[0081] Take the spinning solution, spin it in a high-speed centrifugal at a centrifugal speed of 25,000r / min, then blow it under a high-speed hot air flow, draw and solidify, the temperature of the hot air flow is 55°C, and the speed of the hot air flow is 30m / s to obtain spun fibers;

[0082] Then place the spun fiber in an electric furnace, raise the temperature to 5...

Embodiment 3

[0098] S1: Preparation of the first fiber: take bamboo fiber and wood fiber respectively, cut them into small pieces of 8 cm, mix and stir for 30 minutes, and place them in air to dry to obtain the first fiber;

[0099] S2: Preparation of the second fiber:

[0100] Take anhydrous aluminum chloride, aluminum powder and water, dissolve anhydrous aluminum chloride in water, add aluminum powder after the reaction is complete, react for 3 hours, filter, add magnesium lactate to the filtrate, stir for 20 minutes, then add acetic acid, continue stirring 30min, vacuum distillation, obtain spinning solution;

[0101] Take the spinning solution, spin it in a high-speed centrifugal at a centrifugal speed of 30,000 r / min, then spray it under a high-speed hot air flow, draw and solidify, the temperature of the hot air flow is 60°C, and the speed of the hot air flow is 50m / s to obtain spun fibers;

[0102] Then place the spun fiber in an electric furnace, raise the temperature to 600°C at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com