Novel sealing mask and manufacturing process thereof

A production process and mask technology, applied in the direction of sewing tools, clothing, clothing, etc., can solve problems such as bleeding ulcers, facial injuries, ear discomfort, etc., and achieve the effect of changing the production process, comprehensive protection, and simplifying production steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

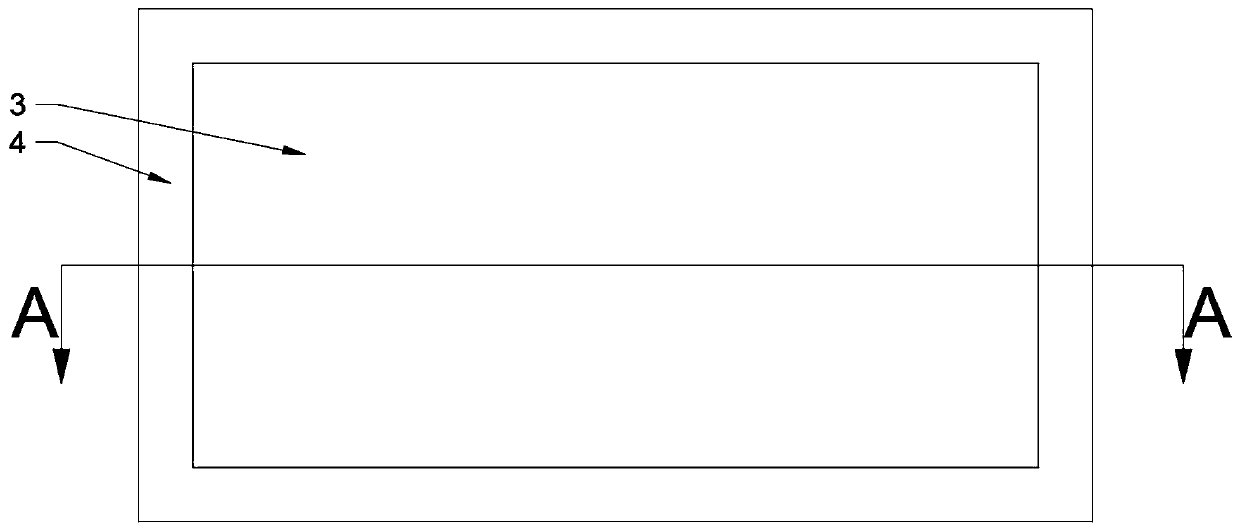

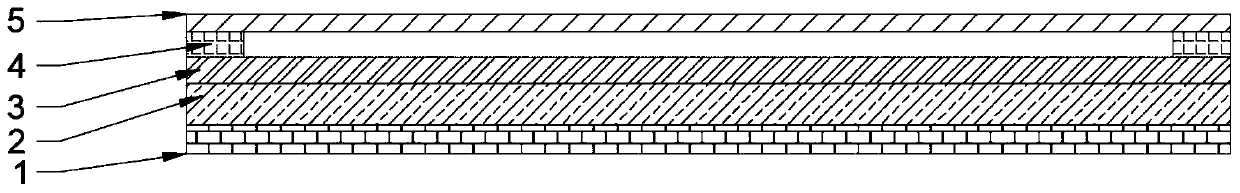

[0020] When the present invention is implemented in practice, a novel airtight mouth mask and its manufacturing process comprise an outer layer of the mouth mask 1, the outer layer of the mouth mask 1 is a hydrophobic layer, and the outer layer of the mouth mask 1 is provided with a hot-melt blown cloth layer 2, so A water-absorbing layer 3 is provided inside the thermal-sprayed fleece layer 2 , an adhesive tape 4 is provided at the edge of the water-absorbing layer 3 , and an adhesive tape protection layer 5 is provided on the outer layer of the adhesive tape 4 .

[0021] The outer layer 1 of the mask, the hot-melt blown cloth layer 2 and the water-absorbing layer 3 adopt stamping and seaming.

[0022] The outer layer 1 of the mask, the hot-melt blown cloth layer 2, the water-absorbing layer 3, the adhesive tape 4 and the protective tape layer 5 are all prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com