Structure capable of preventing concrete long wall early cracking, construction method and application

A concrete wall and concrete technology, which is applied in the direction of building components, building structures, building insulation materials, etc., can solve the problems that the load bearing capacity cannot meet the use requirements, the old and new concrete are not reliably connected, and affect the overall performance of the structure, etc., to achieve Enhance toughness, reduce cement consumption, and reduce water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

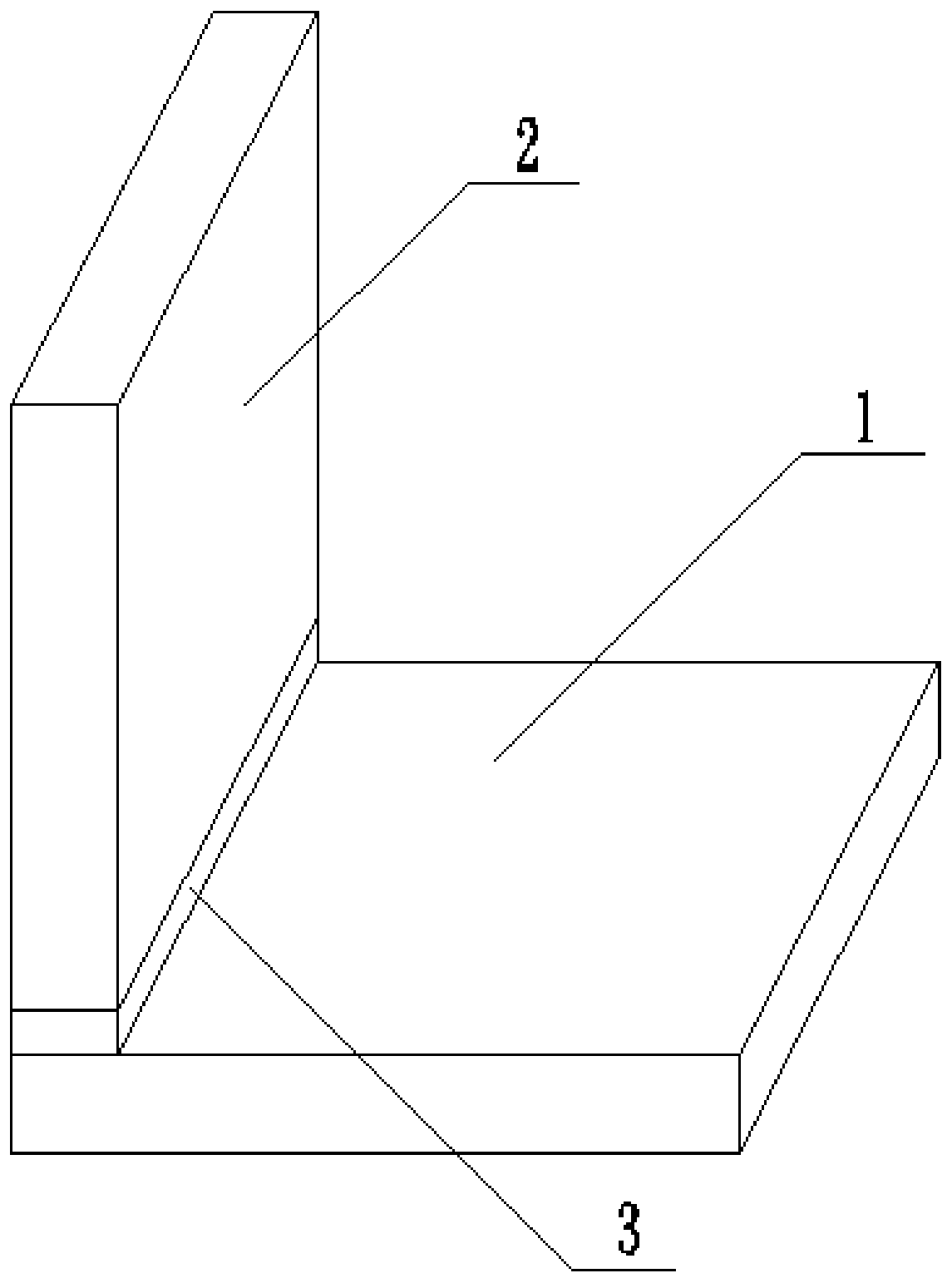

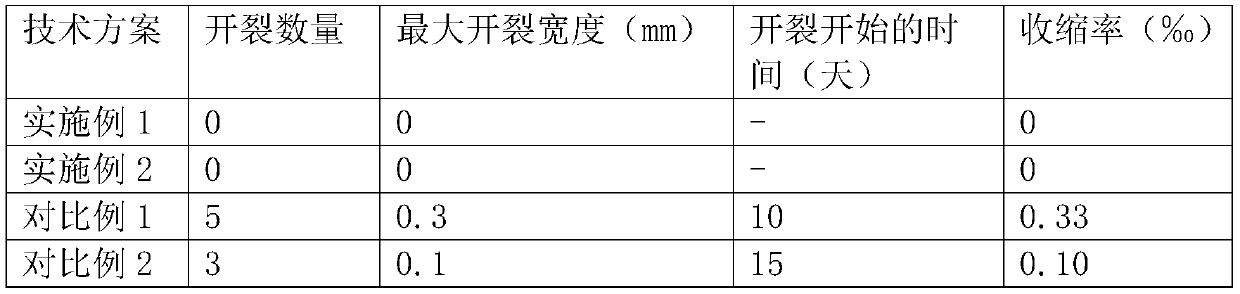

[0020] Such as figure 1 Shown, the present invention comprises existing concrete wall body 1, newly poured concrete wall body 2, and is arranged on the mortar retarding layer 3 between existing concrete wall body and newly pouring concrete wall body, the mortar retarding layer The setting time is 6 days, and the mortar retarding layer reaches the design strength within 28 days after pouring, and the shrinkage rate is 0%. The mortar retarding layer includes a retarder with a weight percentage of 0.5%, and the retarder includes the following weight components , sucrose 100g / L, citric acid 300g / L, sodium tripolyphosphate 50g / L, sodium pyrophosphate 10g / L. The thickness of the newly poured concrete wall is 50cm.

[0021] The construction method comprises the steps of pouring a 5cm mortar retarding layer on the existing concrete wall, and then pouring a newly poured concrete wall on the mortar retarding layer.

Embodiment 2

[0023] The present invention includes existing concrete walls, newly poured concrete walls, and a concrete retarding layer arranged between the existing concrete walls and newly poured concrete walls, and the setting time of the mortar retarding layer is 10 days. The concrete retarding layer reaches the design strength within 28 days after pouring, and the shrinkage rate is 0%. The concrete retarding layer includes a retarder with a percentage by weight of 0.8%, and the retarder includes the following weight components, sucrose 200g / L, Citric acid 200g / L, sodium tripolyphosphate 10g / L, sodium pyrophosphate 50g / L. The thickness of the newly poured concrete wall is 1m.

[0024] The construction method comprises the steps of pouring an 8cm concrete retarding layer on the existing concrete wall, and then pouring a newly poured concrete wall on the concrete retarding layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com