Production process of heat gathering material and energy gathering warmer based on heat gathering material

A production process and energy gathering technology, applied in the field of indoor heating, can solve the problem of high power consumption of electric heaters, and achieve the effects of good heat storage capacity, reduced load and low power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A production process of a heat-gathering material. The components of the heat-gathering material include: 25% to 27.5% of salt containing crystal water, 17% to 19% of stearic acid, and 8% to 10.5% of paraffin , 5% to 7% graphene, and 40% to 45% carbohydrates; the preparation process includes the following steps:

[0022] A. Grind the salt containing crystal water in the above ratio into 8-mesh uniform powder, mix it with the carbohydrate in the above ratio, heat it to 200°C-260°C, and then cool it down to 20°C-23°C through the condenser;

[0023] B. Grinding the paraffin wax in the above ratio into a 10-mesh uniform powder, mixing it with the graphene in the above ratio and the mixture obtained in step A, heating to 122°C to 125°C, and cooling to 18°C to 23°C through a condenser;

[0024] C. Mix the mixture obtained in step B with the stearic acid in the above ratio and heat it to 106°C to 108.5°C, then cool it down to 0°C through a condenser, and store ...

Embodiment 2

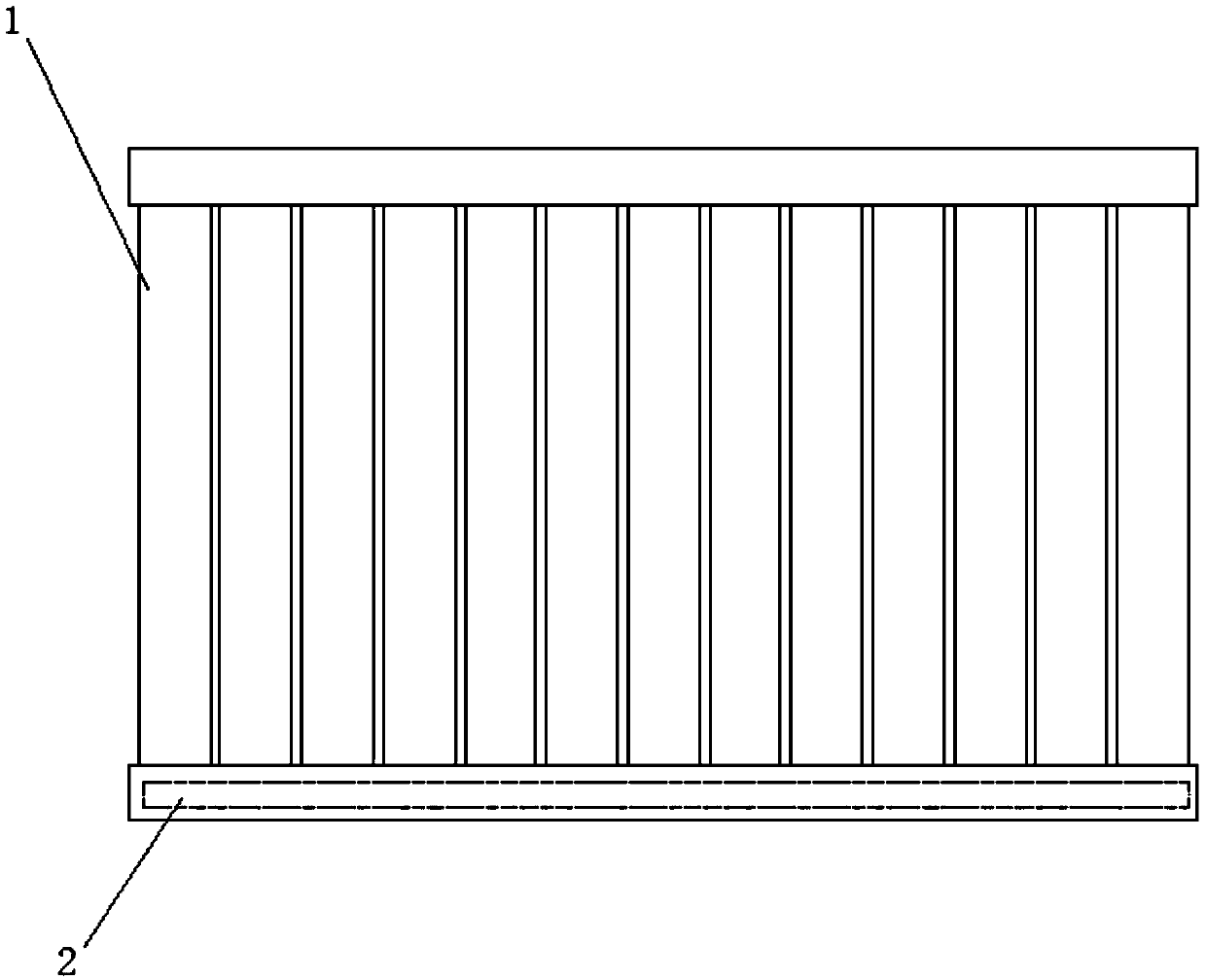

[0026] Embodiment 2: see attached figure 1 , an energy-concentrating heater based on a heat-collecting material, which includes: a heating body 1 and a heating element 2, and the heating body 1 is injected with a heat-collecting material;

[0027] The heating element 2 is installed on the inner bottom side of the heating body 1, and is used for energy triggering of the heat-gathering material.

[0028] Specifically, the heating element 2 can be an electric heating pipe or a hot water pipe.

[0029] See attached figure 2 , when the electric heating tube is used as the energy heating element, the heating power of the electric heating tube is 100W to 500W; a control panel 3 for controlling the electric heating tube is also provided on one side of the heating body 1; the control panel 3 is provided with: a switch 31 and The power adjustment knob 32 and the safety device are arranged in the control panel 3; the switch 31, the power adjustment knob 32 and the safety device are co...

Embodiment 3

[0032] Embodiment 3: Taking the energy-concentrating heater using the electric heating tube as the energy heating element as an example, the production process of the energy-concentrating heater is as follows:

[0033] A. Prepare the cooling column of the heating body 1;

[0034] The number of cooling columns can be combined freely, and the number is generally between 6-15 columns. In this example, 13 cooling columns are selected, and the material of the cooling columns is carbon steel 2570;

[0035] B. Prepare the profiles of the upper part and the bottom of the heating main body 1;

[0036] C. Weld the upper and lower profiles of the heating body 1 and the cooling column;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com