Electric heating movable floor and heating system consisting of electric heating movable floor

A raised floor and electric heating technology, applied in the field of building decoration materials, can solve problems such as difficulty in maintenance, impact of spot heating floor strength, interference of electronic equipment, etc., to reduce maintenance costs, ensure heating demand, and avoid low-temperature dead ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

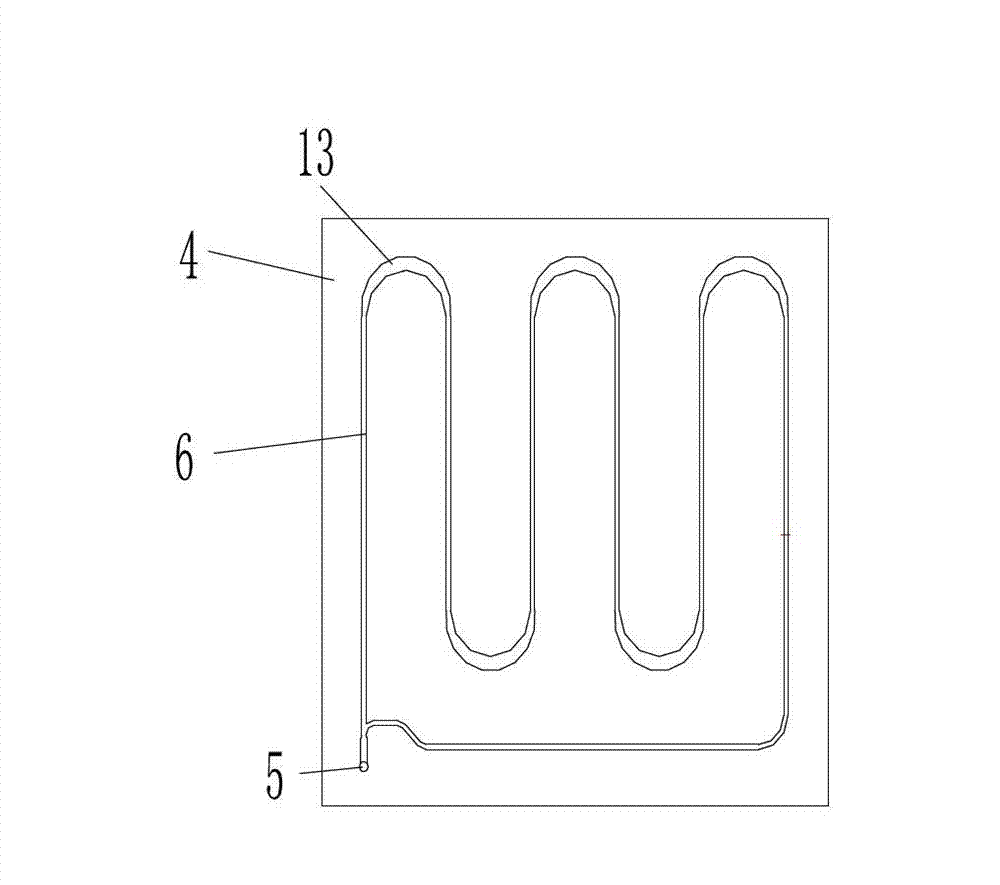

[0035] Such as figure 1The electric heating access floor shown includes a floor base 4 mainly made of calcium sulfate material, and is characterized in that: the floor base is provided with connecting through holes 5, and the upper surface of the floor base 4 is provided with There is a wiring groove 6 embedded with a heating wire, the starting point and the end point of the wiring groove 6 communicate with the connection through hole 5, and a power connector 12 is arranged in the connection through hole 5, and the two ends of the heating wire 2 are connected to the connecting hole 5. The power connector 12 is connected, and the upper surface of the floor substrate 4 is attached with a panel 1; the panel has sufficient supporting force, and the panel is directly in contact with the floor substrate to avoid direct force on the heating wire, and there is no problem of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com