Preparation method of biological basic characteristic type flame-retardant epoxy resin

An epoxy resin and biological technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of non-renewable, poor flame-retardant performance, toxic raw materials, etc., and achieve the effect of large quantity, low price and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

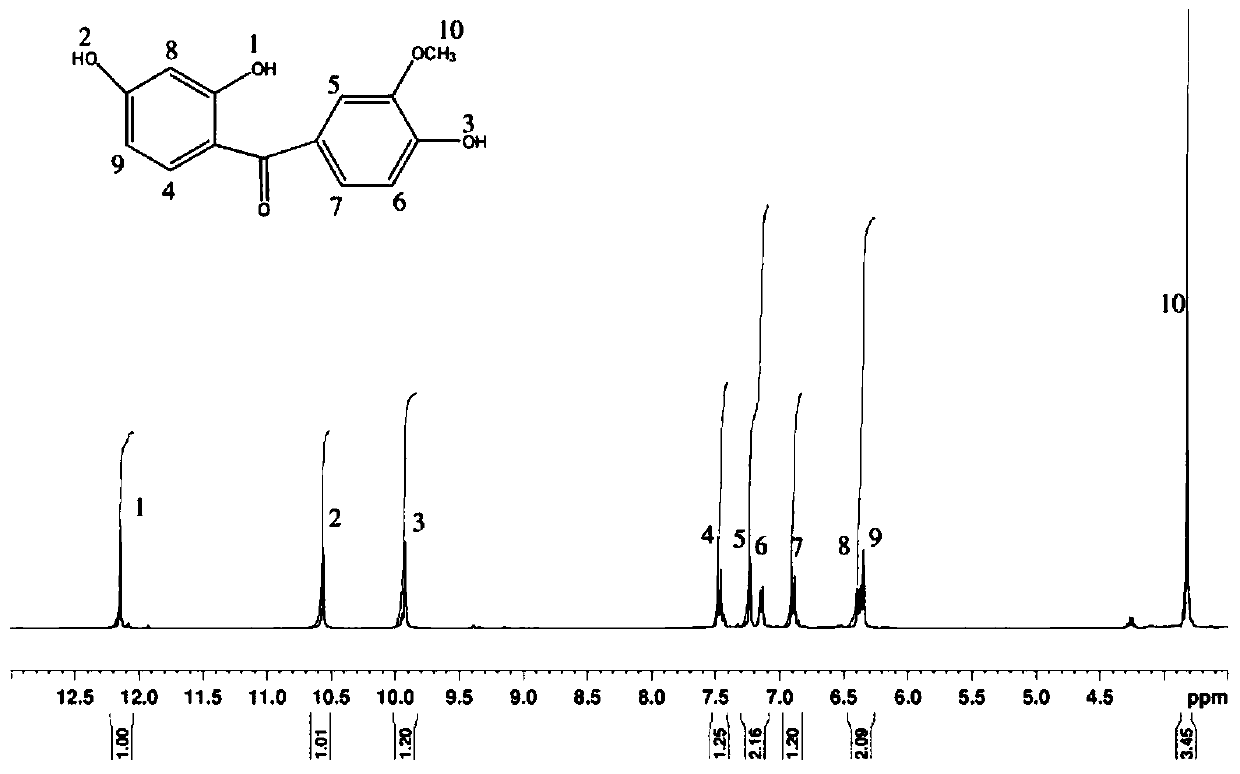

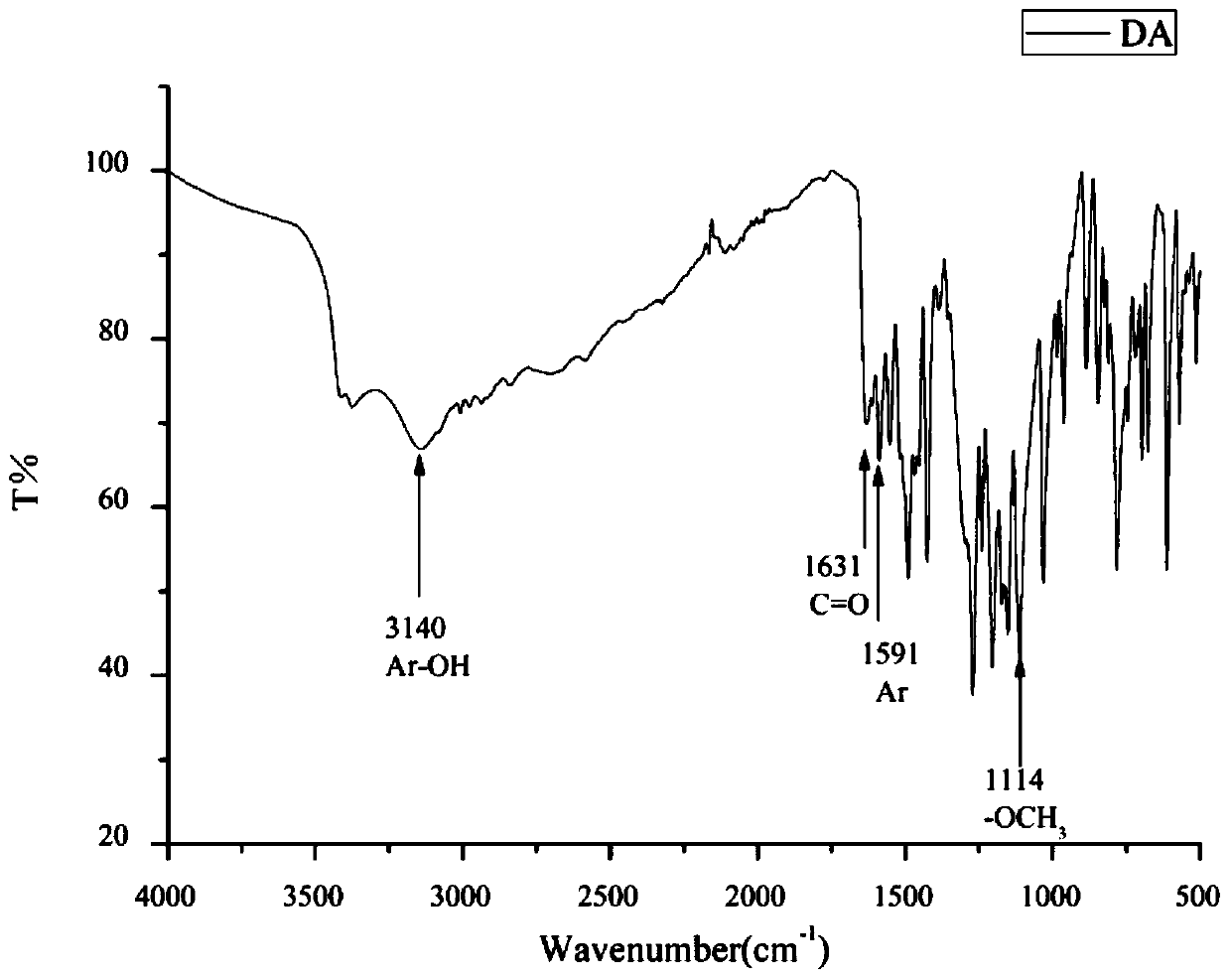

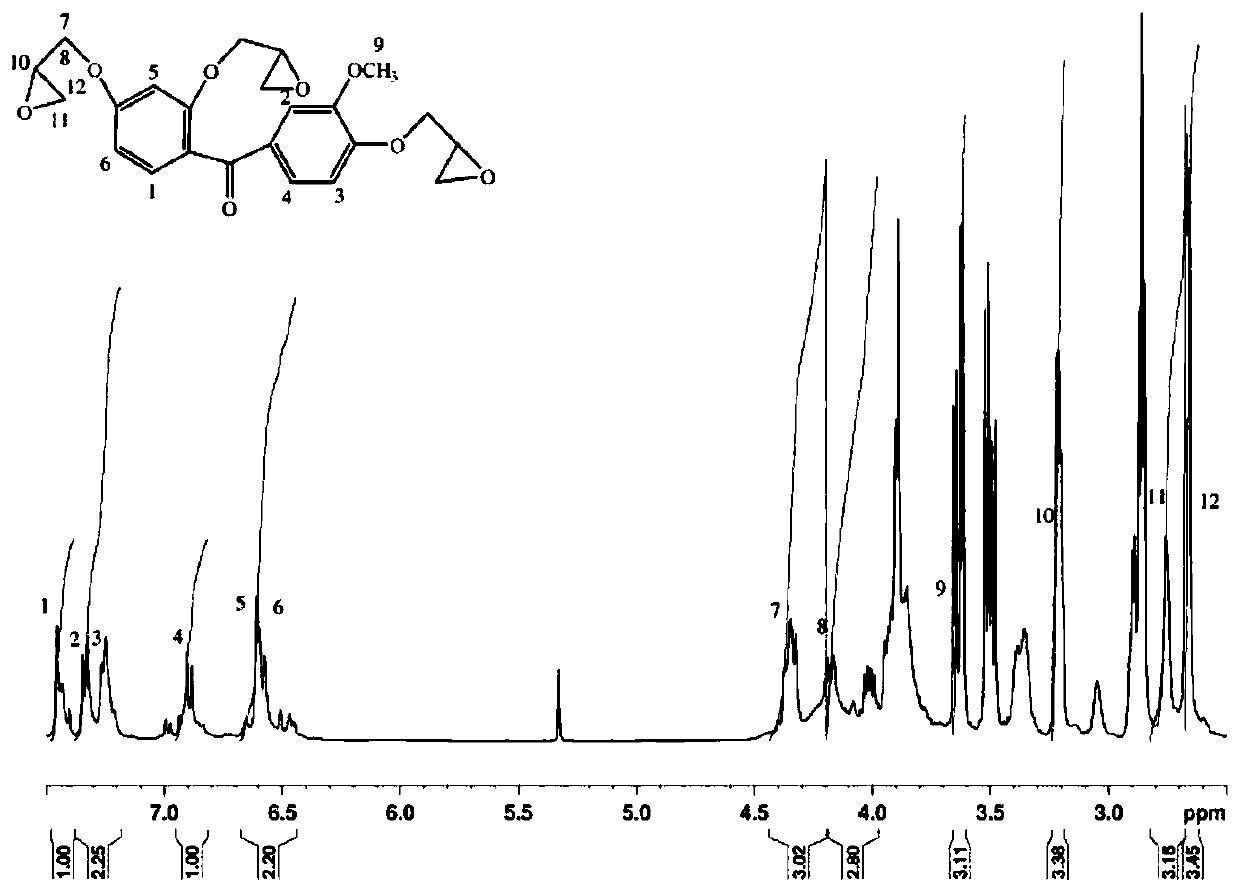

[0033] A kind of preparation method of bio-basic flame-retardant epoxy resin, vanillic acid and resorcinol undergo Friedel-Crafts acylation reaction under catalytic conditions, and then undergo substitution reaction with epichlorohydrin to obtain epoxy monomer, and The curing agent DDS is mixed and cured under heating to obtain the final resin sample.

[0034] The synthesis steps of the bio-based epoxy monomer and curing agent are as follows:

[0035](1) Add a certain amount of vanillic acid, resorcinol and boron trifluoride ether into a round bottom flask with a condenser, heat to 70-120°C, and keep the mixture at this temperature for 40-120min. After cooling to room temperature, pour sodium acetate buffer solution and let it stand for 3 to 7 hours. The product was obtained by filtration, washed with water, purified by recrystallization, and then vacuum-dried at 50-80° C. for 5-9 hours to obtain the product DA. The molar ratio of vanillic acid and resorcinol is 0.7-1.5:1, t...

Embodiment 1

[0041] (1) Add 0.12 mol of vanillic acid, 0.17 mol of resorcinol and 0.36 mol of boron trifluoride ether into a round-bottomed flask with a condenser tube, heat to 120°C, and keep the mixture at this temperature for 120 min. After cooling to room temperature, pour a sodium acetate buffer solution with a mass fraction of 5%, wherein the sodium acetate is 2.4 mol, and let stand for 7 hours. The product was obtained by filtration, washed with water, purified by recrystallization from dichloromethane, and then vacuum-dried at 80° C. for 9 h to obtain the product DA.

[0042] (2) Add 0.08mol of the above-mentioned product in a round bottom flask with a condenser tube, place it under N 2 in environment. Add 0.24mol epichlorohydrin into the flask at room temperature, heat to 130°C, slowly add 10% NaOH solution within 90min, wherein the NaOH content is 0.24mol, and keep the reaction mixture at this temperature for 90min. After cooling to room temperature, the product was obtained by...

Embodiment 2

[0045] (1) Add 0.12 mol of vanillic acid, 0.17 mol of resorcinol and 0.36 mol of boron trifluoride diethyl ether into a round-bottomed flask with a condenser tube, heat to 70°C, and keep the mixture at this temperature for 40 minutes. After cooling to room temperature, pour a sodium acetate buffer solution with a mass fraction of 5%, wherein the sodium acetate is 2.4 mol, and let it stand for 3 hours. The product was obtained by filtration, washed with water, purified by tetrahydrofuran recrystallization, and then vacuum-dried at 50° C. for 5 h to obtain the product DA.

[0046] (2) Add 0.08mol of the above-mentioned product in a round bottom flask with a condenser tube, place it under N 2 in environment. Add 0.24mol epichlorohydrin into the flask at room temperature, heat to 70°C, slowly add 10% NaOH solution within 30min, wherein the NaOH content is 0.24mol, and keep the reaction mixture at this temperature for 30min. After cooling to room temperature, the product was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com