Modified activated carbon for adsorbing phenol as well as preparation method and application thereof

An activated carbon and modification technology, which is applied in the field of modified activated carbon and its preparation, can solve the problems of activated carbon micropore structure blockage, high strength, high temperature environment, etc., and achieve the effect of reducing phenol content, increasing adsorption performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

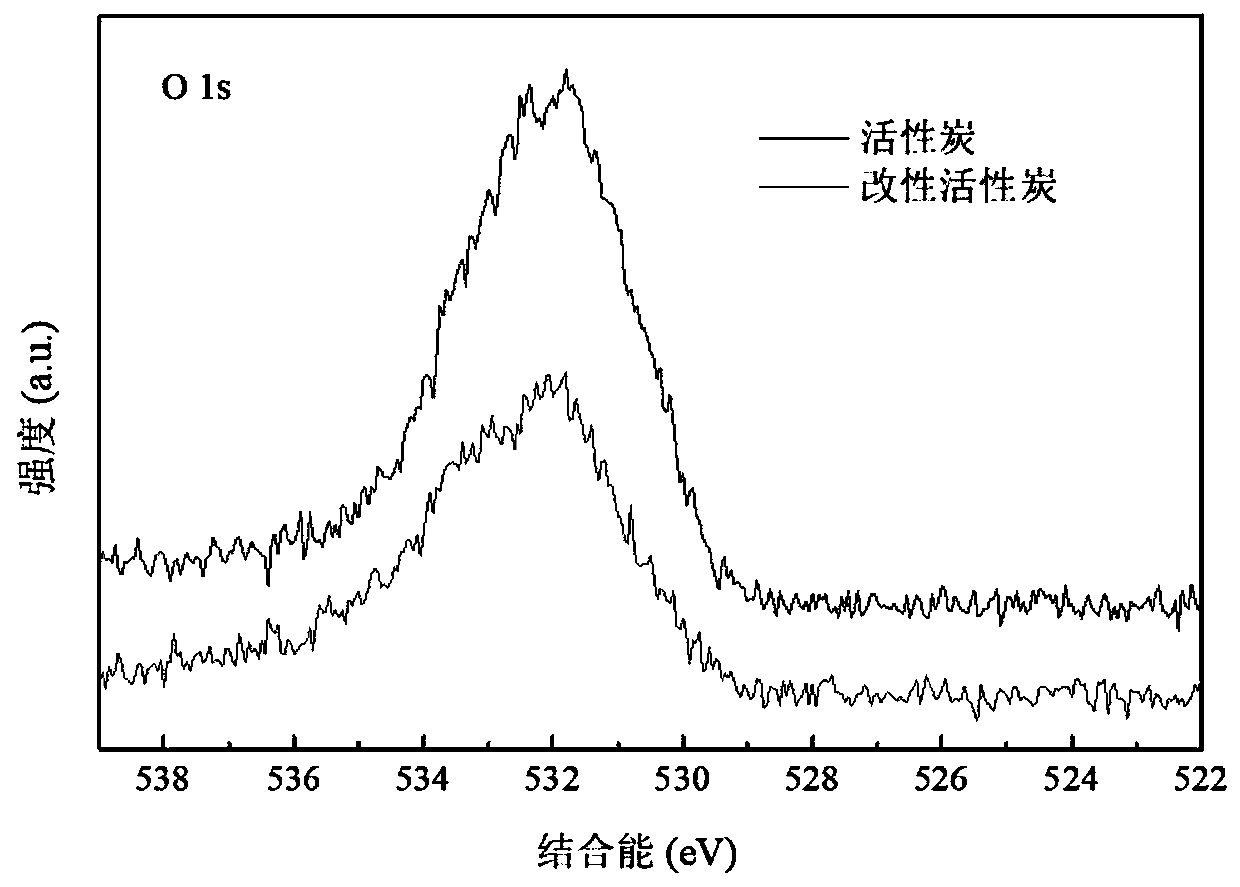

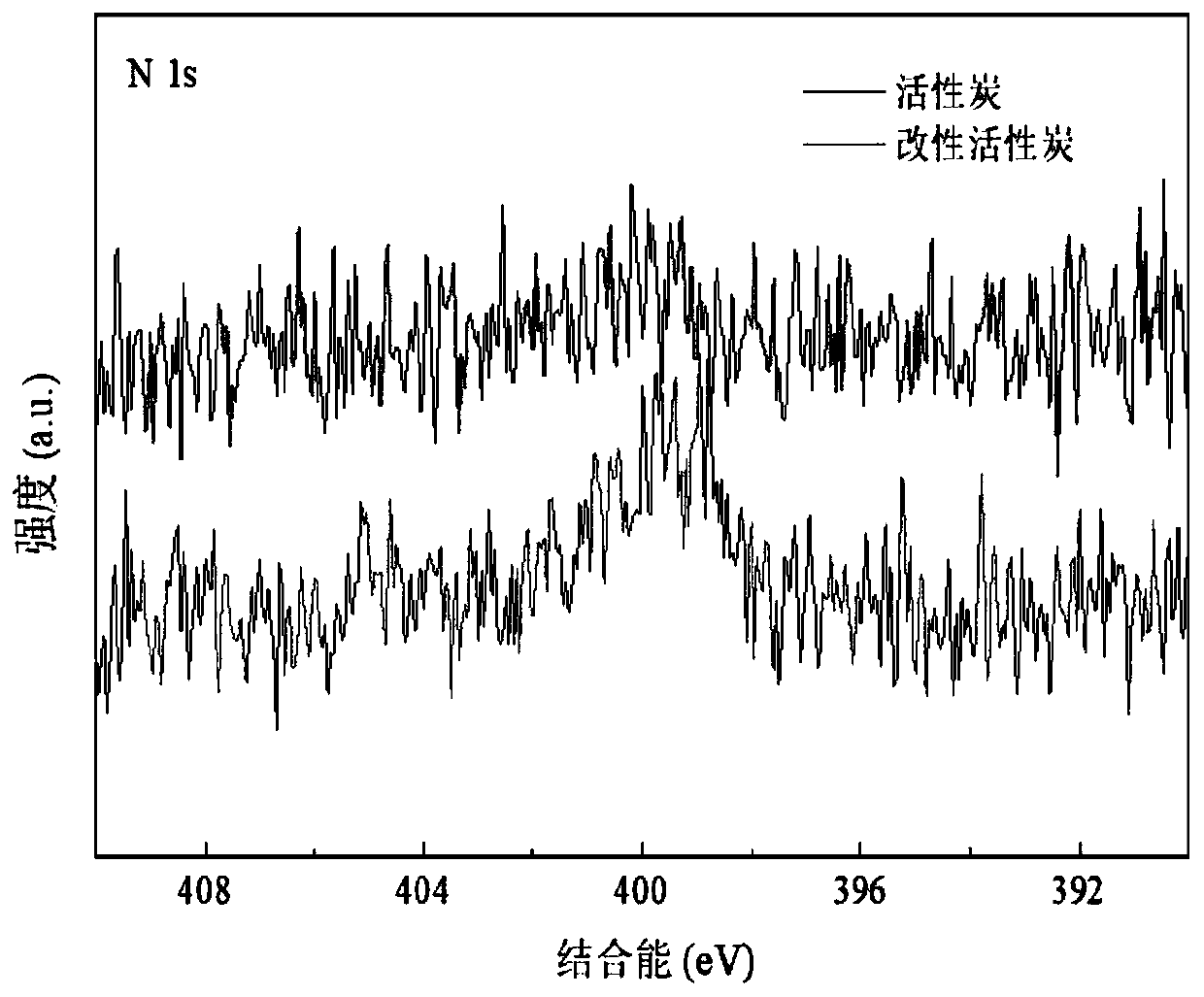

[0023] One aspect of the embodiments of the present invention provides a method for preparing a modified activated carbon that adsorbs phenol, comprising:

[0024] The activated carbon is oxidized by an oxidizing agent to obtain oxidized activated carbon;

[0025] Immersing the obtained oxidized activated carbon in an aqueous solution of nitrogen-containing small molecules to obtain activated carbon adsorbed with nitrogen-containing small molecules;

[0026] And, the obtained activated carbon adsorbed with nitrogen-containing small molecules is subjected to microwave irradiation treatment to obtain modified activated carbon adsorbed with phenol.

[0027] In some more specific embodiments, the preparation method includes: mixing activated carbon with an oxidizing agent solution, stirring and reacting at room temperature for 2-6 hours, and then washing and drying to obtain the oxidized activated carbon.

[0028] Further, the activated carbon is granular activated carbon.

[00...

Embodiment 1

[0053] A modified activated carbon is prepared and applied to a ternary composite filter stick to reduce the phenol content in mainstream smoke.

[0054] The preparation method of above-mentioned modified activated carbon is as follows:

[0055] (1) 10g particle diameter is that 40-60 purpose coconut shell activated carbon is dispersed in 100ml mass fraction and is 5% hydrogen peroxide, stirs 2h at room temperature, keeps stirring speed 400r / min, after stirring finishes, suspension is filtered, Rinse the activated carbon particles with deionized water, then place them in a drying oven, and dry them at 105°C for 4 hours to obtain oxidized coconut shell activated carbon;

[0056] (2) The oxidized coconut shell activated carbon that 1g step (1) obtains is dispersed in 100ml mass fraction and is 5% in the aqueous solution of ethylenediamine, under 30 ℃ of constant temperature conditions, magnetic force stirs 10h, keeps stirring speed 400r / min. After stirring, filter the suspensio...

Embodiment 2

[0060] A modified activated carbon is prepared and applied to a ternary composite filter stick to reduce the phenol content in mainstream smoke.

[0061] The preparation method of above-mentioned modified activated carbon is as follows:

[0062] (1) Disperse 10 g of coconut shell activated carbon with a particle size of 40-60 mesh in 100 ml of 10% hydrogen peroxide, stir at room temperature for 3 h, and keep the stirring speed at 400 r / min. After stirring, filter the suspension, wash the activated carbon particles with deionized water, then place them in a drying oven, and dry them at 105°C for 4 hours to obtain oxidized coconut shell activated carbon;

[0063] (2) the oxidized coconut shell activated carbon that 1g step (1) obtains is dispersed in 100ml mass fraction and is 10% in the ethylenedienetriamine aqueous solution, under 30 ℃ of constant temperature conditions, magnetic force stirs 10h, keeps stirring speed 400r / min, stirs After the end, filter the suspension, rinse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com