Soldering method of tantalum target material and copper back plate

A brazing method and tantalum target technology are applied in the field of welding tantalum targets and copper backplanes, which can solve the problem that the bonding strength of the welding surface needs to be further improved, and achieve long-term stable use, reliable bonding, and improved welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

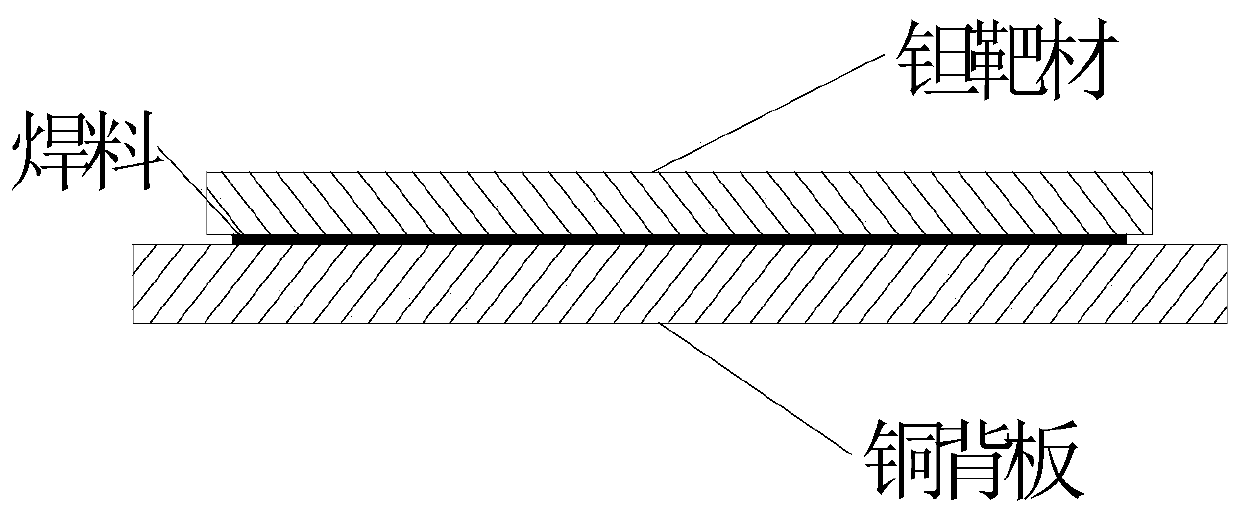

[0059] This embodiment provides a brazing method for a tantalum target and a copper back plate, the brazing method includes the following steps:

[0060] (1) Correct the warpage of the tantalum target so that the flatness of the target is ≤0.2mm;

[0061] (2) The surface of the welding surface of the tantalum target and the copper back plate is independently sandblasted; the sand used for the sandblasting is No. 46 white jade, and the air pressure range is 0.57MPa; the sandblasting time is 3min; The vertical distance between the sandblasting gun and the welding surface during sandblasting is 90mm; the angle between the sandblasting direction of the sandblasting gun and the welding surface can be flexibly adjusted within the range of 0-180° during the sandblasting process, so that each welding surface The roughness distribution at the point is uniform;

[0062] (3) Perform electroless nickel plating on the welding surface of the tantalum target and the copper back plate after ...

Embodiment 2

[0069] This embodiment provides a brazing method for a tantalum target and a copper back plate, the brazing method includes the following steps:

[0070] (1) Correct the warpage of the tantalum target so that the flatness of the target is ≤0.2mm;

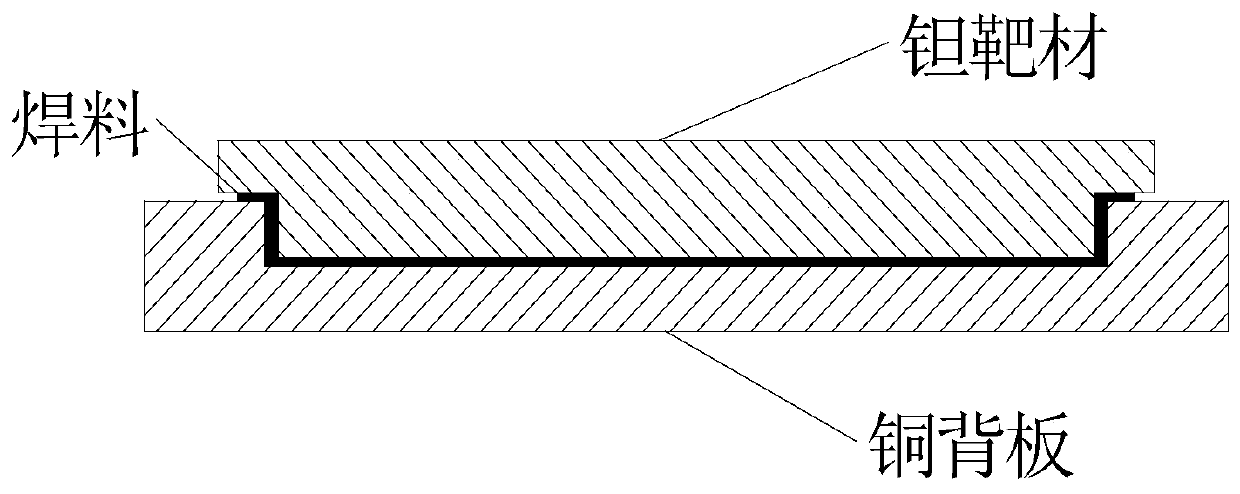

[0071] (2) A boss is set on the welding surface of the tantalum target, and a groove matching the boss is arranged on the welding surface of the copper back plate. The difference between the depth of the groove and the height of the boss is 0.5mm, and the groove is The diameter of the effective circle is 0.4mm larger than the equivalent circle diameter of the boss; then the surface sandblasting treatment is carried out independently on the welding surface of the tantalum target and the copper back plate; the sand grains used for the sandblasting treatment are No. The range is 0.57MPa; the sandblasting time is 3min; the vertical distance between the sandblasting gun and the welding surface is 90mm; the angle between the sandblasting ...

Embodiment 3

[0079] This embodiment provides a brazing method for a tantalum target and a copper back plate, the brazing method includes the following steps:

[0080] (1) Correct the warpage of the tantalum target so that the flatness of the target is ≤0.2mm;

[0081] (2) Set a boss on the welding surface of the tantalum target, and set a groove matching the boss on the welding surface of the copper back plate. The difference between the depth of the groove and the height of the boss is 0.4mm, and the groove is equal The diameter of the effective circle is 0.5mm larger than the equivalent circle diameter of the boss; then the surface of the welding surface of the tantalum target and the copper back plate is independently subjected to surface sandblasting treatment; the sand used for the sandblasting treatment is No. The range is 0.56MPa; the sandblasting time is 3.5min; the vertical distance between the sandblasting gun and the welding surface is 95mm; the angle between the sandblasting di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com