Fixing structure for embedded cooling oil tube, casting system and casting method

A fixed structure, pre-embedded technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of operator danger, explosion, easy floating, displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) The raw material of following mass percentage is taken: 40% of pig iron, steel scrap 35%, 25% of returned charge, carburizer: 0.9% of the total amount of pig iron, scrap steel, returned charge;

[0065] (2) Put all the pig iron and steel scrap into the smelting furnace, then add 0.9% carburant of the formula total amount; heating makes the charge melt, and after the charge is melted, add FeSi75-C ferrosilicon, the addition of ferrosilicon is 0.75% of the total mass of pig iron, scrap steel and returned materials to obtain the original molten iron, and continue to heat the original molten iron to 1490°C; the composition and mass percentage of the obtained original molten iron are C 3.58%, Si 1.45%, Mn0.24 %, P0.035%, S 0.023%, the rest is iron;

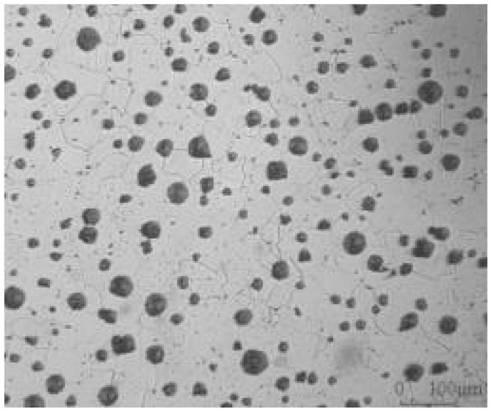

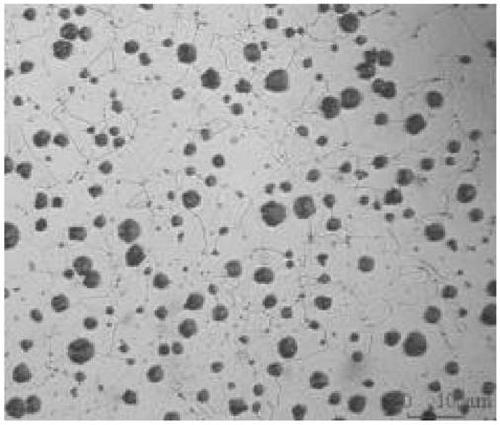

[0066] (3) The spheroidization is carried out by the flushing method. The spheroidizing dam on one side of the spheroidizing bag is firstly added with a spheroidizer and compacted, and then an inoculant with a particle size ...

Embodiment 2

[0080] (1) The raw materials of the following mass percentages are weighed: 35% of pig iron, 35% of steel scrap, 30% of recharge, recarburizer: 1.0% of the total amount of pig iron, scrap, and recycle;

[0081] (2) Put all the pig iron and steel scrap into the smelting furnace, then add a carburant with a total formula of 1.0%; heat to melt the charge, and add FeSi75-C ferrosilicon after the charge is melted, and the amount of ferrosilicon added is 0.67% of the total mass of pig iron, scrap steel and returned materials to obtain the original molten iron, and continue to heat the original molten iron to 1490°C; the composition and mass percentage of the obtained original molten iron are C 3.55%, Si 1.50%, Mn0.22 %, P0.033%, S 0.025%, the rest is iron;

[0082] (3) The spheroidization is carried out by the flushing method. The spheroidizing dam on one side of the spheroidizing bag is firstly added with a spheroidizer and compacted, and then an inoculant with a particle size of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com