Near-field microwave measurement system based on impedance measurement

A microwave measurement and impedance measurement technology, applied in the measurement of electrical variables, measurement devices, dielectric properties measurement and other directions, can solve the problems of slow test speed, no measurement, spatial resolution as low as 0.1μm, etc., to simplify motion control system, improve the accuracy of position control, and reduce the cost of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Factors such as the chemical composition of the liquid, ion concentration, and temperature can change the dielectric parameters of the liquid. By directly quantitatively measuring the dielectric parameters of liquids, parameters such as chemical composition, ion concentration and temperature can be measured without contact.

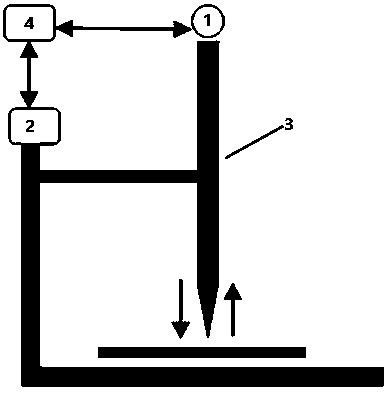

[0040] In an exemplary embodiment of the present invention, a near-field microwave measurement system for dielectric parameters of a liquid object to be measured is provided, with an operating frequency range of 20 GHz to 25 GHz. The system includes: a microwave network analysis system 1 , a position device 2 , a near-field microwave impedance sensor 3 and a data processing system 4 . The microwave network analysis system 1 is configured to generate a microwave signal and input it to the near-field microwave impedance sensor 3 to determine the complex impedance. The position device 2 is configured to fix the near-field microwave impedance sensor 3...

Embodiment 2

[0051] In the production or quality control of layered products such as glass, semiconductor wafers or PCB boards, high spatial resolution material parameters and surface morphology detection of layered objects can be used to feedback control process parameters and improve yield. Differences in material properties below the surface of the material target area alter the dielectric properties of the material target area. These tests should have the following characteristics: non-contact, non-destructive, fast, and high sensitivity. To reduce the size of the sensor probe, the near-field microwave measurement system uses the electromagnetic interaction between the sensor probe and the measured object in the near field, which can break through the diffraction limit and achieve a spatial resolution of less than λ / 2.

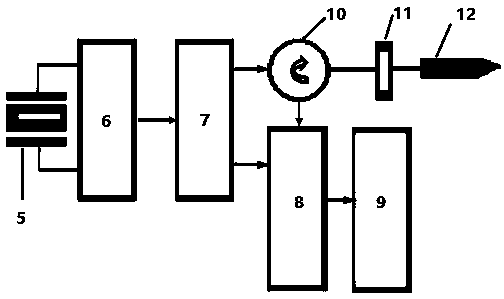

[0052] In an exemplary embodiment of the present invention, a near-field microwave measurement system for material parameters and surface topography of a layered objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com