Preparation method of iodinated fatty acid ethyl ester with stable quality

A technology of fatty acid ethyl ester and stable quality, which is applied in the preparation of carboxylate, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of difficult to obtain stable iodinated fatty acid ethyl ester, difficult to remove, difficult to crystallize, etc. , to achieve the effect that the color is not easy to exceed the standard, the quality is improved, and it is not easy to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

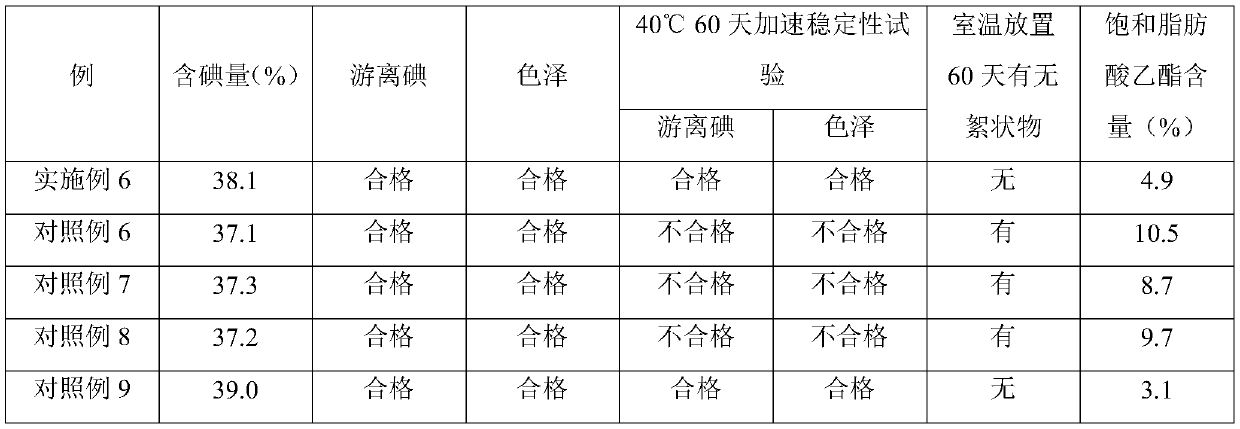

Examples

Embodiment 1

[0039] Take 100g of linseed oil (Yihai Kerry Co., Ltd., the same below) and preheat it to 75°C in a sandwich reactor (Shanghai Shendi Glass Instrument Co., Ltd., the same below); add 35mL of absolute ethanol (Sinopharm Chemical Reagent Co., Ltd. Company, analytically pure, the same below) and 1g sodium methylate (Sinopharm Chemical Reagent Co., Ltd., analytically pure, the same below), reacted for 2h to obtain the reaction solution; the reaction solution was moved to a separatory funnel, and allowed to stand for stratification; take the upper layer Unreacted absolute ethanol was recovered by distillation under reduced pressure, washed with distilled water until neutral and dried to obtain linseed oil fatty acid ethyl ester.

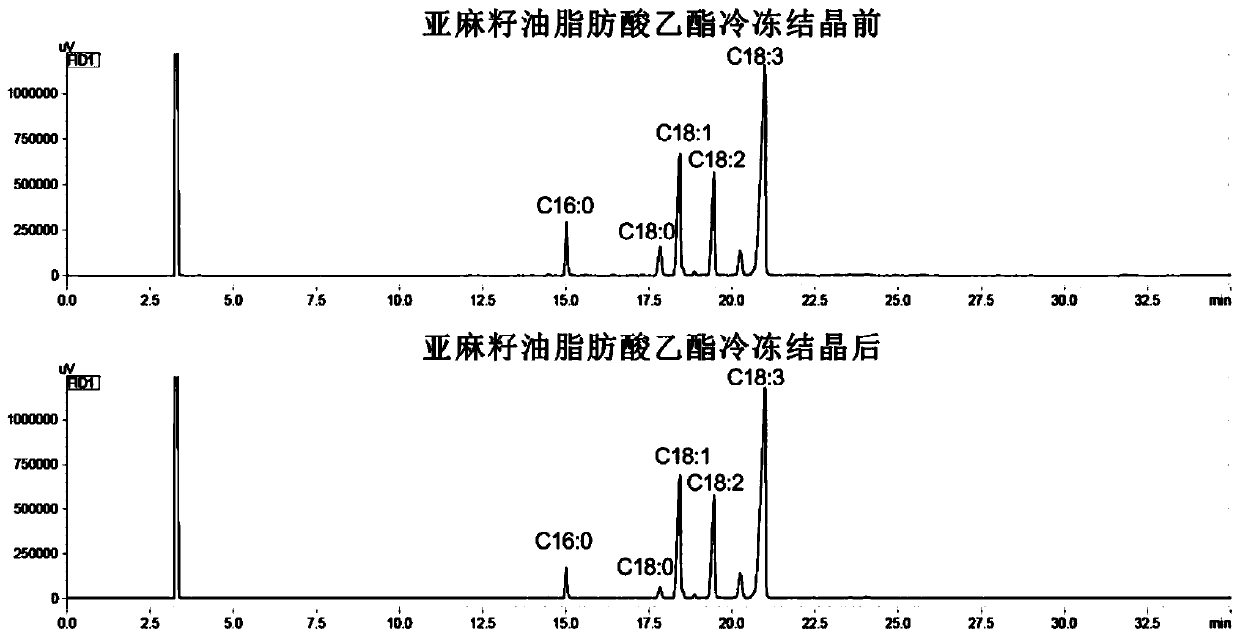

[0040]Mix linseed oil fatty acid ethyl ester and absolute ethanol uniformly at a volume ratio of 1:1, transfer to a low-temperature reaction kettle (German LAUD, the same below), lower the temperature to -25°C at a rate of 1°C per hour, and continue Keep ...

Embodiment 2

[0049] Take 50g perilla oil (Hebei Jiafeng Vegetable Oil Co., Ltd., the same below) and 50g rapeseed oil (Yihai Kerry Co., Ltd., the same below) in a sandwich reactor, preheat to 70°C, add 40mL of absolute ethanol, add 1.5g sodium ethylate (Sinopharm Chemical Reagent Co., Ltd., analytically pure, the same below), reacted for 1.5h to obtain a reaction solution; the reaction solution was moved to a separatory funnel, allowed to stand for stratification, and the upper layer was distilled under reduced pressure to reclaim unreacted absolute ethanol, washed with distilled water until neutral and dried to obtain fatty acid ethyl esters (perilla oil: rapeseed oil = 1:1).

[0050] Mix the above-mentioned fatty acid ethyl ester and absolute ethanol evenly according to the volume ratio of 1:1.5, transfer it to a low-temperature reaction kettle, and lower it to -20°C at a cooling rate of 2°C per hour, and continue to maintain the temperature at -20°C±0.5°C Keep it for 7 days and repeat o...

Embodiment 3

[0058] Take 100g of walnut oil (Hebei Jiafeng Vegetable Oil Co., Ltd., the same below) in a sandwich reactor, preheat to 80°C, add 45mL of absolute ethanol, add 2g of sodium hydroxide (Sinopharm Chemical Reagent Co., Ltd., analytically pure, the same below) ), reacted for 1.5h to obtain a reaction solution; the reaction solution was moved to a separatory funnel, allowed to stand for stratification, and the upper layer was taken for vacuum distillation to reclaim unreacted absolute ethanol, and washed with distilled water to neutrality and dried to obtain walnut oil fatty acid ethyl ester.

[0059] Mix the above-mentioned walnut oil fatty acid ethyl ester and absolute ethanol evenly according to the volume ratio of 1:2, transfer it to a low-temperature reaction kettle, and lower it to -18°C at a cooling rate of 0.5°C per hour, and continue to cool at -18°C±0.5°C Maintain the temperature for 8 days and repeat 3 times; filter with Buchner funnel while it is cold to get walnut oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com