Preparation method of foamed ceramic material, and foamed ceramic material and applications thereof

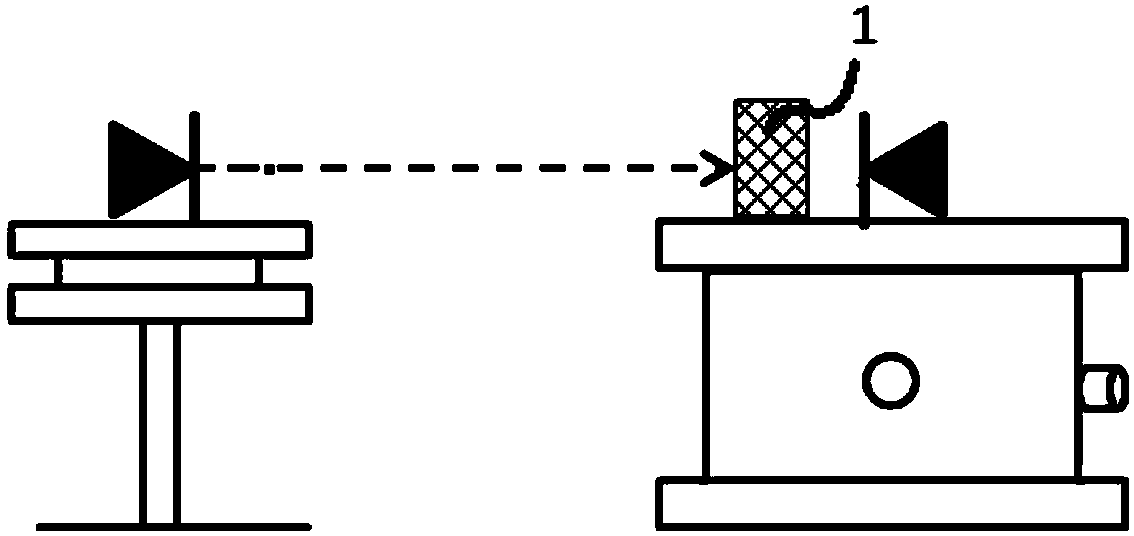

A foam ceramic and ceramic-based technology, applied in the field of optical absorption, can solve the problems of increased detection cost, high detector performance requirements, low optical signal transmittance, etc., achieve low production cost, good corrosion resistance, and enhanced optical signal The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

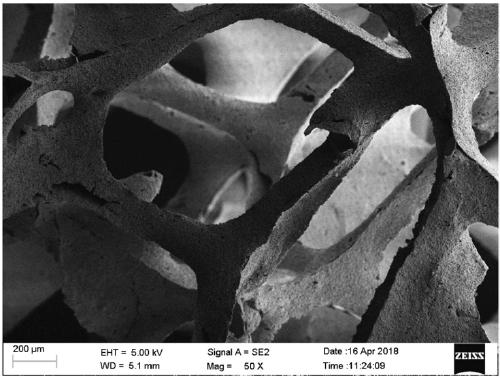

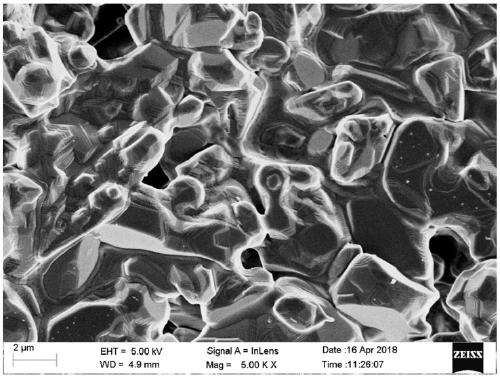

[0032] This embodiment records a preparation example of the foamed ceramic material, which specifically includes:

[0033] (1) Foam pretreatment: immerse polyurethane foam in a sodium hydroxide solution with a mass percentage of 20wt%, hydrolyze it at 50°C for 5 hours, repeatedly knead and rinse with water, and put it in mass percentage Soak in 10% carboxymethyl cellulose solution for 3 hours to change the surface properties of the polyurethane foam, take it out, squeeze to remove the excess carboxymethyl cellulose solution, wash with water, and dry to obtain modified polyurethane foam;

[0034] (2) Slurry configuration: Dissolve the dispersant in the solvent, add rheological agents, binders and sintering aids, and mix them evenly; then add the ceramic base material, pre-stir it for 15 minutes to make it uniform, and then add ammonia to improve its Fluidity, and then ultrasonically oscillate to make it evenly dispersed to obtain slurry. In this embodiment, the dispersant is gum ar...

Embodiment 2

[0039] This embodiment records another preparation example of the foamed ceramic material, which specifically includes:

[0040] (1) Foam pretreatment: immerse polyurethane foam in a sodium hydroxide solution with a mass percentage of 10wt%, hydrolyze it at 40°C for 2 hours, repeatedly knead and rinse with water, and put it in mass percentage Soak it in 0.5% carboxymethyl cellulose solution for 5 hours to change the surface properties of the polyurethane foam, take it out, squeeze to remove the excess carboxymethyl cellulose solution, wash with water, and dry to obtain modified polyurethane foam;

[0041] (2) Slurry configuration: Dissolve the dispersant in the solvent, add rheological agents, binders and sintering aids, and mix well; then add the ceramic base material, pre-stir it for 5-15 minutes to make it uniform, and then add ammonia Improve its fluidity, and then ultrasonically oscillate to make it evenly dispersed to obtain slurry. In this embodiment, the dispersant is gum ...

Embodiment 3

[0046] This embodiment records another preparation example of the foamed ceramic material, which specifically includes:

[0047] (1) Foam pretreatment: immerse the polyurethane foam in a sodium hydroxide solution with a mass percentage of 15wt%, hydrolyze it at 60°C for 3 hours, knead repeatedly and rinse with water, then put in the surfactant SurfynolTG Soak it in the medium for 1 hour to change the surface properties of the polyurethane foam, take it out, squeeze to remove the excess carboxymethyl cellulose solution, wash with water, and dry to obtain the modified polyurethane foam;

[0048] (2) Slurry configuration: Dissolve the dispersant in the solvent, add rheological agents, binders and sintering aids, and mix well; then add the ceramic base material, pre-stir it for 5-15 minutes to make it uniform, and then add ammonia Improve its fluidity, and then ultrasonically oscillate to make it evenly dispersed to obtain slurry. In this embodiment, the dispersant is Darvanc (25% pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com