Iron-cobalt-nickel-copper-based high-entropy alloy water electrolysis catalytic material and preparation method thereof

A technology of catalytic materials and copper-based alloys, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as low cost, poor electrical conductivity, and low catalytic activity , to achieve the effect of improving catalytic activity, good stability and high active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

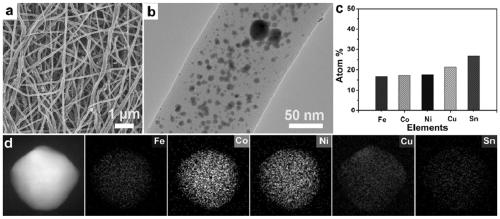

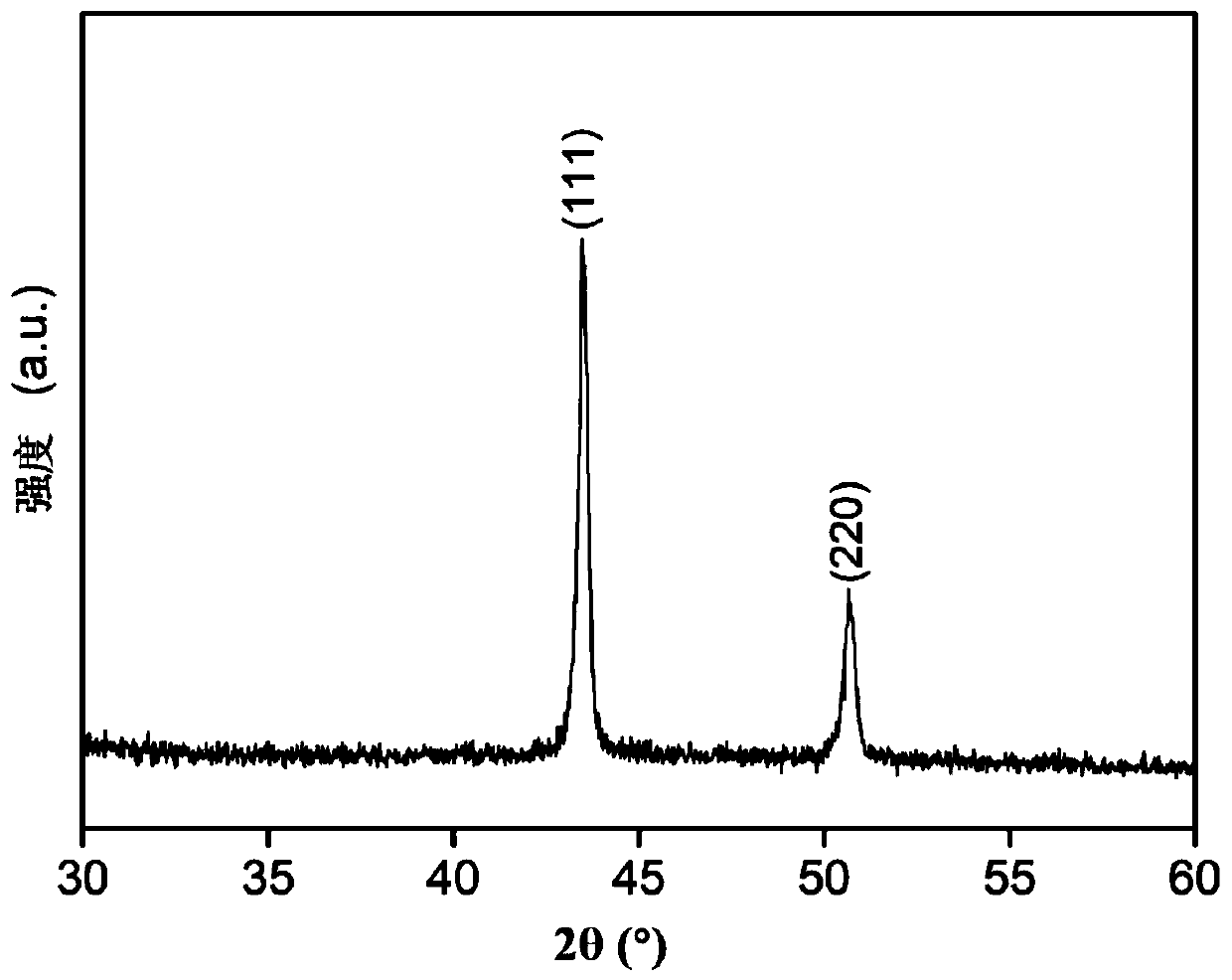

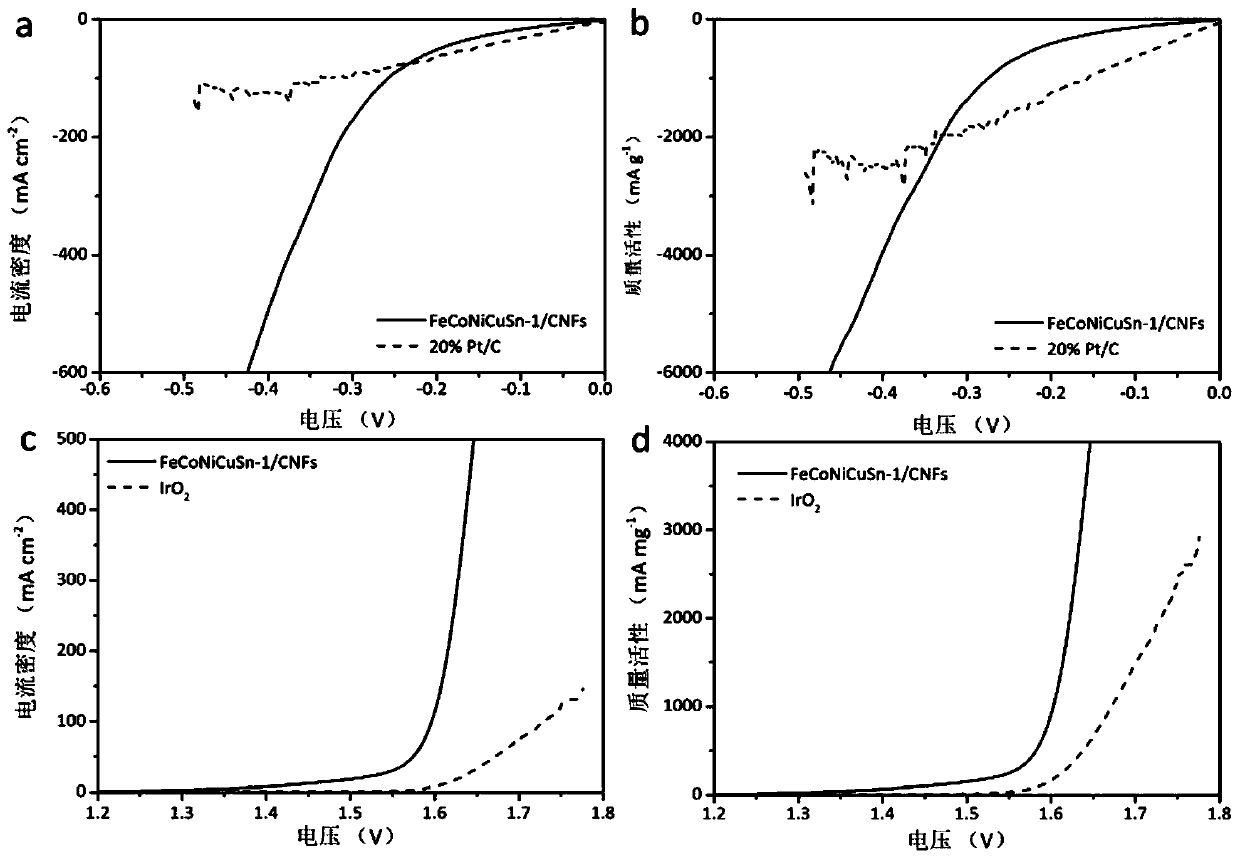

[0054] Preparation of FeCoNiCuSn HEA / CNFs Catalytic Materials for Electrolysis of Water

[0055] (1) Get 0.1mmol ferric chloride, 0.1mmol cobalt chloride, 0.1mmol nickel chloride, 0.1mmol cupric chloride, 0.1mmol tin chloride and 0.2g dicyandiamide to join 30g mass fraction and be 18wt% polypropylene In the nitrile / N,N-dimethylformamide solution, stir evenly by magnetic force, and then use the electrospinning method to spin the solution, control the spinning voltage to 15kV, and the distance from the receiving device to the pillow is 15cm, the solution The flow rate was 0.05 mL / min to obtain a mixed nanofiber membrane.

[0056] (2) Get 0.5g of the mixed nanofiber membrane prepared in step (1) and put it into a corundum boat, and place it in the middle of the tube furnace. Firstly, the temperature was raised to 230° C. at a heating rate of 20° C. / min, and kept for 3 hours in an air atmosphere. After the heat preservation is over, in an argon atmosphere, the temperature is rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com