Tea concentrated solution and processing method thereof

A technology of tea concentrate and instant tea powder, which is applied in the field of food processing, can solve the problems of affecting the sensory quality of products, prone to precipitated polymers, and poor stability, and achieves the effects of convenient storage, improved flavor, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

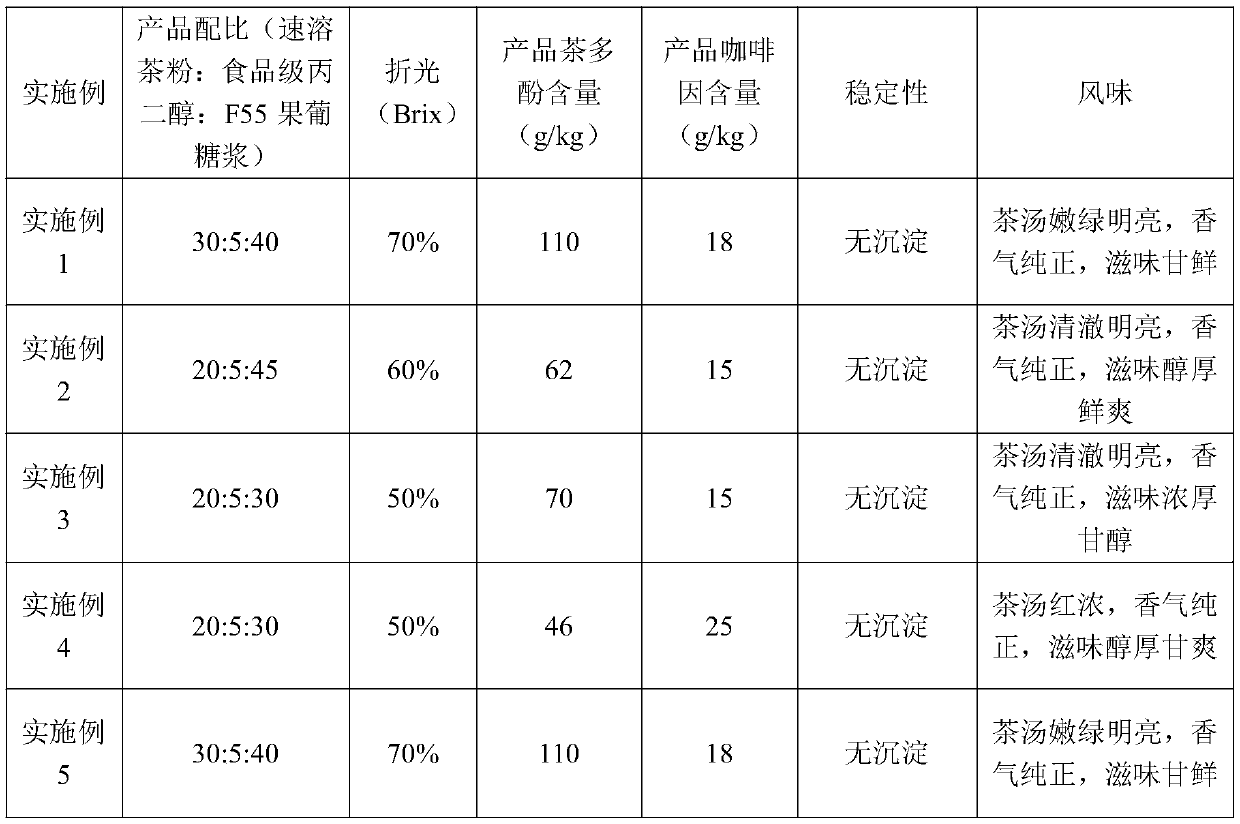

Examples

Embodiment 1

[0030] (1) Material selection: choose instant green tea powder 30g, F55 fructose syrup 40g and food grade propylene glycol 5g for subsequent use with a solubility of 50g / 100ml;

[0031] (2) Preparation: Mix the above-mentioned instant green tea powder, food-grade propylene glycol and F55 fructose syrup, add 80°C pure water to 100g, stir the liquid until it is completely dissolved, filter the liquid through a filter membrane to obtain a tea concentrate ;

[0032] (3) Sterilization: Fill the tea concentrate obtained in step (2) into an aseptic bag, and perform high-temperature sterilization at 95° C. for 5 minutes;

[0033] (4) Refrigeration: Store the sterilized tea concentrate in a refrigerator at 4°C.

Embodiment 2

[0035] (1) Material selection: choose instant black tea powder 20g, F55 fructose syrup 45g and food grade propylene glycol 5g for subsequent use with a solubility of 50g / 100ml;

[0036] (2) Preparation: Mix the above-mentioned instant black tea powder, food-grade propylene glycol and F55 fructose syrup, add 80°C pure water to 100g, stir the liquid until it is completely dissolved, filter the liquid through a filter membrane to obtain a tea concentrate ;

[0037] (3) Sterilization: Fill the tea concentrate obtained in step (2) into an aseptic bag, and perform high-temperature sterilization at 95° C. for 5 minutes;

[0038] (4) Refrigeration: Store the sterilized tea concentrate in a refrigerator at 4°C.

Embodiment 3

[0040] (1) material selection: choose 20g of instant oolong tea powder, 30g of F55 fructose syrup and 5g of food grade propylene glycol with a solubility of 30g / 100ml for subsequent use;

[0041] (2) Preparation: Mix the above-mentioned instant oolong tea powder, food-grade propylene glycol and F55 fructose syrup, add 80°C pure water to 100g, stir the liquid until it is completely dissolved, filter the liquid through a filter membrane to obtain a tea concentrate ;

[0042] (3) Sterilization: Fill the tea concentrate obtained in step (2) into an aseptic bag, and perform high-temperature sterilization at 95° C. for 5 minutes;

[0043] (4) Refrigeration: Store the sterilized tea concentrate in a refrigerator at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com