Combined drying unit for continuous vacuum frying and frying drying method

A technology of vacuum frying and combined drying, which is applied in application, oil/fat baking, food preservation, etc. It can solve the problems that cannot meet the health requirements of food, the products are difficult to achieve uniform drying, and the materials in the frying cabin cannot be accommodated. Achieve the effect of realizing product quality characteristics, realizing continuous production, and improving production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the invention, and these aspects of the invention can be practiced without these specific details.

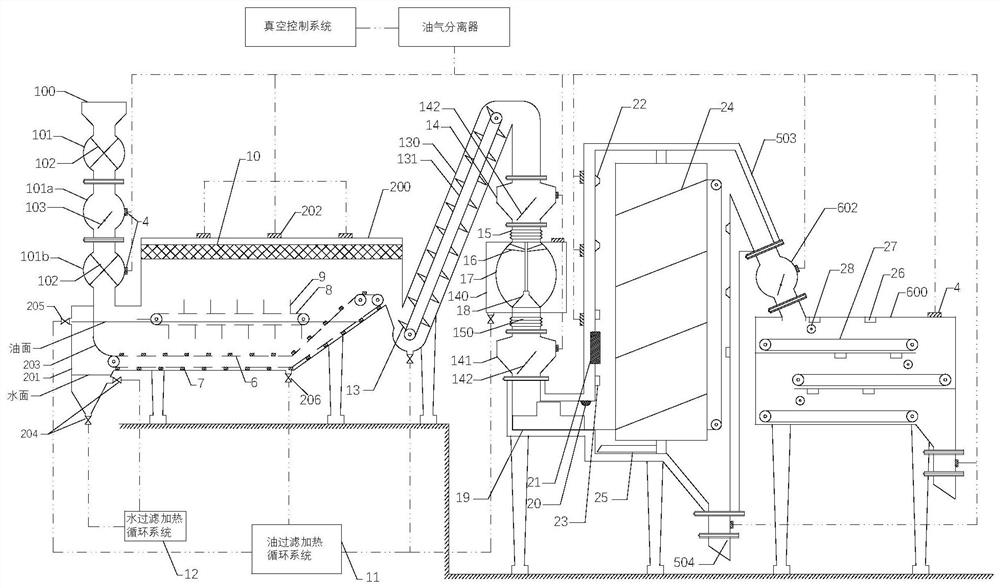

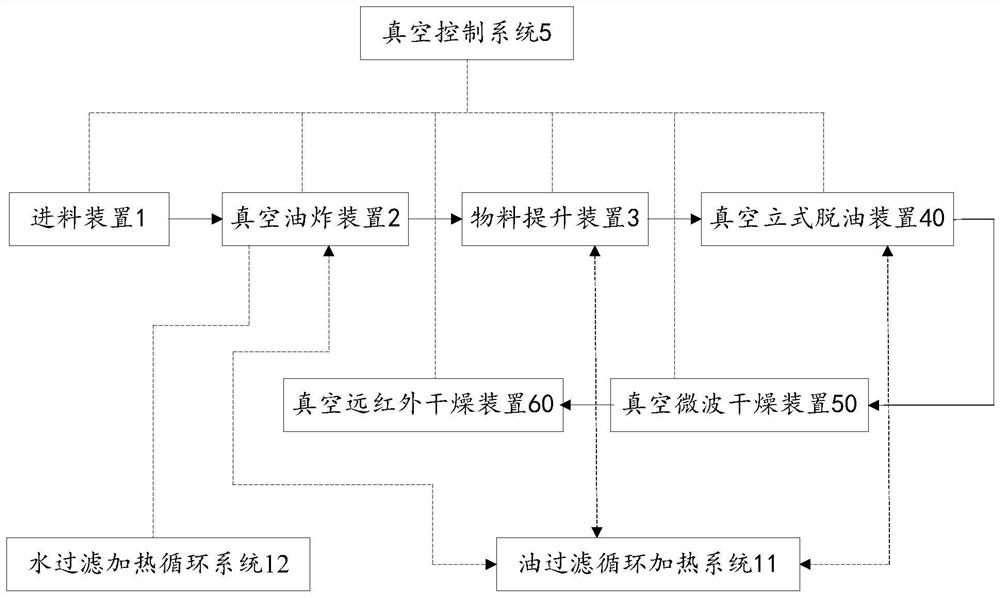

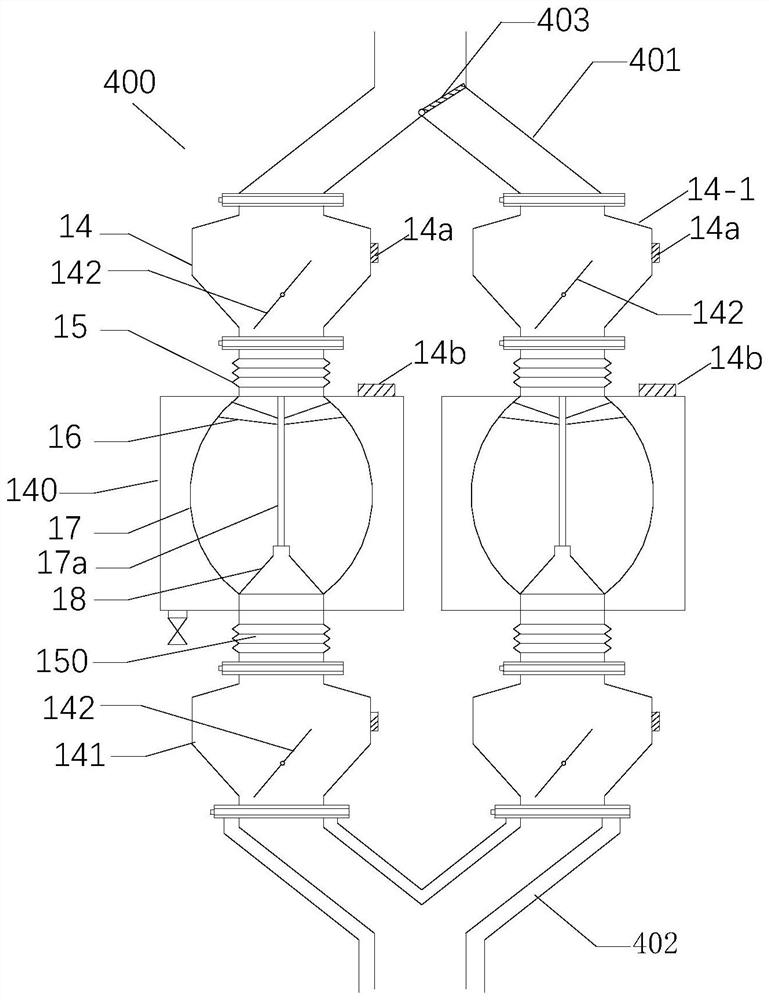

[0025] Such as figure 1 and figure 2 As shown, a combined drying unit for continuous vacuum frying according to the present invention includes a feeding device, a vacuum frying device, an oil filtration circulation heating system 11, a water filtration heating circulation system 12, a material lifting device, a vacuum vertical type deoiling device, vacuum microwave drying device, vacuum far-infrared drying device and vacuum control system, the discharge end of the feeding device is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com