Method for preparing instant tea through extraction by using supercritical carbon dioxide and separation by using multilayer membrane

A carbon dioxide, supercritical technology, applied in tea, application, tea extraction, etc., can solve the problems of inability to remove unhelpful substances, low extraction efficiency, etc., to reduce pesticide residues and heavy metal content, overcome selective dissolution, and improve extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

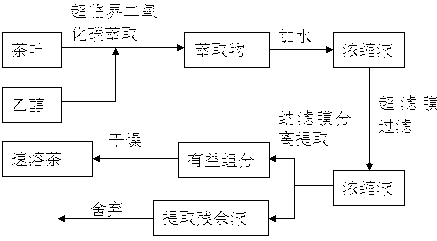

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 The preparation of Luzhou-flavor Tieguanyin instant tea

[0041] Luzhou-flavor Tieguanyin is a kind of oolong tea, mainly produced in Anxi. Tea should be made according to the unique traditional processing technology, with the quality characteristics of Tieguanyin. Luzhou-flavor Tieguanyin sensory indicators are divided into five grades.

[0042] 1. Select Luzhou-flavor Tieguanyin super-grade tea 1KG as a specimen, use supercritical carbon dioxide, add an appropriate amount of ethanol as an entrainer at a temperature of 30°C and a pressure of 30MPa, humidify with carbon dioxide, and extract fully to obtain an extract.

[0043] 2. Add water, carry out ultrafiltration with a 50,000 molecular weight ultrafiltration membrane, remove macromolecular impurities, and obtain a tea concentrate. The molecular weight of most germs is above 50,000, so the ultrafiltration process can remove germs.

[0044] 3. Use a nanofiltration membrane with a molecular weight of ...

Embodiment 2

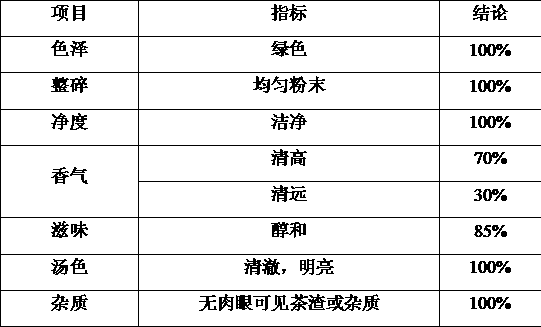

[0051] Sensory evaluation results

[0052] Randomly select 100 people, drink the fragrance type instant green tea that this patent application method makes, after calculating the average, draw the following table 1:

[0053]

Embodiment 3

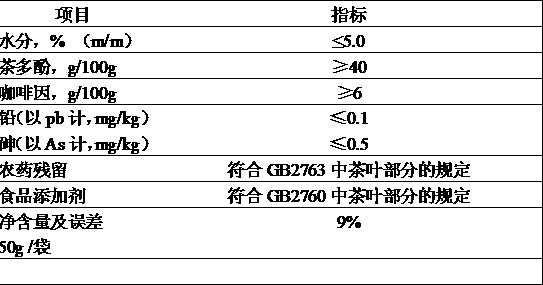

[0055] The physical and chemical indexes of the instant Pu'er tea that this patent application method makes are as shown in table 2:

[0056] Table 2

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com