Method for brewing dry fermented wine by fermenting mixed juice of Nanguo pear

A technology for fermenting wine and fruit pears, which is applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc. It can solve the problem that clarification treatment affects the fullness of wine body, and the stability, flavor and taste of finished wine cannot be reflected Variety characteristics, imperfect anti-oxidation protection measures, etc., to achieve the effects of ensuring clarity and stability, inhibiting oxidative browning, and reducing local temperature accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

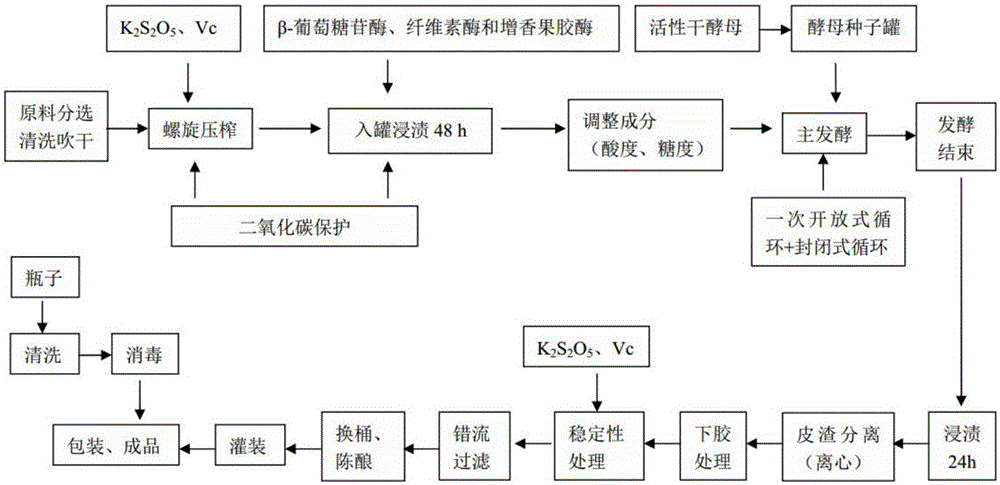

[0032] Production of Nanguo Pear Wine

[0033] The production steps of the Nanguo pear wine of the present embodiment are as follows:

[0034] (1) Select 1,000 catties of Nanguo pears that have been matured and stored for a period of time, clean them, dry the surface moisture with cold wind, crush them with a screw press, collect the juice and pomace, and the ratio of pomace to juice is 1:1 ( kg / L) During the crushing process, add 20 g of potassium metabisulfite dissolved in Nanguo pear juice and 8 g of vitamin C at 20 mg / L at a rate of 50 mg / L, and at the same time add carbon dioxide at a rate of 0.5 kg per thousand liters of pulp Gas for protection.

[0035] (2) Dipping with skin: add 20g of activated β-glucosidase, cellulase and aroma-enhancing pectinase (1:2:2) to the fruit pulp at a ratio of 50mg / L, under the condition of carbon dioxide protection Next, charge 0.5kgCO per thousand liters of pulp 2 gas, impregnated at a temperature of 3°C to 8°C for 42h.

[0036] (3) Sug...

Embodiment 2

[0048] The production steps of the Nanguo pear wine of the present embodiment are as follows:

[0049] (1) raw material processing: processing steps are the same as embodiment 1 step (1), just add the potassium metabisulfite 24g that dissolves in Nanguo pear juice and the vitamin C12g of 30mg / L by the ratio of 60mg / L in crushing process.

[0050] (2) Skin dipping: same as step (2) in Example 1, but the dipping time is 36h.

[0051] (3) sugar content adjustment: with embodiment 1 step (3).

[0052] (4) Establishment of the seed tank: After soaking the skin for 24 hours, take 90L of fruit pulp and put it in a small tank for later use, and activate the activated dry yeast. The activation method is: select the yeast dosage according to the ratio of 600mg / L, according to 1: The ratio of yeast to water is 10. Dissolve the yeast in pure water at 36°C-38°C, stir well, activate for 15 minutes, take 5L of Nanguo pear pulp, add it to the activated yeast in 5 times, measure the activatio...

Embodiment 3

[0063] The production steps of the Nanguo pear wine of the present embodiment are as follows:

[0064] (1) raw material processing: processing steps are the same as embodiment 1 step (1), just add the potassium metabisulfite 28g that dissolves in Nanguo pear juice and the vitamin C12g of 30mg / L by the ratio of 70mg / L in crushing process.

[0065] (2) Skin dipping: same as step (2) in Example 1, but the dipping time is 42h.

[0066] (3) sugar content adjustment: with embodiment 1 step (3).

[0067] (4) Establishment of the seed tank: After soaking the skin for 24 hours, take 100L of fruit pulp and put it in a small tank for later use, and activate the activated dry yeast. The ratio of yeast to water is 10. Dissolve the yeast in pure water at 36°C-38°C, stir well, activate for 15 minutes, take 6L of Nanguo pear pulp, add it to the activated yeast in 6 times, measure the activation solution while adding When the temperature of the fruit pulp drops by 5°C as the breaking point, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com