Bamboo-based porous carbon/manganese dioxide nano composite electrode material for super capacitor and preparation method thereof

A supercapacitor and manganese dioxide technology, applied in the direction of hybrid capacitor electrodes, can solve the problems of single product structure, low capacitance performance, environmental pollution, etc., and achieve the effects of simple synthesis process, improved performance, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

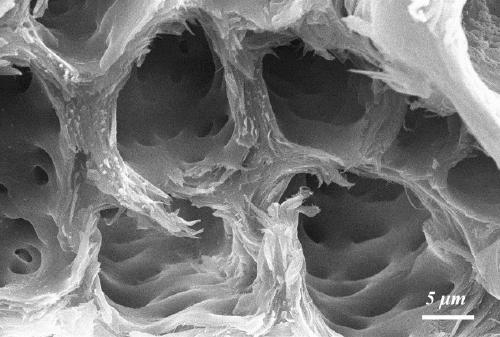

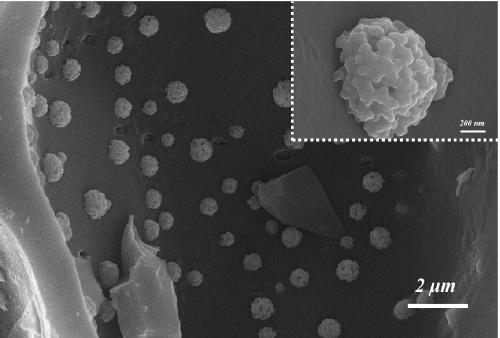

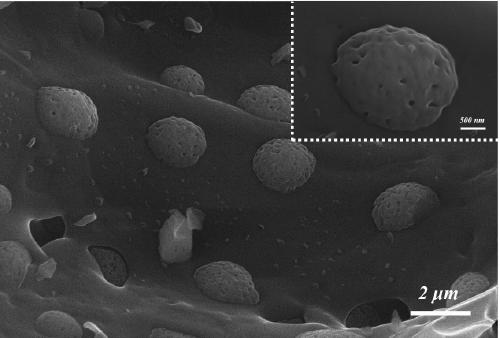

[0020] The bamboo is processed into small pieces, cleaned to remove impurities, and then dried. Take about 2 g of small bamboo pieces and place them in a boat crucible, and carbonize in a tube furnace under a nitrogen atmosphere. The heating rate is 5℃ / min, and the carbonization temperature is 800℃, the carbonization time is 120 min. The carbonized product is mixed with potassium hydroxide solution, the ratio of alkali to carbon is 1:4, and it is immersed in a nickel crucible for 5 hours at 90°C for high temperature activation in a nitrogen atmosphere. The heating rate is 5°C / min and the activation temperature is 800 ℃, the activation time is 120 min, and the activated product is washed to neutrality and dried to obtain bamboo-based porous carbon. The bamboo-based porous carbon was immersed in a potassium permanganate / manganese sulfate solution with a molar ratio of 1:3, and placed in an autoclave at 150°C for 24 hours. The product was naturally cooled to room temperature and c...

Embodiment 2

[0023] The bamboo is processed into small pieces, cleaned to remove impurities, and then dried. Take about 2 g of small bamboo pieces and place them in a boat crucible, and carbonize in a tube furnace under a nitrogen atmosphere. The heating rate is 5℃ / min, and the carbonization temperature is 800℃, the carbonization time is 120 min. The carbonized product was mixed with potassium hydroxide solution, the ratio of alkali to carbon was 1:2, and it was immersed in a nickel crucible for 5 h at 90°C for high-temperature activation in a nitrogen atmosphere. The heating rate was 5°C / min and the activation temperature was At 800°C, the activation time is 120 minutes, and the activated product is washed to neutrality and dried to obtain bamboo-based porous carbon. The bamboo-based porous carbon was immersed in a potassium permanganate / manganese sulfate solution with a molar ratio of 1:3, and placed in an autoclave at 150°C for 24 hours. The product was naturally cooled to room temperatu...

Embodiment 3

[0026] The bamboo is processed into small pieces, cleaned to remove impurities, and then dried. Take about 2 g of small bamboo pieces and place them in a boat crucible, and carbonize in a tube furnace under a nitrogen atmosphere. The heating rate is 5℃ / min, and the carbonization temperature is 800℃, the carbonization time is 120 min. The carbonized product was mixed with potassium hydroxide solution, the ratio of alkali to carbon was 1:4, and it was immersed in a nickel crucible for 5 hours at 90℃ for high-temperature activation in a nitrogen atmosphere. The heating rate was 5℃ / min and the activation temperature was 700℃, activation time is 120min, and the activated product is washed to neutrality and dried to obtain bamboo-based porous carbon. The bamboo-based porous carbon was immersed in a potassium permanganate / manganese sulfate solution with a molar ratio of 1:3, and placed in an autoclave at 150°C for 24 hours. The product was naturally cooled to room temperature and cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com