Method for preparing glyceride rich in arachidonic acid by two-step enzyme method, and product prepared by method

A technology of glyceryl tetraenoic acid and arachidonic acid, applied in the field of oil processing, can solve the problems of low content of arachidonic acid, no reports on preparation, etc., and achieve the effects of improving digestion and absorption efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

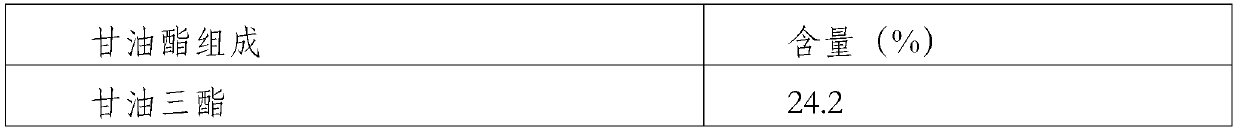

[0027] (1) The microbial oil rich in arachidonic acid and ethanol are mixed according to the molar ratio of 1:3, add in the sealable batch reactor, and add the Lipozyme RM IM of 12wt% wherein, at temperature The fatty acid composition of the obtained intermediate enzymatic hydrolysis product is shown in Table 1 below under the condition of 25° C. and a stirring rate of 400 rpm for 4 hours.

[0028] The fatty acid composition of table 1 intermediate enzymatic hydrolysis product

[0029]

[0030]

[0031] (2) After vacuum distillation and molecular distillation are used to remove the ethanol and fatty acid ethyl ester of the intermediate enzymatic hydrolysis product respectively, the intermediate enzymatic hydrolysis product and glycerin are mixed in a batch reactor according to the molar ratio of 1:3, and are added to the Add 3wt% Novozym 435, and react for 18 hours at a temperature of 70° C. and a stirring rate of 600 rpm. The composition of the obtained monoglyceride pr...

Embodiment 2

[0045] (1) The microbial oil rich in arachidonic acid and ethanol are mixed according to the molar ratio of 1:6, add in the sealable batch reactor, and add the Lipozyme TL IM of 8wt% wherein, at temperature The reaction was sealed for 8 hours at 35°C and a stirring rate of 600 rpm, and the fatty acid composition of the obtained intermediate enzymatic hydrolysis product was shown in Table 6 below.

[0046] The fatty acid composition of table 6 intermediate enzymatic hydrolysis product

[0047]

[0048]

[0049] (2) After vacuum distillation and molecular distillation are used to remove the ethanol and fatty acid ethyl ester of the intermediate enzymatic hydrolysis product respectively, the intermediate enzymatic hydrolysis product and glycerol are mixed in a batch reactor according to the ratio of 1:5 in molar ratio, and poured into it Add 8wt% Novozym 435 and react for 12 hours at a temperature of 50° C. and a stirring rate of 600 rpm. The composition of the obtained mon...

Embodiment 3

[0063] (1) The microbial oil rich in arachidonic acid and ethanol are mixed according to the molar ratio of 1:9, add in the sealable batch reactor, and add 4wt% Lipase AY-30SD wherein, at temperature The fatty acid composition of the obtained intermediate enzymolysis product is shown in Table 11 below under the condition of 45°C and a stirring rate of 800rpm for 12 hours.

[0064] Fatty acid composition of table 11 intermediate enzymatic hydrolysis product

[0065]

[0066] (2) After vacuum distillation and molecular distillation are used to remove the ethanol and fatty acid ethyl ester of the intermediate enzymatic hydrolysis product respectively, the intermediate enzymatic hydrolysis product and glycerol are mixed in a batch reactor according to the ratio of 1:6 in molar ratio, and poured into it Add 12wt% of Novozym 435 and react for 6 hours at a temperature of 30°C and a stirring rate of 400rm. The composition of the obtained monoglyceride product is shown in Table 12 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com