Lead sulfate waste desulfurization device and lead sulfate waste desulfurization process

A desulfurization device and lead sulfate technology, applied in the direction of lead carbonate, calcium/strontium/barium sulfate, etc., can solve the problems of increasing costs, affecting economic benefits, and difficult sales, so as to reduce consumption, improve gypsum quality, reduce deposition or Fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

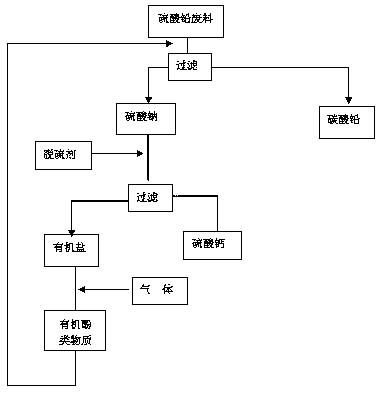

Method used

Image

Examples

Embodiment 1

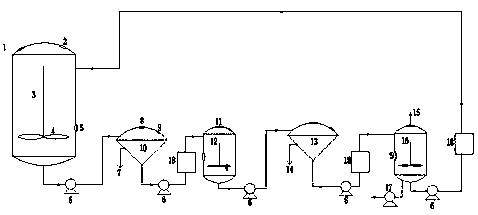

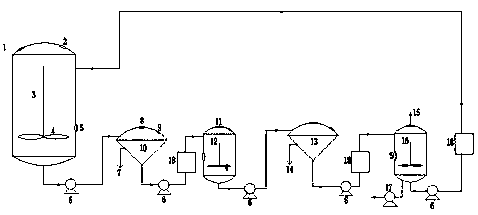

[0050] Such as Figure 1-2 Described, a kind of lead sulfate waste desulfurization equipment comprises desulfurization tank 3, conversion tank 12, carbonization tank 16, filter, pump 6, liquid storage tank 18 and delivery pipe; Desulfurization tank 3, conversion tank 12 and carbonization tank 16 Stirring device 4, acid-base thermometer 5 and heater are arranged inside the tank, and the heater is arranged on the stirring device 4 or the inner wall of the tank; Remove the sealing cover, and the observation hole is provided with a sealed transparent cover; the side wall of the tank body is equipped with an acid-base thermometer 5 for detecting the temperature and pH of the solution in the tank body; the lower part of the tank body is equipped with a discharge port, and the desulfurization tank is observed Hole 2 is used to observe the reaction of the solution in the tank.

[0051] The filter includes a first filter 10 and a second filter 13, the upper part of the filter is provi...

Embodiment 2

[0069] The above-mentioned lead sulfate waste desulfurization equipment is used for lead sulfate waste desulfurization treatment, and a commercially available valve-regulated sealed lead-acid battery with a specification of 12V and 55Ah is crushed and separated to obtain lead paste and waste sulfuric acid solution. According to the traditional chemical titration analysis of the lead paste, the lead-containing components and contents thereof are 9.6% of Pb, 14.5% of PbO, 34.8% of PbO2 and 38.7% of PbSO4. Then 1 kg of lead plaster is subjected to desulfurization reaction, including the processing process:

[0070] Add the lead sulfate waste and 0.6M sodium carbonate aqueous solution into the desulfurization tank 3 at a solid-to-liquid ratio of 3:1, heat to 70°C, and stir for 1.5 hours; after the reaction is completed, the pH value of the solution in the conversion tank 12 is controlled In 7-7.5, the solution is pumped into the membrane filter press for liquid-solid separation, a...

Embodiment 3

[0075] Adopt the lead sulfate waste desulfurization equipment in embodiment 1 to carry out the lead sulfate waste desulfurization treatment, take the by-product washed down during the acid leaching process in the positive plate manufacturing stage of a certain lead-acid battery production company in Hunan, and obtain the lead-containing components and content therein through analysis They are: Pb content 9.5%, PbO content 17.2%, PbSO4 content 32.4% and moisture content 37.3%. The desulfurization reaction is carried out by the positive pole leaching acid by-product, and the treatment process is as follows:

[0076] Add the lead sulfate waste and 0.5M sodium carbonate aqueous solution into the desulfurization tank 3 at a solid-to-liquid ratio of 3:1, heat to 75°C, and stir for 1.5 hours; after the reaction is completed, the pH value of the solution in the conversion tank 12 is controlled In 7-7.5, the solution is pumped into the membrane filter press for liquid-solid separation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com