Grating label production process

A production process and grating technology, applied in the field of grating mark production process, can solve problems such as reducing production quality, affecting printing effect, unable to guarantee printing quality, etc., and achieving the effect of improving environmental protection performance and protecting ink layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A grating label production process, comprising the following steps in turn:

[0028] S1: a printing step; the label paper is fixed and flattened, and at the same time, the multi-unit label image is printed on the label paper by using the image data for generating the label image;

[0029] S2: Checking step; check the label image printed on the printing medium and use a single label paper as a template to set an arrangement number based on a single printing unit;

[0030] S3: storing step; storing the layout information for determining the arrangement position when a plurality of label images are arranged on the printed medium;

[0031] S4: Secondary processing step; drying, bronzing and glazing of semi-finished labels in sequence;

[0032] S5: Waste discharge and cutting step; the work of checking and cutting off the labels of semi-finished products.

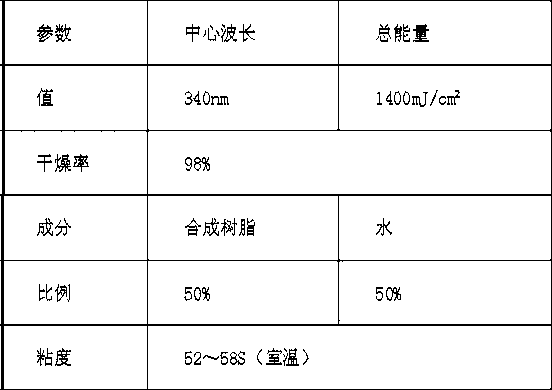

[0033] Wherein, the secondary processing step specifically includes: placing the semi-finished label in a UV heating ...

Embodiment 2

[0038] A grating label production process, comprising the following steps in turn:

[0039] S1: a printing step; the label paper is fixed and flattened, and at the same time, the multi-unit label image is printed on the label paper by using the image data for generating the label image;

[0040] S2: Checking step; check the label image printed on the printing medium and use a single label paper as a template to set an arrangement number based on a single printing unit;

[0041] S3: storing step; storing the layout information for determining the arrangement position when a plurality of label images are arranged on the printed medium;

[0042] S4: Secondary processing step; drying, bronzing and glazing of semi-finished labels in sequence;

[0043] S5: Waste discharge and cutting step; the work of checking and cutting off the labels of semi-finished products.

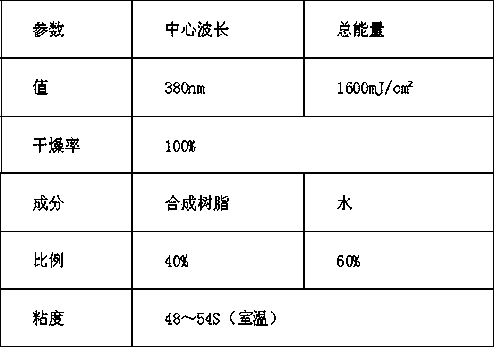

[0044] Wherein, the secondary processing step specifically includes: placing the semi-finished label in a UV heating ...

Embodiment 3

[0049] A grating label production process, comprising the following steps in turn:

[0050] S1: a printing step; the label paper is fixed and flattened, and at the same time, the multi-unit label image is printed on the label paper by using the image data for generating the label image;

[0051] S2: Checking step; check the label image printed on the printing medium and use a single label paper as a template to set an arrangement number based on a single printing unit;

[0052] S3: storing step; storing the layout information for determining the arrangement position when a plurality of label images are arranged on the printed medium;

[0053] S4: Secondary processing step; drying, bronzing and glazing of semi-finished labels in sequence;

[0054] S5: Waste discharge and cutting step; the work of checking and cutting off the labels of semi-finished products.

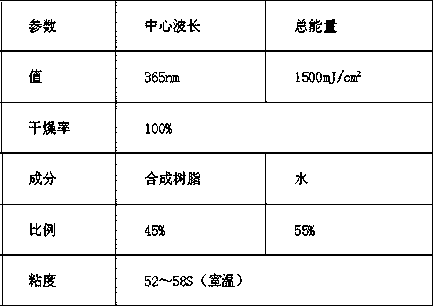

[0055] Wherein, the secondary processing step specifically includes: placing the semi-finished label in a UV heating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com