Nonaqueous electrolyte battery and battery pack

A non-aqueous electrolyte and battery technology, applied in the direction of non-aqueous electrolyte batteries, electrolytes, battery electrodes, etc., can solve problems such as battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0026] According to the first embodiment, a nonaqueous electrolyte battery is provided. The nonaqueous electrolyte battery includes a positive electrode, a negative electrode, and a nonaqueous electrolyte. The positive electrode has a positive electrode active material-containing layer. The positive electrode active material-containing layer contains lithium-manganese composite oxide particles and lithium-cobalt composite oxide particles having a spinel crystal structure. The negative electrode contains titanium-containing oxides. The nonaqueous electrolyte contains propionate. The non-aqueous electrolyte battery satisfies the following formulas: 0.8≤p / n≤1.2 and 1≤w / s≤60. p is the capacity per unit area of the positive electrode [mAh / cm 2 ]. n is the capacity per unit area of the negative electrode [mAh / cm 2 ]. w is the content of propionate in the non-aqueous electrolyte, and is in the range of 10% by weight or more and 60% by weight or less. s is the average part...

no. 2 Embodiment approach

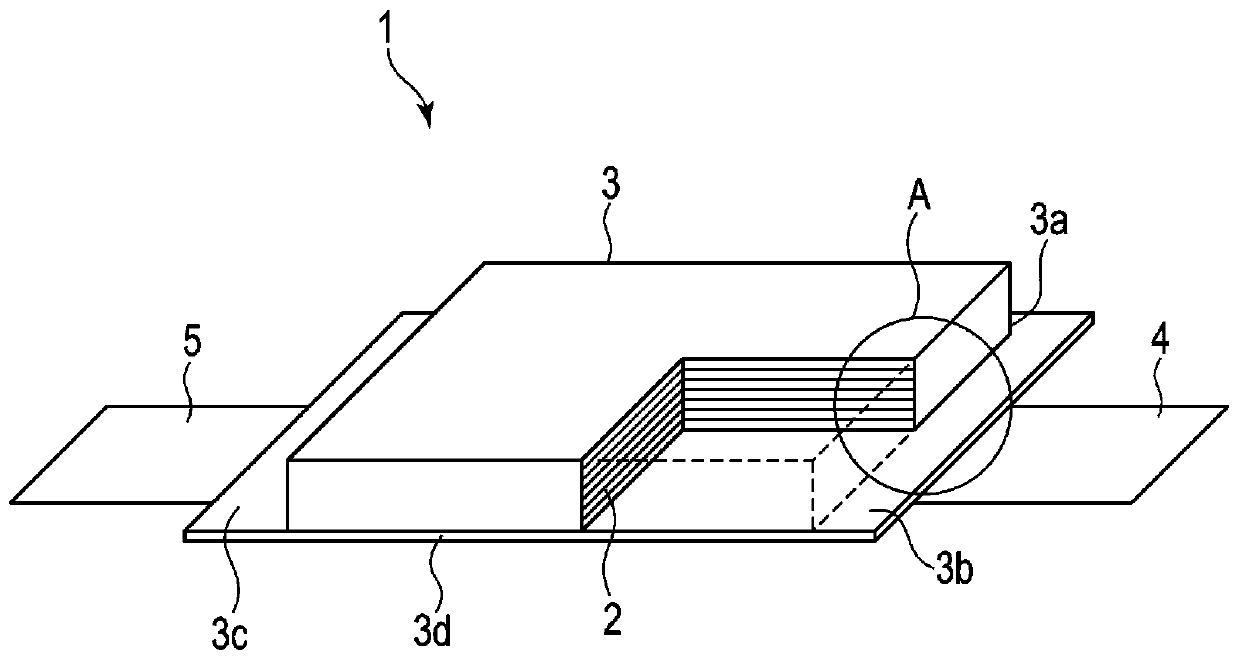

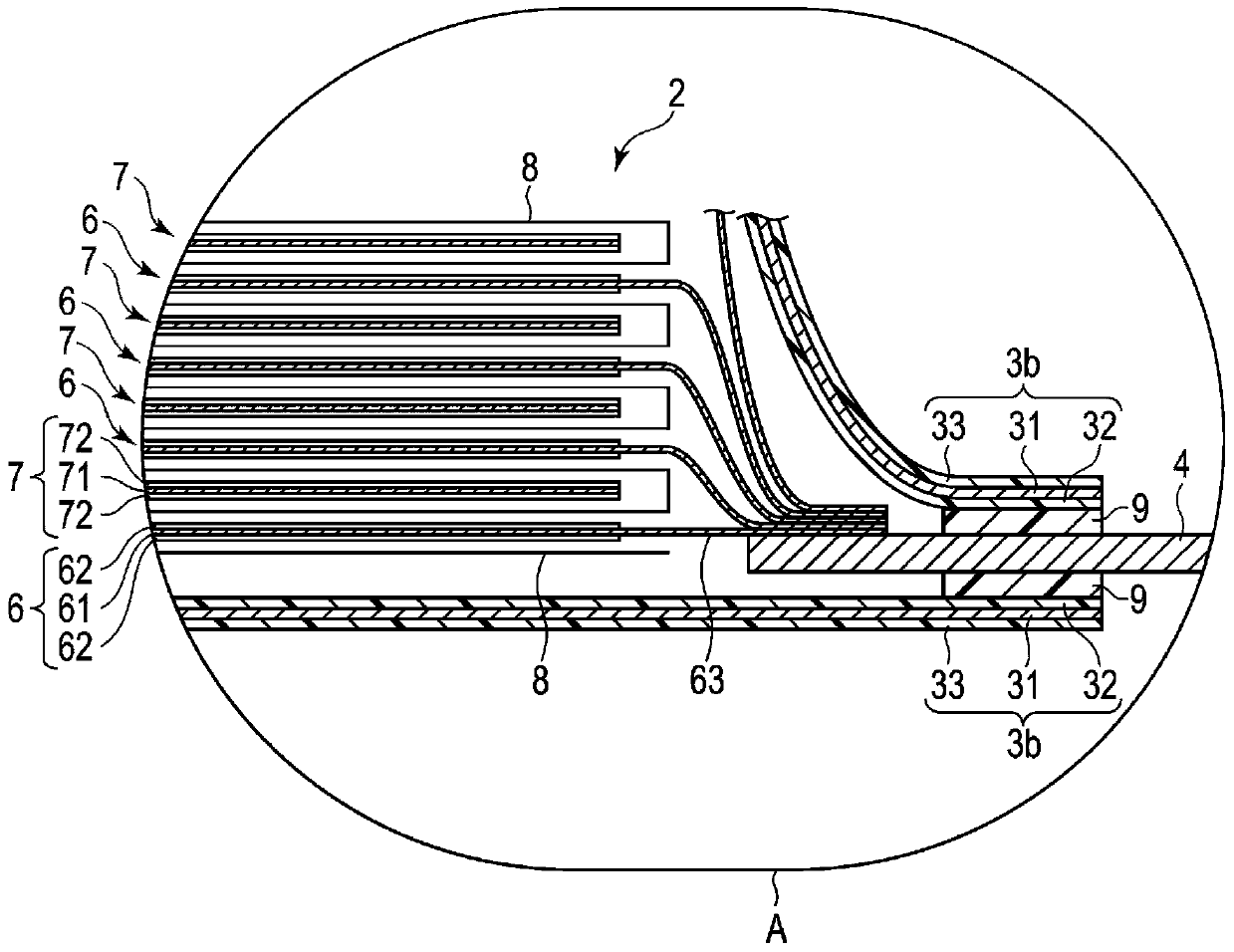

[0156] According to a second embodiment, a battery pack is provided. This battery pack includes the nonaqueous electrolyte battery according to the first embodiment.

[0157] The battery pack according to the second embodiment may further include a plurality of non-aqueous electrolyte batteries. A plurality of nonaqueous electrolyte batteries can be electrically connected in series, or can be electrically connected in parallel. Alternatively, a plurality of non-aqueous electrolyte batteries can also be connected in series and in parallel in combination.

[0158] For example, the battery pack according to the second embodiment may further include five first non-aqueous electrolyte batteries. These nonaqueous electrolyte batteries can be connected in series, for example.

[0159] In addition, the connected non-aqueous electrolyte cells can constitute a battery pack. That is, the battery pack according to the second embodiment may further include assembled batteries.

[0160...

Embodiment 1

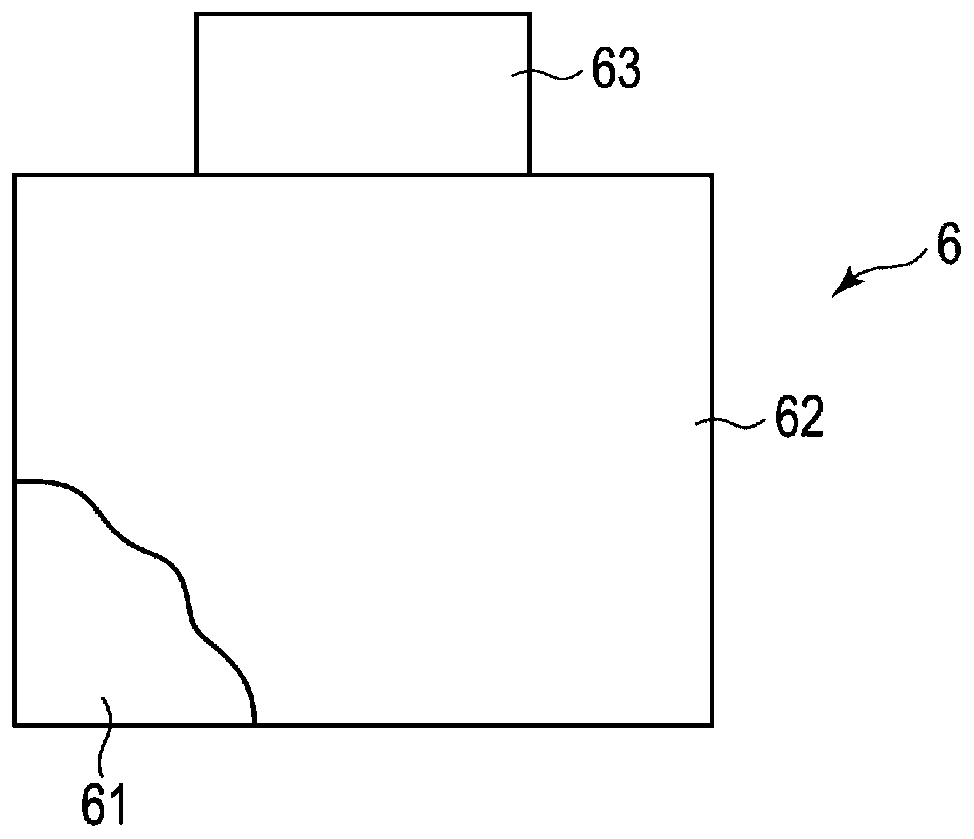

[0180] In Example 1, a nonaqueous electrolyte battery was fabricated through the following procedure.

[0181] [making of positive electrode]

[0182] As the positive electrode active material, a commercially available aluminum-containing lithium-manganese composite oxide (LiAl 0.25 mn 1.75 o 4 ) particles and lithium cobalt oxide (LiCoO 2 )particle of. The aluminum-containing lithium-manganese composite oxide particles are a mixture including primary particles and secondary particles formed by agglomerating the primary particles. The average particle size s of the aluminum-containing lithium-manganese composite oxide particles was 5 μm. In addition, lithium cobaltate particles are primary particles. The average primary particle size t of the lithium cobaltate particles was 8 μm. These were mixed so that the weight ratio of aluminum-containing lithium-manganese composite oxide:lithium cobaltate was 92:8, and it was used as a positive electrode active material.

[0183]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com