Prefabricated steel tube bundle partially-prestressed concrete beam and construction method thereof

A technology of concrete beams and construction methods, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of unfavorable steel pipe bundle composite structure promotion and application, restricted door and window layout, and large installation workload, etc., to achieve reliability and safety, reducing beam deflection, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

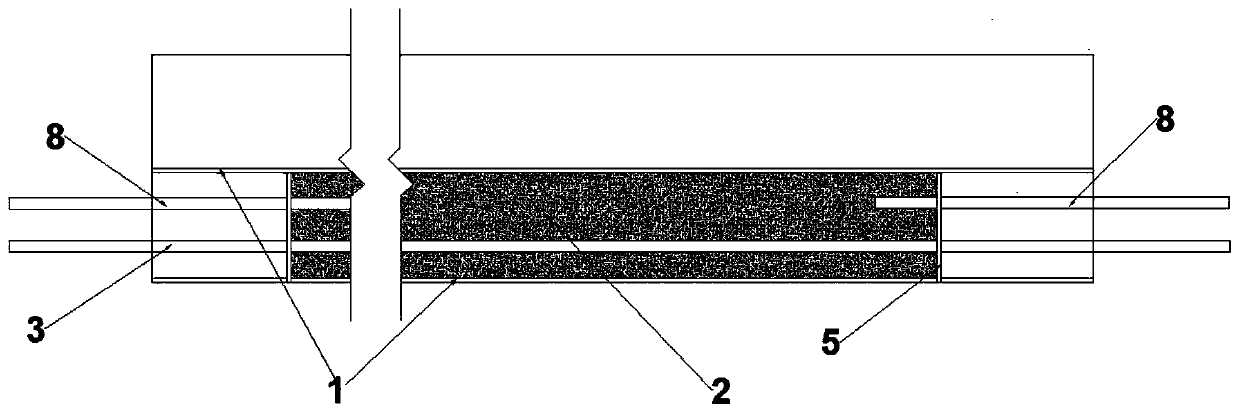

[0053] The hollow lattice steel pipe bundle 1 is welded by 2 steel members to form a straight structure; the baffle plate 5 is symmetrically welded and fixed at both ends of the innermost steel member of the bottom layer, and the other steel member is not provided with the baffle plate 5 ,Such as Figure 1-2 shown;

[0054] Construction method:

[0055] Step 1. Two baffles 5 are symmetrically welded and fixed on both ends of a steel member; the bottom layer of the baffle 5 is provided with 2 prestressed tendon holes 7, and the second layer is provided with 2 reserved holes 6;

[0056] Step 2, insert the prestressed reinforcement 3 in the prestressed reinforcement hole 7 of the baffle plate 5 and run through the whole beam, the prestressed reinforcement 3 and the prestressed reinforcement hole 7 are in clearance fit, and the prestressed reinforcement 3 can be free in the prestressed reinforcement hole 7 Expansion and expansion; After stretching the prestressed steel bar 3 to...

Embodiment 2

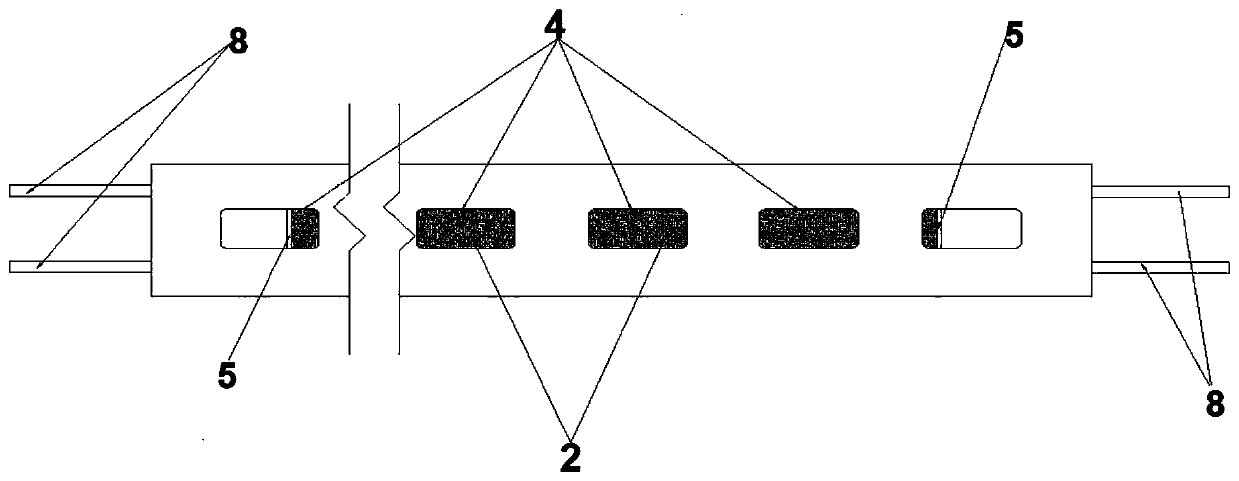

[0060] The hollow lattice steel pipe bundle 1 is welded by 2 steel members to form a straight structure; the baffle plate 5 is symmetrically welded and fixed on both ends of each steel member of the hollow lattice steel pipe bundle 1, and each steel A baffle plate 5 is welded at both ends of the component, such as Figure 3-4 shown;

[0061] Step 1. Weld 2 steel components into a straight hollow lattice steel pipe bundle 1;

[0062] Step 2, welding and fixing four baffles 5 on the two ends of the two-layer steel members of the hollow lattice steel pipe bundle 1; Stress tendon holes 7, the second layer is provided with 2 reserved holes 6; the baffle plate 5 inside a steel member of the second layer is provided with 2 layers, and each layer has 2 reserved holes 6;

[0063] Step 3, insert the prestressed reinforcement 3 in the prestressed reinforcement hole 7 of the baffle plate 5 and run through the whole beam, the prestressed reinforcement 3 and the prestressed reinforcement ...

Embodiment 3

[0066] The hollow lattice steel pipe bundle 1 is welded by 2 steel members to form a straight structure; the baffle plate 5 is symmetrically welded and fixed to the two ends of each steel member of the hollow lattice steel pipe bundle 1, and is adopted in the hollow lattice After all the middle steel plates of the structural steel pipe bundle 1 are provided with through grooves, a baffle plate 5 is welded to each of the two ends of all the steel members inside the hollow lattice steel pipe bundle 1, such as Figure 5 shown;

[0067] Step 1. Weld 2 steel components into a straight hollow lattice steel pipe bundle 1;

[0068] Step 2. After inserting the two baffles 5 into the through grooves on all the middle steel plates respectively, weld and fix the two ends inside the two-layer steel members of the hollow lattice steel pipe bundle 1; The bottom layer of the baffle plate 5 is provided with 2 prestressed tendon holes 7, and the second layer is provided with 2 reserved holes 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com