Weather-resistant wire and cable material and production process thereof

A wire and cable material and weather resistance technology, applied in the field of wire and cable, can solve the problem of lack of weather resistance, and achieve the effect of overcoming poor weather resistance, improving comprehensive performance and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

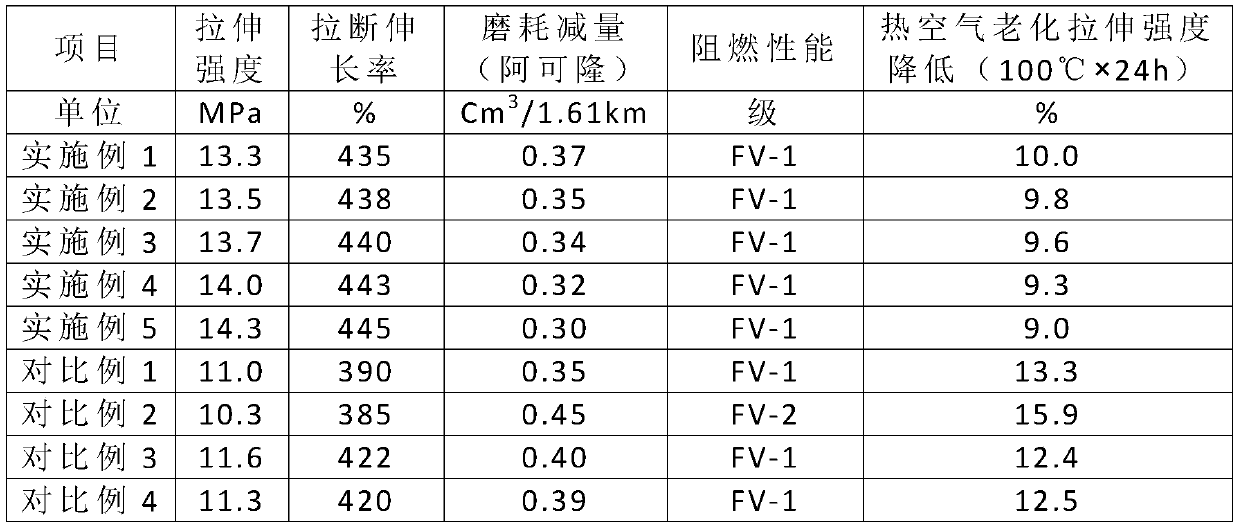

Examples

Embodiment 1

[0030] A weather-resistant wire and cable material, characterized in that it is made of the following raw materials in parts by weight: 70 parts of perfluorotriazine rubber, 15 parts of epichlorohydrin rubber, benzotriazole-1-carboxythioacid allyl amide / 2,4-diamino-6-vinyl-S-triazine / triisopropoxide titanium methacrylate / 4-hydroxybutyl vinyl ether copolymer 20 parts, carbide slag 5 parts, pozzolan 5 parts , 2 parts of epoxy asphalt, 3 parts of dibenzoyl peroxide.

[0031]The benzotriazole-1-carboxythioacid allylamide / 2,4-diamino-6-vinyl-S-triazine / titanium methacrylate triisopropoxide / 4-hydroxybutylethylene The preparation method of base ether copolymer comprises the steps of: benzotriazole-1-carboxythioacid allylamide, 2,4-diamino-6-vinyl-S-triazine, methacrylic acid three Titanium isopropoxide, 4-hydroxybutyl vinyl ether, and benzoyl peroxide were added to N,N-dimethylformamide, stirred and reacted at 70°C for 4 hours in a nitrogen atmosphere, and then precipitated in water...

Embodiment 2

[0036] A weather-resistant wire and cable material, characterized in that it is made of the following raw materials in parts by weight: 72 parts of perfluorotriazine rubber, 17 parts of epichlorohydrin rubber, benzotriazole-1-carboxythioacid allyl amide / 2,4-diamino-6-vinyl-S-triazine / triisopropoxide titanium methacrylate / 4-hydroxybutyl vinyl ether copolymer 23 parts, gas slag 6 parts, pozzolan ash 6 parts , 3 parts of epoxy pitch, 4 parts of tetramethylthiuram disulfide.

[0037] The benzotriazole-1-carboxythioacid allylamide / 2,4-diamino-6-vinyl-S-triazine / titanium methacrylate triisopropoxide / 4-hydroxybutylethylene The preparation method of base ether copolymer comprises the steps of: benzotriazole-1-carboxythioacid allylamide, 2,4-diamino-6-vinyl-S-triazine, methacrylic acid three Titanium isopropoxide, 4-hydroxybutyl vinyl ether, and tert-butyl hydroperoxide were added to N,N-dimethylacetamide, stirred and reacted at 73°C for 4.5 hours in a helium atmosphere, and then prec...

Embodiment 3

[0042] A weather-resistant wire and cable material, characterized in that it is made of the following raw materials in parts by weight: 75 parts of perfluorotriazine rubber, 20 parts of epichlorohydrin rubber, benzotriazole-1-carboxythioacid allyl amide / 2,4-diamino-6-vinyl-S-triazine / triisopropoxide titanium methacrylate / 4-hydroxybutyl vinyl ether copolymer 25 parts, boron slag 8 parts, pozzolan ash 7 parts , 3.5 parts of epoxy pitch, 4.5 parts of zinc dibutyldithiocarbamate.

[0043] The benzotriazole-1-carboxythioacid allylamide / 2,4-diamino-6-vinyl-S-triazine / titanium methacrylate triisopropoxide / 4-hydroxybutylethylene The preparation method of base ether copolymer comprises the steps of: benzotriazole-1-carboxythioacid allylamide, 2,4-diamino-6-vinyl-S-triazine, methacrylic acid three Titanium isopropoxide, 4-hydroxybutyl vinyl ether, and azobisisobutyronitrile were added to N-methylpyrrolidone, stirred and reacted at 78°C for 5.5 hours in a neon atmosphere, and then preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com