Pressure swing adsorption purification and recovery device and process for polypropylene SPG process tail gas

A pressure swing adsorption, process tail gas technology, applied in gas treatment, specific gas purification/separation, inorganic chemistry, etc., to achieve the effect of simple operation, strong operational adaptability, and elimination of human interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

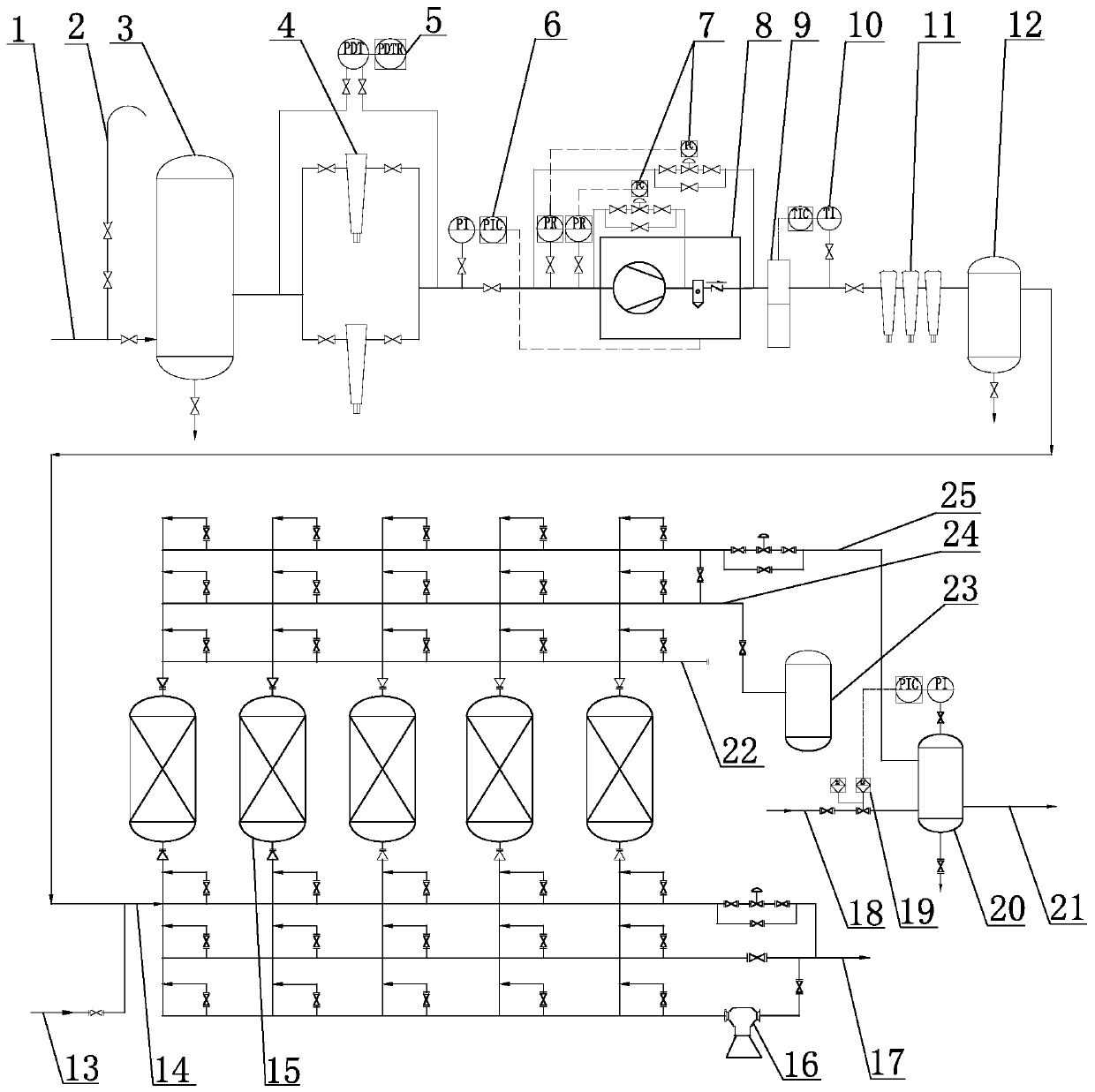

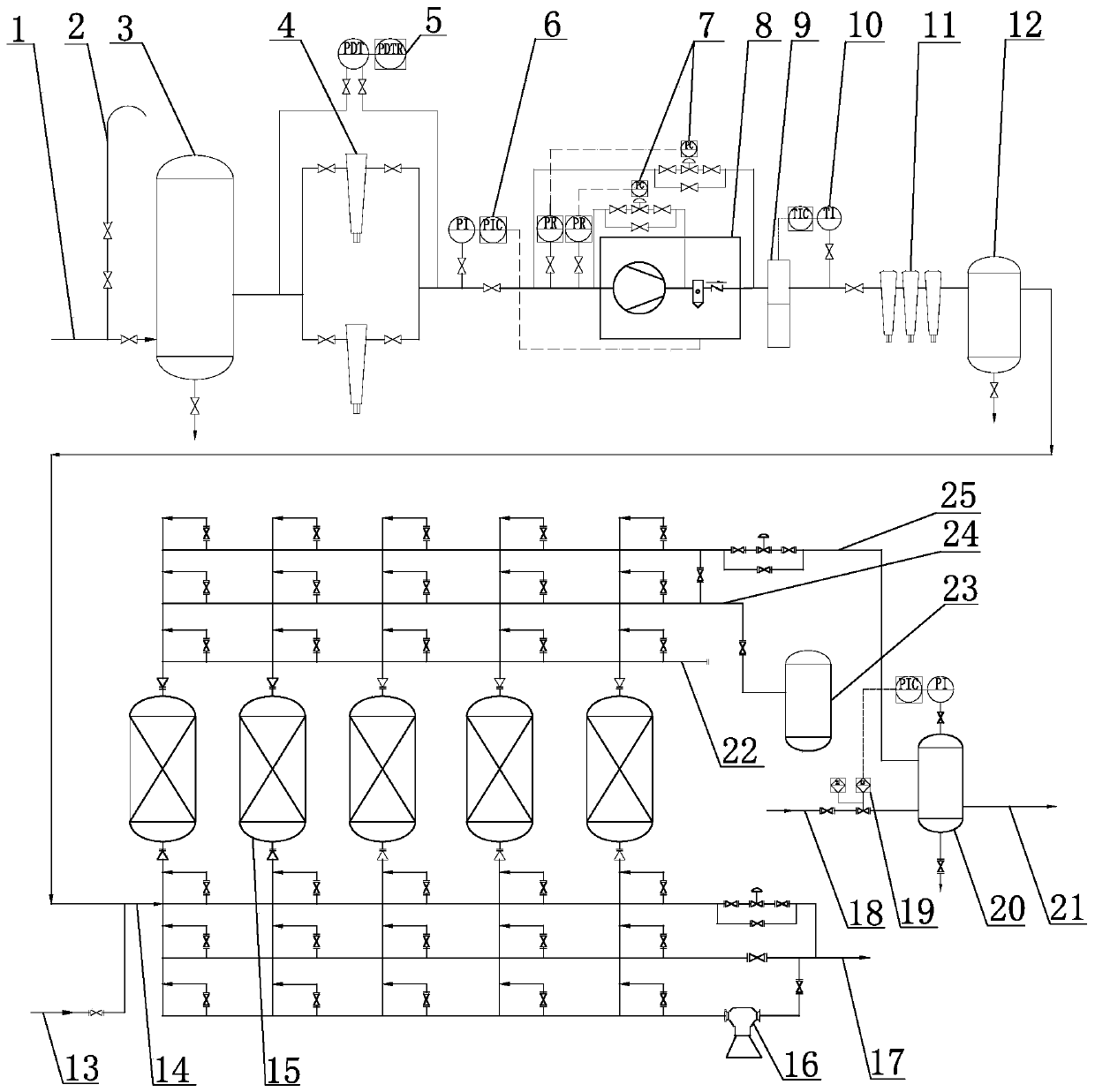

[0045] Such as figure 1As shown, a pressure swing adsorption purification and recovery device for polypropylene SPG process tail gas of the present invention includes a recovery gas buffer tank 3, a folded wave filter 4, a compressor 8, a cold dryer 9, and three-stage precision filtration successively connected device 11, separator 12 and pressure swing adsorption tower 15; the recovery gas buffer tank 3 is connected with polypropylene SPG process tail gas pipeline 1; the top of the pressure swing adsorption tower 15 is connected to the nitrogen buffer tank 20 through a nitrogen discharge pipeline 25 , the nitrogen buffer tank 20 is connected with a nitrogen recycling pipeline 21; the top of the pressure swing adsorption tower 15 is also connected with the flushing gas buffer tank 23 through a parallel release pipeline 24; the bottom of the pressure swing adsorption tower 14 is connected with an inlet pipeline 14 and a Drain line 17.

[0046] The polypropylene SPG tail gas pi...

Embodiment 2

[0058] The pressure swing adsorption purification and recovery device of the polypropylene SPG process tail gas of Example 1 is used to treat the tail gas of the 300,000 tons / year SPG process polypropylene enterprise, the tail gas temperature is 35 ° C, the pressure is 1.5KPa (g), and the flow rate is 1500Nm 3 / h (dry gas), in mol percentage, tail gas component analysis is as follows:

[0059] name Acrylic propane Nitrogen n-butane ethane water vapor C6+ Isopentane Content, %mol 2.46 1.044 96.457 0.001 0.034 saturation 0.02 0.001

[0060] The specific process steps are as follows:

[0061] After the tail gas of the polypropylene SPG process is stabilized by the recovery gas buffer tank 3, it is filtered through the folding filter 4 in turn, pressurized to 0.5-0.8 MPa through the compressor 8 (adjusted according to the pressure requirements of nitrogen reuse), and then passed through the cold The drying machine 9 performs cooling and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com