Composite industrial oil fume purifier and oil fume purification system

A kind of oil fume purifier and composite technology, which is applied in the direction of chemical instruments and methods, combined devices, and dispersed particle separation, etc., can solve the problems such as troublesome cleaning of filter screens, achieve improved ventilation, purification and filtration effects, convenient operation, and good exhaust effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] refer to figure 1 , this embodiment discloses a composite industrial fume purifier, comprising a box 1, the box 1 is provided with an air inlet 11 and an air outlet 12, the bottom of the box 1 is provided with an oil collection tank 14, and the oil collection tank 14 is the upper The bottom of the oil collection tank 14 is provided with an oil discharge pipe 15, the oil discharge pipe 15 is provided with an oil discharge valve 16, and the bottom of the box body 1 is provided with a support foot 13; the inner cavity of the box body 1, from the air inlet From 11 to the air outlet 12, a flow equalizing section 2, a filter screen 4 and an electric field section are provided in sequence; a first nozzle assembly is arranged between the filter screen 4 and the electric field section, and the first nozzle assembly is arranged above the box body 1 and faces the filter screen 4 settings.

[0031] Wherein, the flow sharing section 2 is a cellular flow sharing network. The filter...

Embodiment 2

[0035] refer to figure 2 , on the basis of Embodiment 1, the box 1 is provided with a second spray head assembly, the second spray head assembly is arranged between the flow equalization section 2 and the filter screen 4, and the second spray head assembly includes a second quick connector 321, The second water pipe 322 and the second several nozzles; the upper end of the second water pipe 322 links to each other with the second quick connector 321, and the lower end of the second water pipe 322 links to each other with several second nozzles 323, and the spraying range of several second nozzles 323 Covering the entire flow equalizing section 2 ; the second quick connector 321 is arranged above the box body 1 . Setting the second spray head assembly can clean the entire flow equalization section 2; using the second quick connector 321, it can be quickly connected to the external water pipe connector.

[0036] refer to figure 2, the top of the box body 1 is provided with a ...

Embodiment 3

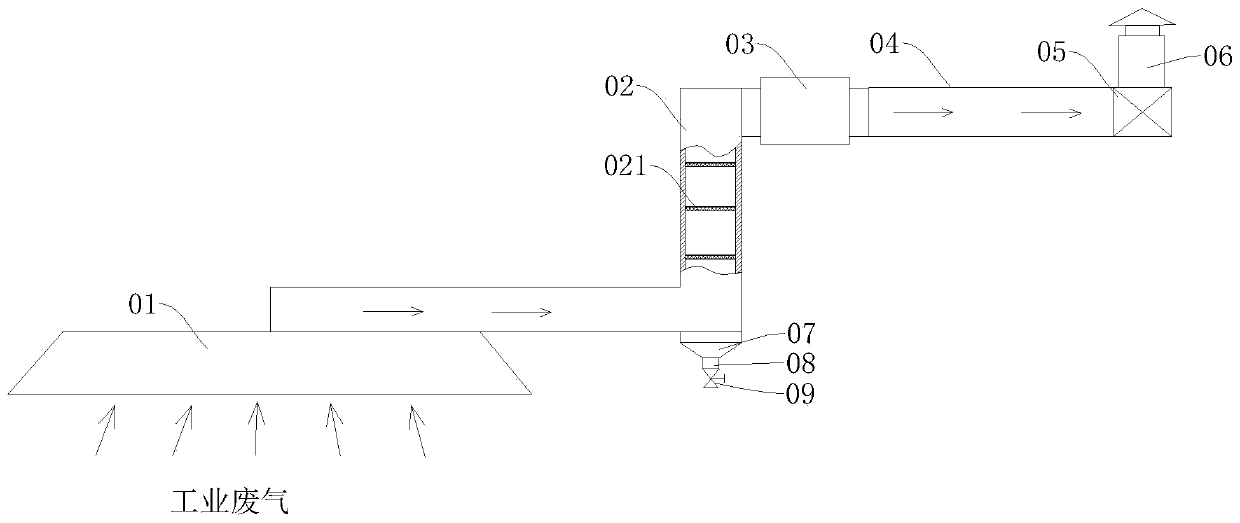

[0039] refer to image 3 , the present embodiment discloses an oil fume purification system, comprising a fume collecting hood 01, a composite industrial oil fume purifier 03, a fan 05 and a muffler 06 sequentially connected through an oil fume passage.

[0040] The composite industrial oil fume purifier 03 in this embodiment, such as figure 2 As shown, the box body 1 is included, the box body 1 is provided with an air inlet 11 and an air outlet 12, the bottom of the box body 1 is provided with an oil sump 14, and the oil sump 14 is a tapered groove with a large upper part and a smaller lower part. There is an oil discharge pipe 15 at the bottom, an oil discharge valve 16 is provided on the oil discharge pipe 15, and a support foot 13 is provided under the box body 1; the inner cavity of the box body 1 is provided with a flow equalization section 2 in turn from the air inlet 11 to the air outlet 12 , the filter screen 4 and the electric field segment; a first spray head asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com