Exhausting structure of thin-wall injection molding die

An injection molding and mold technology, which is applied to the exhaust structure of the mold and the exhaust structure of the thin-walled injection molding mold, can solve the problems of poor strength and shorten the service life of the mold, so as to ensure product quality, reduce the molding cycle, and solve the problem of Difficulty filling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

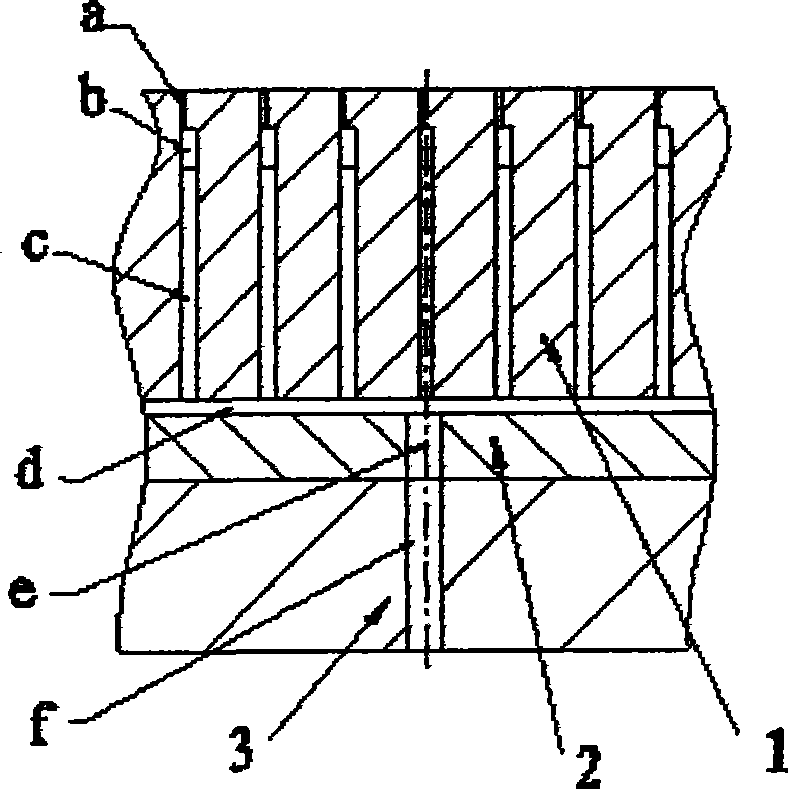

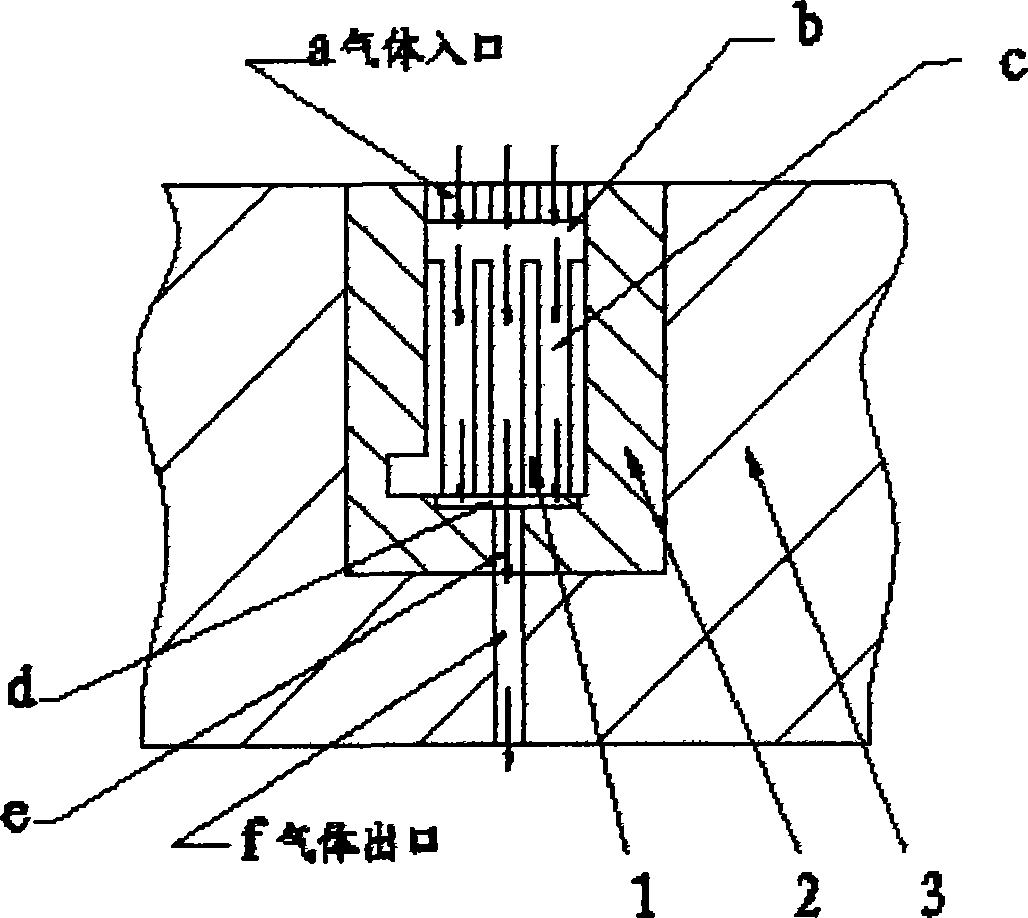

[0010] Preferred embodiment of the present invention, see appendix figure 1 Sectional drawing of the exhaust structure, attached figure 2 A preferred solution for opening exhaust grooves and exhaust slits on the side of the exhaust sheet.

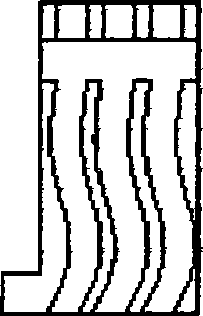

[0011] An exhaust structure for a thin-walled injection molding mold, which is composed of a set of exhaust pieces 1, a base 2 and a mold cavity plate 3. The structure has the following characteristics: a set of exhaust pieces 1 into the base 2 in turn, and then put the assembly into the mold cavity plate 3, the base 2 and the mold cavity plate 3 are connected by screws, and the side of the exhaust piece 1 is provided with a horizontal The exhaust groove b and the longitudinal exhaust groove c are connected to form a T-shaped groove, and a plurality of shallow longitudinal exhaust slits a communicating with it are designed on the upper end of the horizontal exhaust groove b of the exhaust sheet 1. When exhausting, the type The gas in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com