Embossed paper as well as preparation method and application thereof

A technology of embossed paper and embossed layer, applied in the field of composite paper, can solve problems such as poor strength, damage, bulging, etc., and achieve the effects of improving mechanical properties, transparency, and good exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

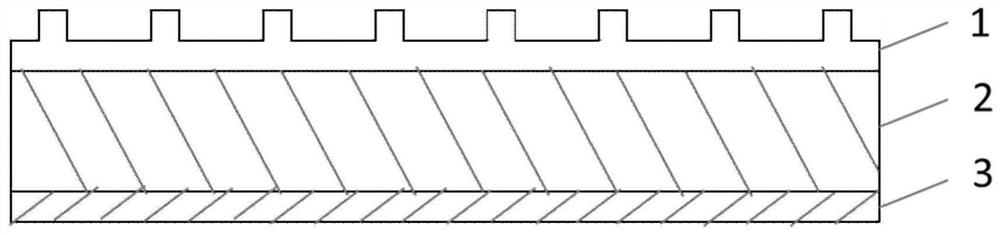

[0084] This embodiment provides a kind of embossed paper, wherein each layer parameter is as follows:

[0085] composition parameter Resin embossed layer Thickness 30μm paper layer Thickness 100μm resin layer 25μm Depth of air guide groove 15μm The width of the raised part of the air guide groove 0.15mm Air groove width 0.55mm Air groove shape diamond Cross-sectional shape of the air guide groove "V" shape

[0086] The preparation method is as follows:

[0087] (1) 50 parts of low-density polyethylene resin, 25 parts of high-density polyethylene resin and 25 parts of homopolypropylene resin are mixed, and melted in a hopper at 280 ° C to obtain the melted resin;

[0088] (2) Coat the melted resin obtained in step (1) on one side of the kraft paper layer, and cold press at 0.7MPa through an embossing cylinder for 1.2s to obtain a resin embossed layer;

[0089] (3) After mixing 50 parts of low-density polye...

Embodiment 2

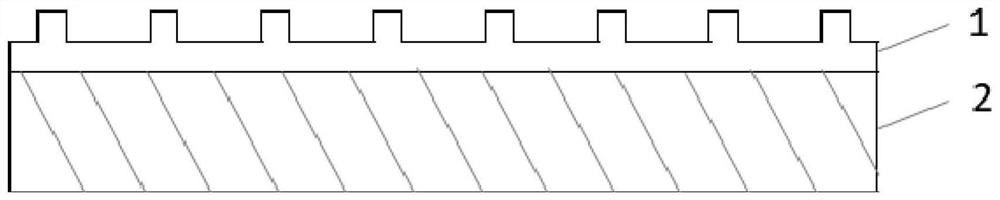

[0093] This embodiment provides a kind of embossed paper, wherein each layer parameter is as follows:

[0094] composition parameter Resin embossed layer Thickness 20μm paper layer Thickness 50μm resin layer 12μm Depth of air guide groove 5μm The width of the raised part of the air guide groove 0.1mm Air groove width 0.45mm Air groove shape rectangle Cross-sectional shape of the air guide groove "V" shape

[0095] The preparation method is as follows:

[0096] (1) Mix 37.5 parts of low-density polyethylene resin, 12.5 parts of high-density polyethylene resin and 50 parts of copolymerized polypropylene resin, and melt them in a hopper at 200 ° C to obtain the melted resin;

[0097] (2) Coat the melted resin obtained in step (1) on one side of the glassine paper layer, and cold press at 0.4 MPa through an embossing cylinder for 1.5 seconds to obtain a resin embossed layer;

[0098] (3) After mixing 37.5 par...

Embodiment 3

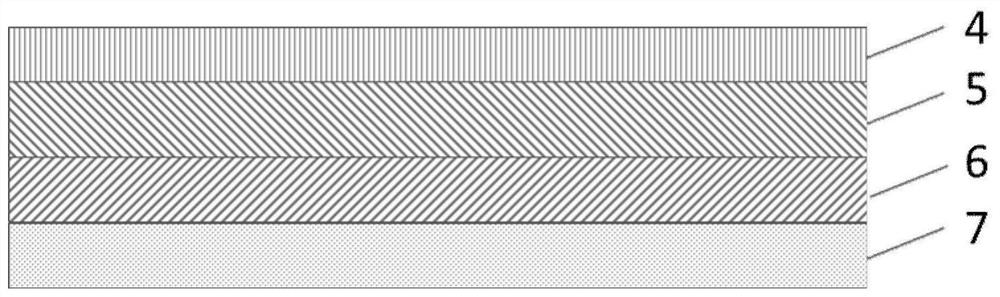

[0102] This embodiment provides a kind of embossed paper, wherein each layer parameter is as follows:

[0103] composition parameter Resin embossed layer Thickness 40μm paper layer Thickness 150μm resin layer 30μm Depth of air guide groove 40μm The width of the raised part of the air guide groove 0.25mm Air groove width 2.4mm Air groove shape hexagon Cross-sectional shape of the air guide groove "︺"shape

[0104] The preparation method is as follows:

[0105] (1) Mix 60 parts of low-density polyethylene resin and 40 parts of high-density polyethylene resin, melt them in a hopper at 350° C., and obtain the melted resin;

[0106](2) Coating the melted resin obtained in step (1) on one side of the coated paper layer, cold pressing at 1.0 MPa through an embossing cylinder, and cold pressing for 0.4s to obtain a resin embossed layer;

[0107] (3) After mixing 60 parts of low-density polyethylene resin and 20 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com