Exhaust structure of double-color mold

A two-color mold and exhaust surface technology, applied in the field of exhaust structure, can solve problems such as poor exhaust, product needle lines and black joints, affecting product production yield, etc., to improve soft rubber air trapping, exhaust Good effect and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

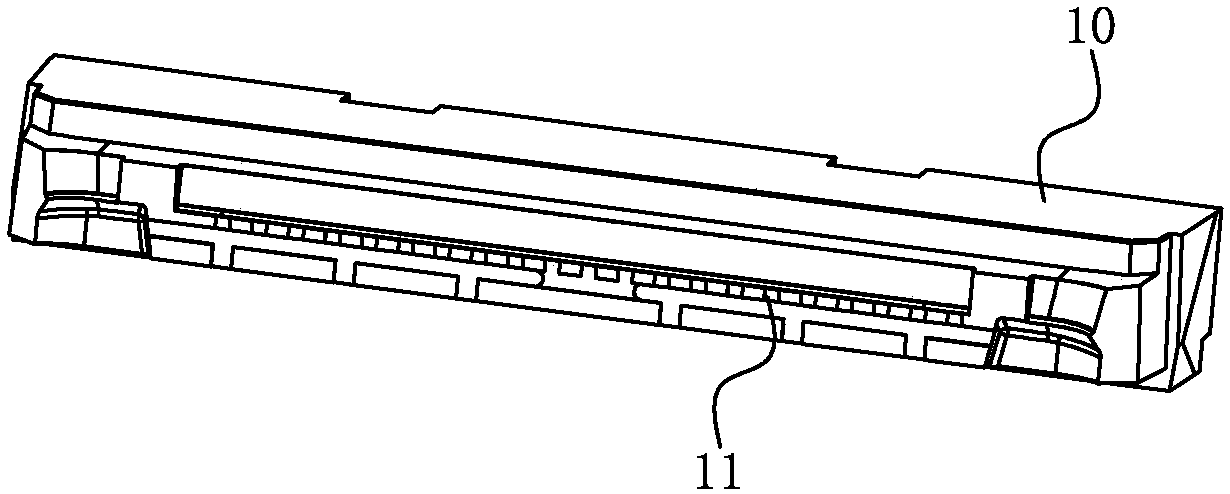

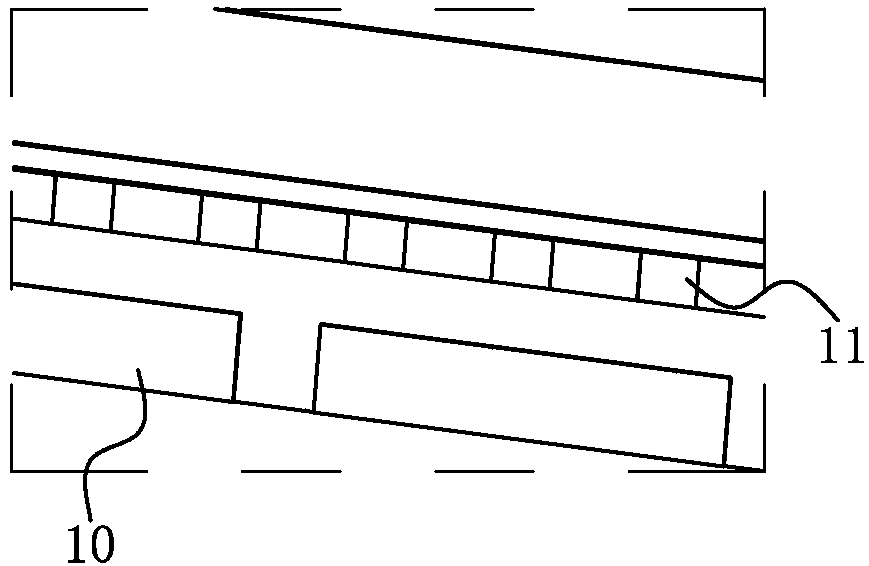

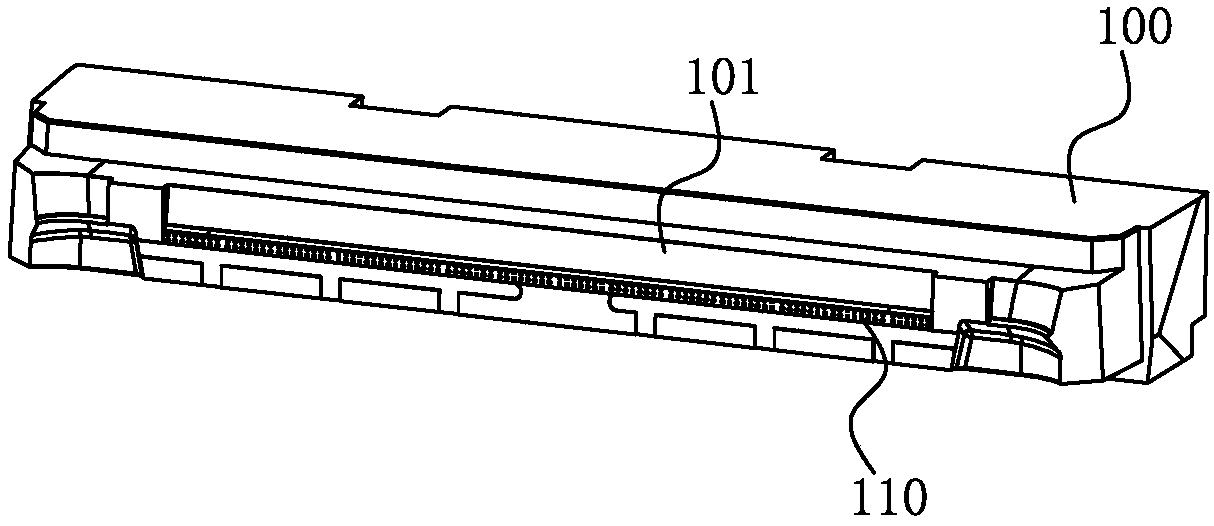

[0017] see image 3 and Figure 4 shown, where image 3 A schematic diagram of the exhaust structure of the two-color mold of the present invention is shown, Figure 4 painted image 3 A partial enlargement of the .

[0018] In this embodiment, the exhaust structure of the two-color mold of the present invention is arranged on the slider 100 of the two-color mold. The exhaust structure has an exhaust surface 110, and the exhaust surface 110 is arranged on the side of the soft rubber position 101. At the broken part, the soft rubber position 101 is the position where the soft rubber is formed. The entire surface of the exhaust surface 110 is treated by embossing. After the embossing treatment, the exhaust surface 110 has concave and convex lines 111. The gas in the mold is discharged from the concave-convex lines 111 . Wherein, the embossing treatment refers to the use of chemicals to corrode the surface of the exhaust surface 110 to form concave and convex lines 111 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com