Residential composite exhaust passage and mounting method thereof

An installation method and exhaust duct technology, which are applied in vertical pipes, building components, buildings, etc., can solve the problems of easy deformation, distortion, poor sealing effect, and deep bending, and achieve good sealing performance, easy installation, and strength. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

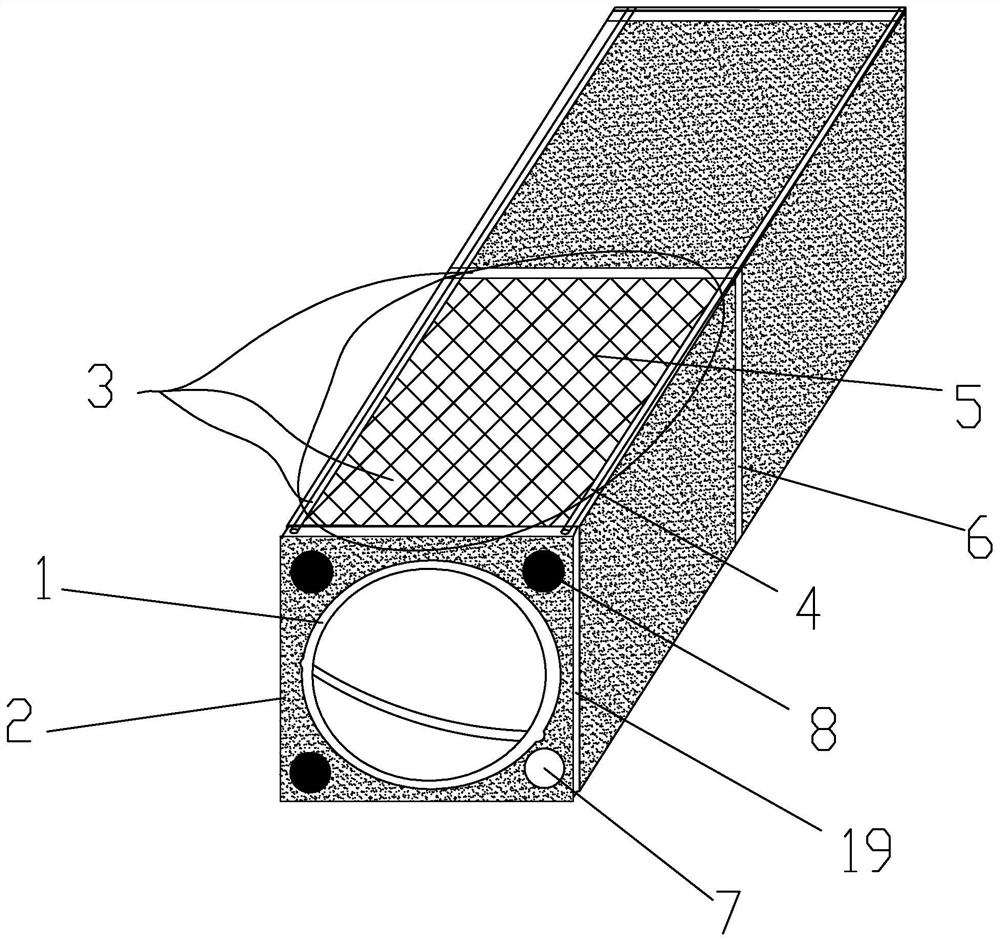

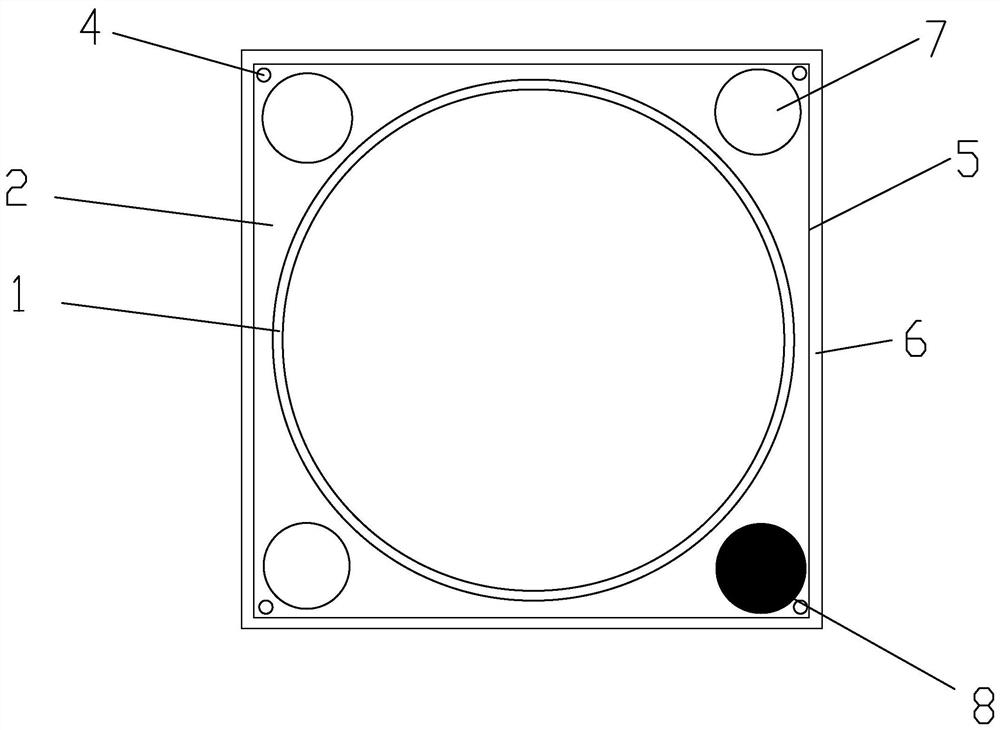

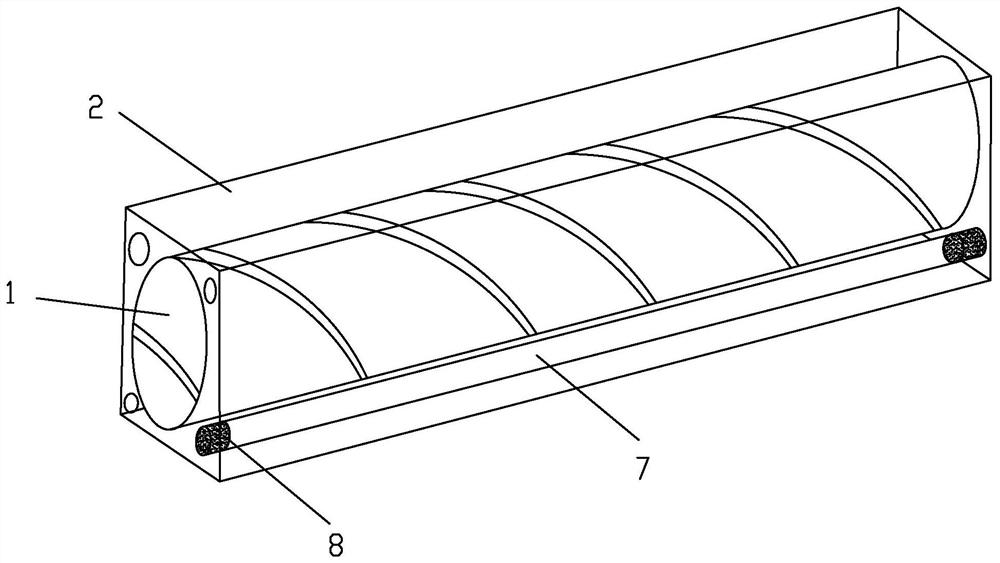

[0045] exist figure 1 , figure 2 In the illustrated embodiment, a residential compound exhaust duct includes:

[0046] The inner exhaust channel 1 is used for the internal passage of oil fume gas. The inner exhaust channel 1 is a metal pipe; the inner exhaust channel 1 is a stainless steel spiral pipe body; the inner exhaust channel 1 is circular airway;

[0047] The outer exhaust duct 2 is arranged outside the inner exhaust duct 1 to fix and form the outer cladding of the composite exhaust duct. The outer exhaust duct 2 is a lightweight concrete pipe; the outer exhaust duct 2 is a lightweight concrete pipe. Concrete pouring square pipe body; the two ends of the outer exhaust duct 2 are provided with diameter-reducing structures 19; also include,

[0048] Reinforcement 3, a member arranged on the outer exhaust duct 2 to strengthen the strength and integrity of the inner exhaust duct 1 and the outer exhaust duct 2;

[0049] Wherein, the outer exhaust duct 2 is integrally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com