Method and apparatus for flattening, compacting and crushing material

A flat pressing and material technology, applied in the direction of grain processing, etc., can solve the difficult problems of exhaust compaction effect, scraper wear and other problems, and achieve the effect of good exhaust effect, small wear amount and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

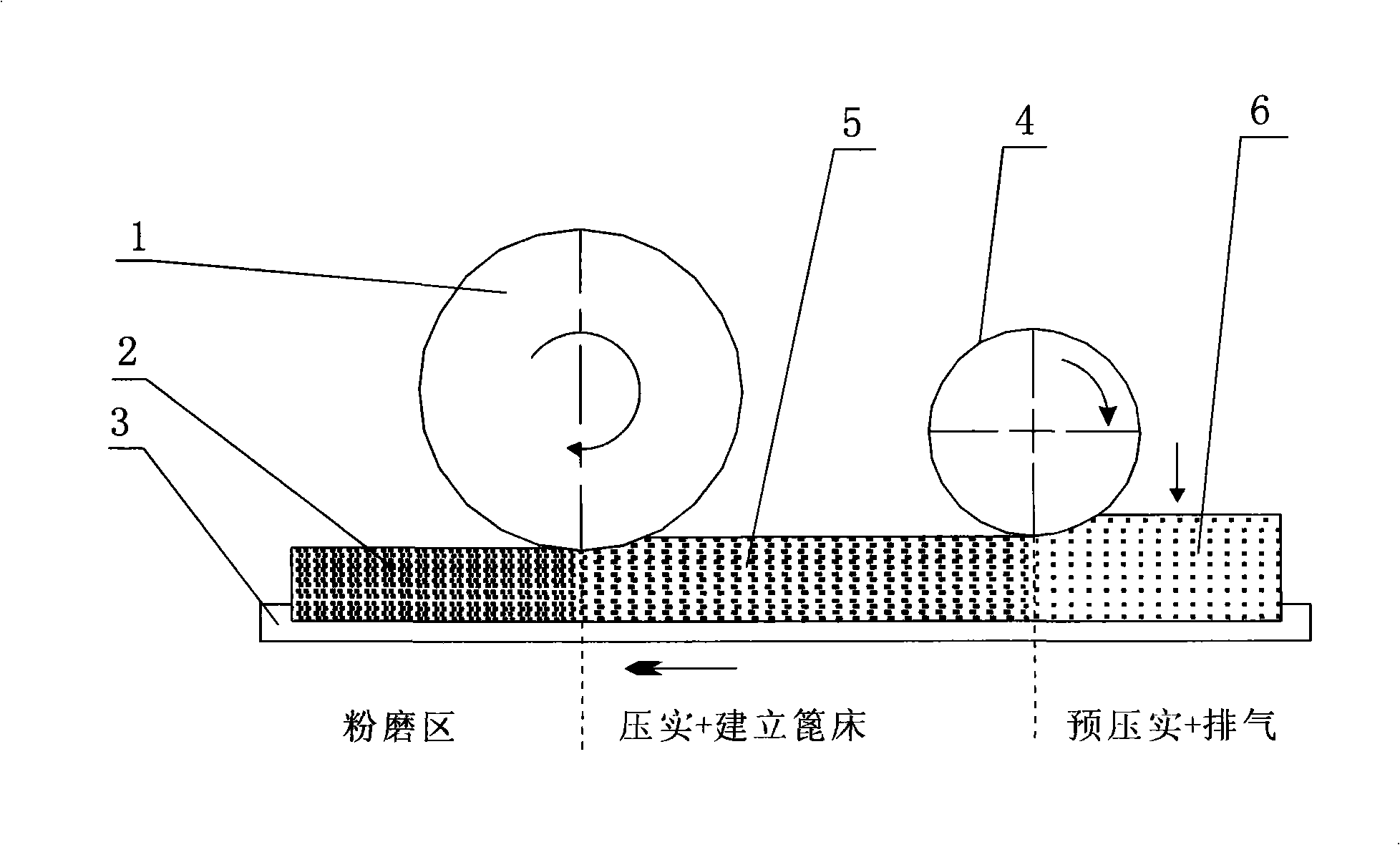

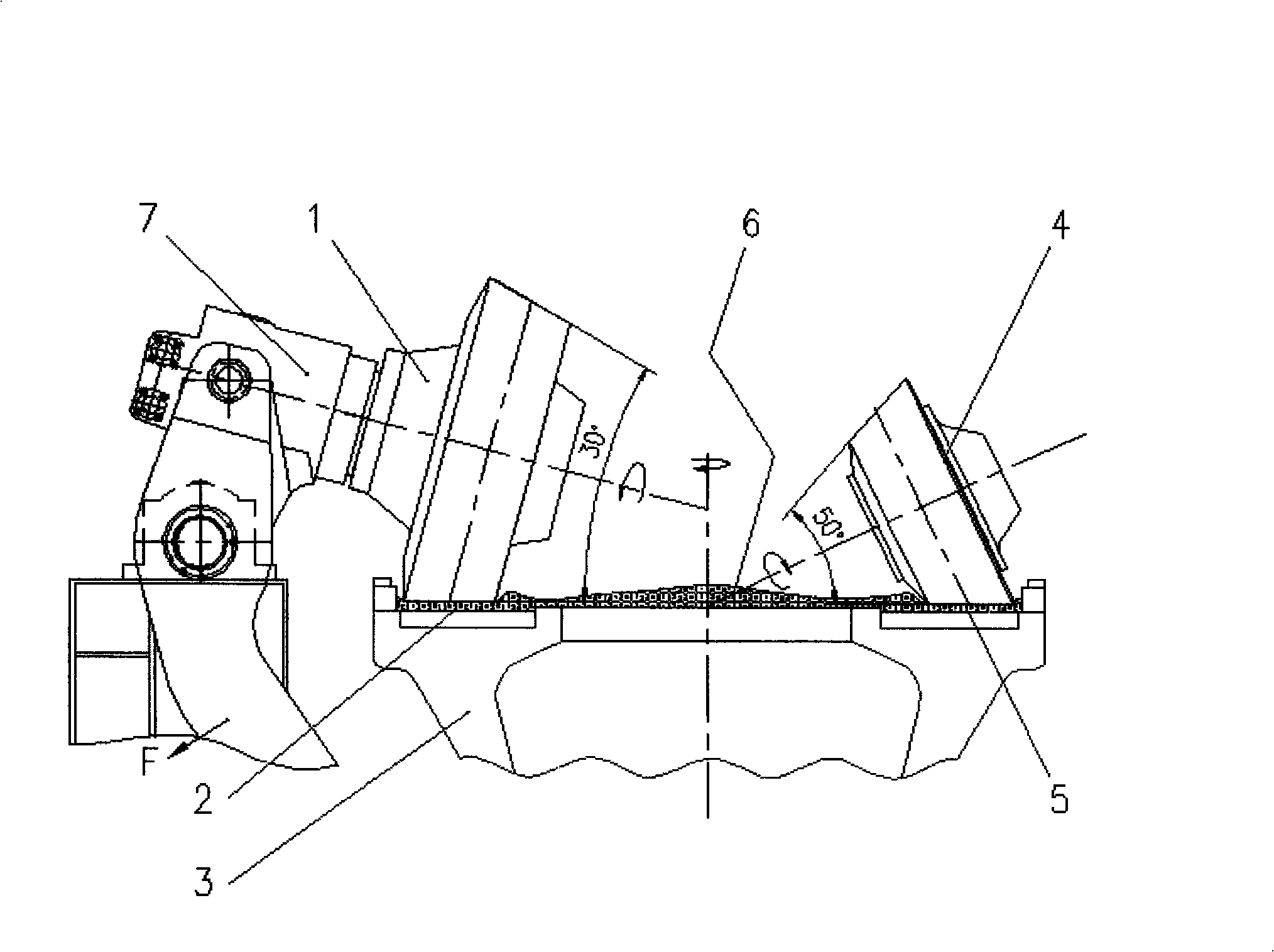

[0016] Such as figure 1 Shown: the method for flattening, compacting and pulverizing the materials to be ground according to the present invention, the method is to place the original accumulated material layer continuously on the grinding disc rotating according to the axis, and carry out the process by passive flattening and compacting rollers. Pre-flattening and compacting, exhausting, flattening and compacting rollers have a certain large cone angle, because the rotational speed of each point on the grinding table is proportional to the radius from each point to the center, this large cone angle can make the grinding roller surface The linear velocity of the point in contact with the grinding disc is close to the same as that of the grinding disc, which is close to the state of pure rolling friction, and using its own weight, the uneven material layer is flattened and compacted under its action; flattened and compacted material With the rotation of the grinding disc, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com