A design method for the slow-wave structure of a stripped injection traveling-wave tube working in high-order modes

A technology of slow-wave structure and high-order mode, applied in the fields of microwave electronics and terahertz, can solve the problems of limiting power capacity and reducing the width of the electronic channel of the strip injection traveling wave tube, so as to increase the power capacity, increase the practicability, and achieve high industrial efficiency. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is further explained below in conjunction with the accompanying drawings:

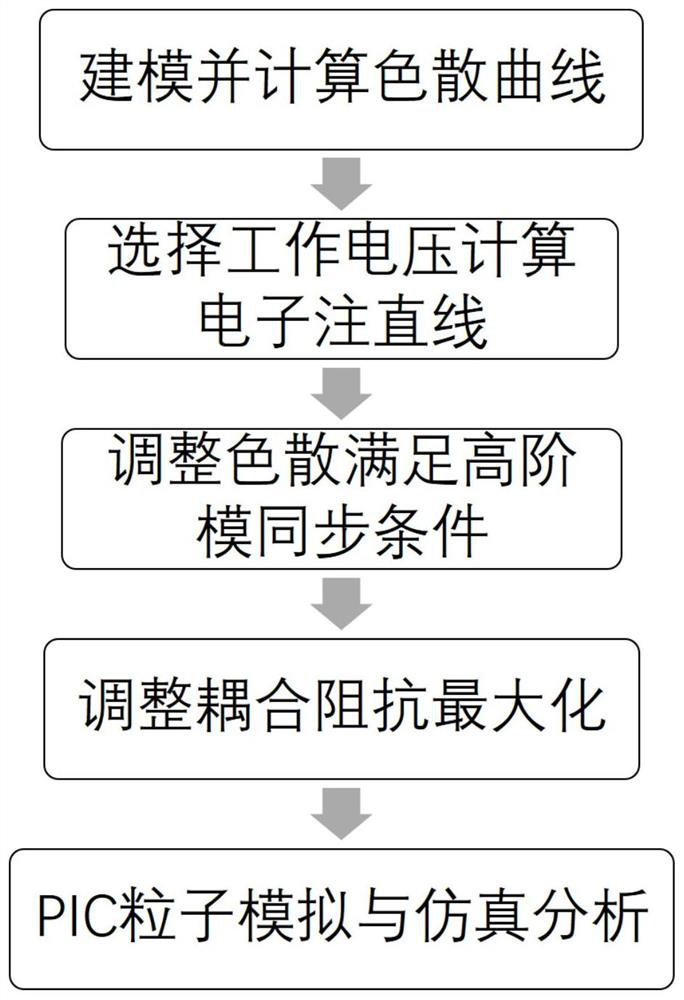

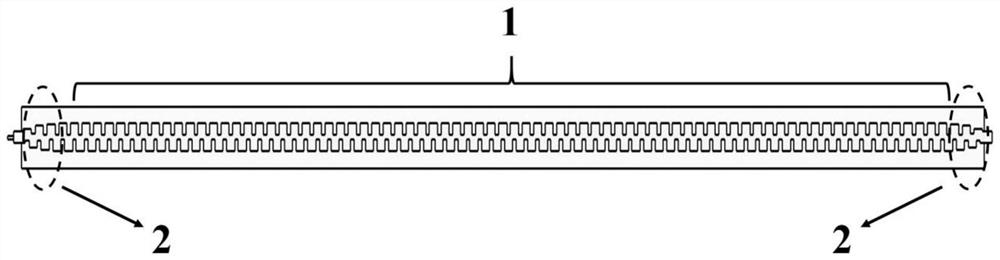

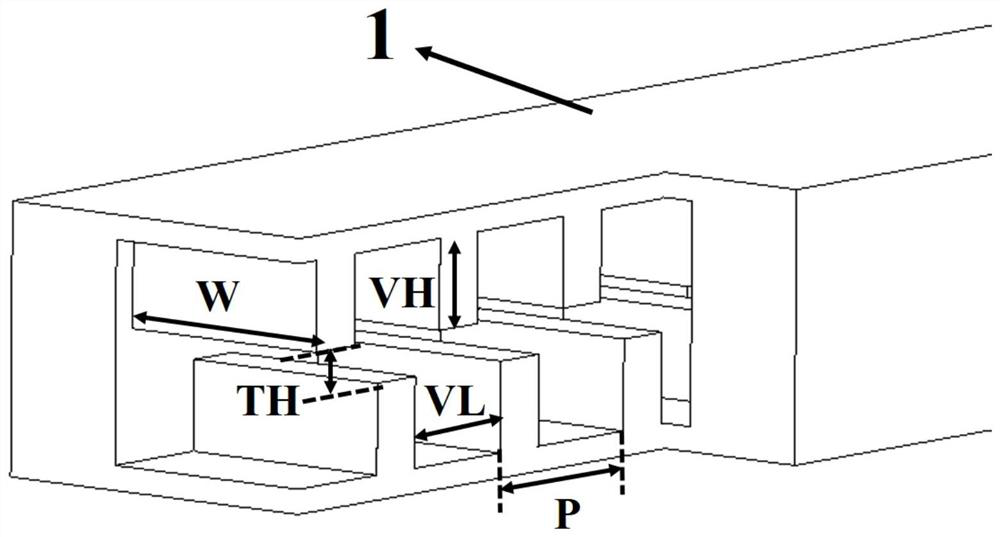

[0028] Refer to the attachment figure 1 The design method of a strip-shaped injection wave tube slow wave structure of the present embodiment includes the following steps: 770 μm from the width W and the electronic channel height th. of its slow wave structure cross section of 770 μm respectively. 150μm. The cycle length of the slow wave structure is 468 μm, the same side two adjacent gate spacing VLs are 351 μm, the gate height VH is 320 μm), and the Software HFSS is modeled and the color scatter is calculated. On this basis, modification is made to the electronic channel, the interlaced gate width, and the height parameters are guaranteed to have the maximum electronic note width while satisfying the required bandwidth on the operating frequency band. At this time, the width w and electronic channel height TH adjustable in the adjusted slow wave structure. It is 900 μm and 150 μm, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com