High-density optical fiber distribution tray

A fiber optic distribution, high-density technology, applied in the field of high-density fiber optic distribution trays, can solve the problem of inconvenient installation and maintenance of distribution optical cables or connecting optical cables, distribution trays cannot be flexibly disassembled from the distribution box, and optical fiber distribution The box space utilization rate is low and other problems, to achieve the effect of compact structure, low duty ratio, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

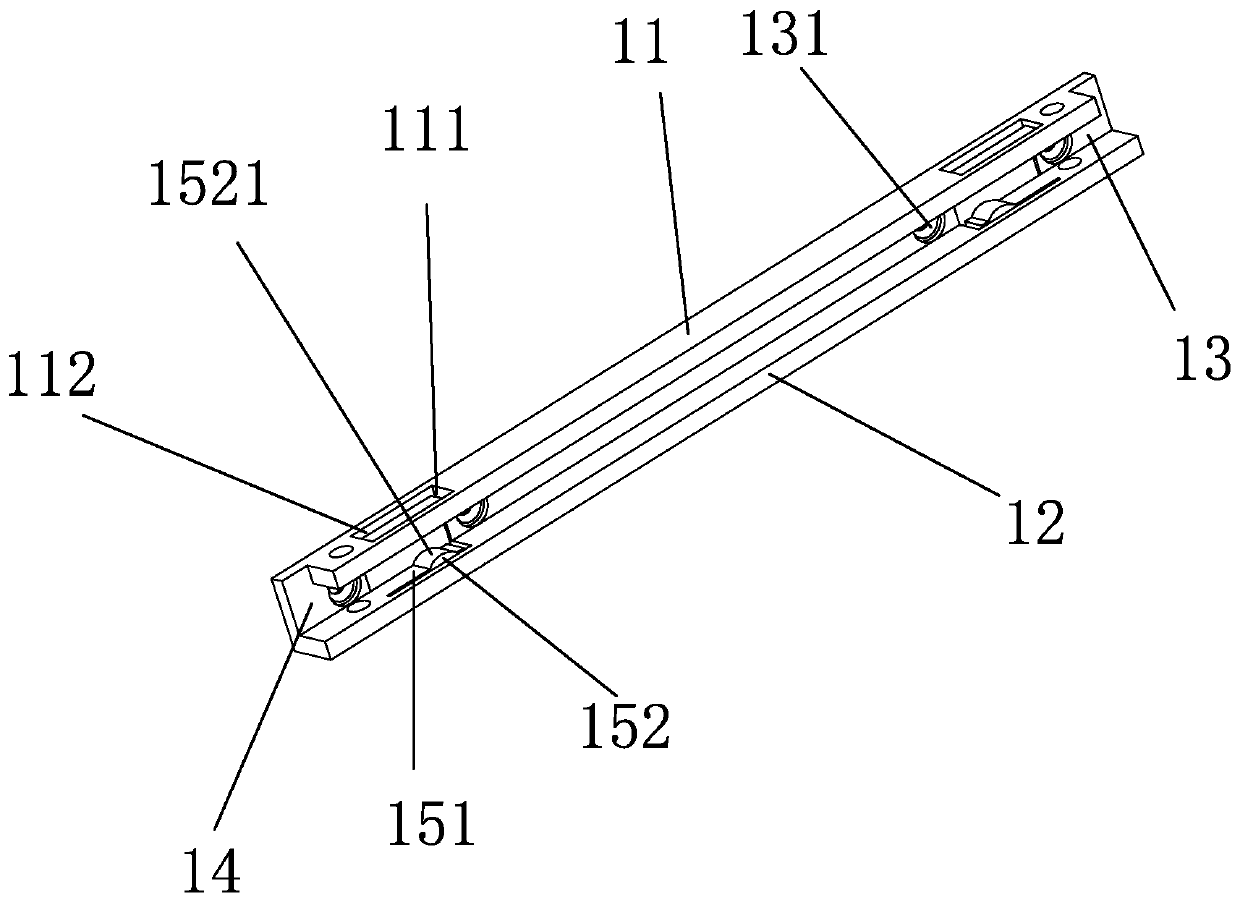

[0031] refer to Figure 1 to Figure 6 , the present invention is realized in this way: the high-density optical fiber distribution tray includes a slide rail 1, a tray body 2 capable of realizing various module conversions between input and output, and the tray body 2 is limited in the slide rail 1 and can be placed on the slide rail 1. Inside the rail 1, the disc body 2 is provided with a wiring area 3, a terminal area 4, a detachable cover body 5 that is clamped with the wiring area 3, and the wiring area 3 is provided with an input installation area 31, an output end The installation area 32 , the fiber storage area 33 arranged between the input end installation area 31 and the output end installation area 32 , the terminal area 4 is set on the side of the output end installation area 32 . The thickness of the disc body 2 is set to be just enough to accommodate an adapter inside, and the thickness of the disc body 2 in the present invention is set to 1.2CM.

[0032] The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com