Galvanic corrosion simulation test device and method for composite steel bar coating and core material

A composite steel bar, galvanic corrosion technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, analysis materials, etc. , easy operation and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

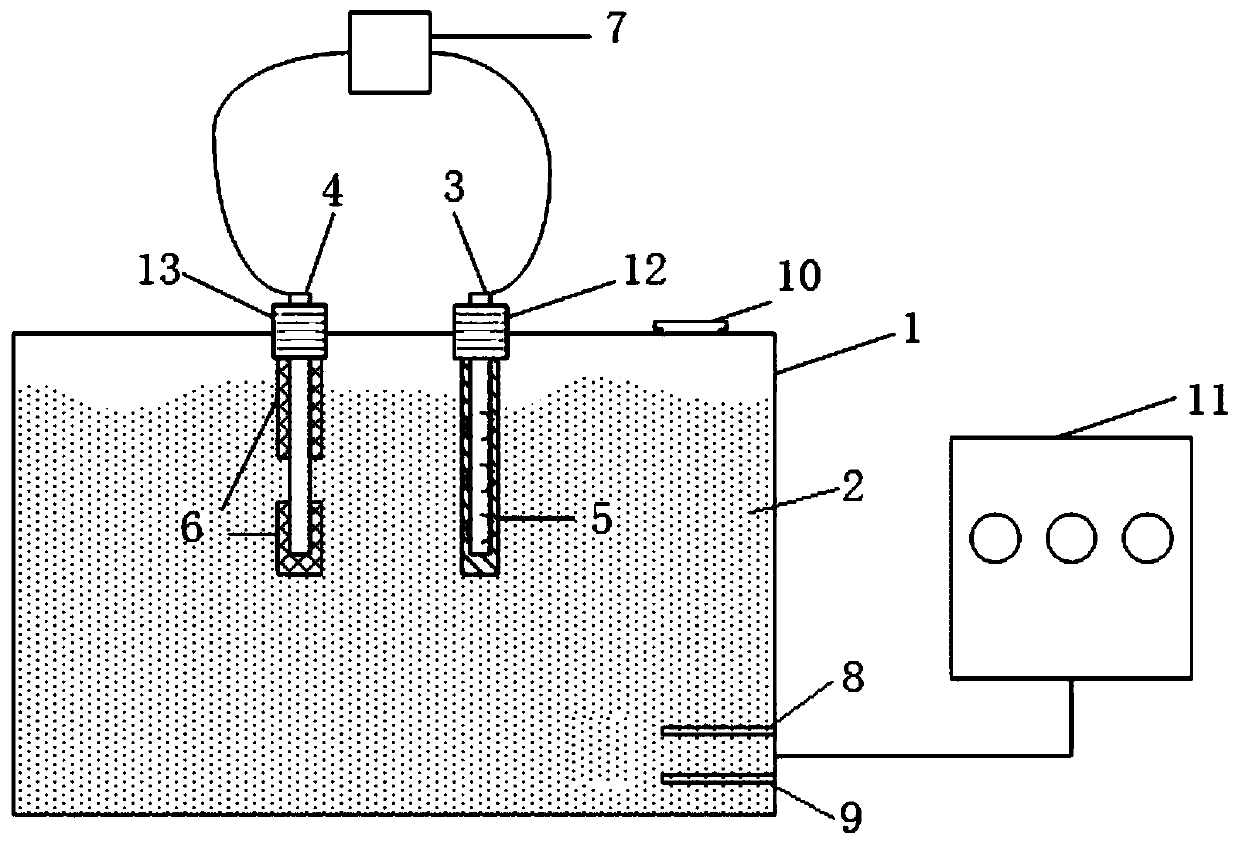

[0066] In this example, the galvanic corrosion of cladding and core materials of 316L / Q345 composite steel bar in the ocean full immersion area environment is simulated.

[0067] Cut a 316L / Q345 composite steel bar into sections A and B with a length of 200mm, use wire cutting to cut off the cladding (316L material) of the composite steel bar in section A, keep the core material (Q345 material), and cut the core material Process it into a cylinder, and then grind and polish the core material to obtain core material sample 3. Composite steel bars in section B were pickled to remove scale, then ground and polished to obtain composite steel bar sample 4.

[0068] Degrease and neutralize the core material sample 3 and the composite steel bar sample 4 respectively, then wash and dehydrate; measure the cylinder diameter D and length L of the core material sample 3 with a micrometer, and calculate its mass M 0 .

[0069] The insulating sleeve 5 of the core material sample and the i...

Embodiment 2

[0075] In this example, a simulation test is carried out on the galvanic corrosion of the cladding and core material of 2205 / Q235 composite steel bars in the ocean tidal range environment.

[0076] Cut a 2205 / Q235 composite steel bar into sections A and B with a length of 300mm, cut off the cladding (2205 material) of the composite steel bar in section A by wire cutting, and only keep the core material (material is Q235). The core material was processed into a cylinder, and then the core material was ground and polished to obtain a core material sample 3 . Composite steel bars in section B were pickled to remove scale, then ground and polished to obtain composite steel bar sample 4.

[0077] The core material sample 3 and the composite steel bar sample 4 were degreased and neutralized, and then cleaned and dehydrated. Measure the cylinder diameter D and length L of the core material sample 3 with a micrometer, and calculate its mass M 0 .

[0078] The insulating sleeve 5 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com