Device and method for measuring gas pressure and components of cavity of extremely-small sealing device

A technology of gas pressure and measuring devices, which is applied in the direction of measuring devices, measuring fluid pressure, simultaneous measurement of multiple hydraulic valves, etc., can solve the problems that cannot meet the needs of packaging technology evaluation of extremely small sealing devices, and achieve the purpose of overcoming the quality discrimination effect, The effect of low measurement lower limit and small measurement uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

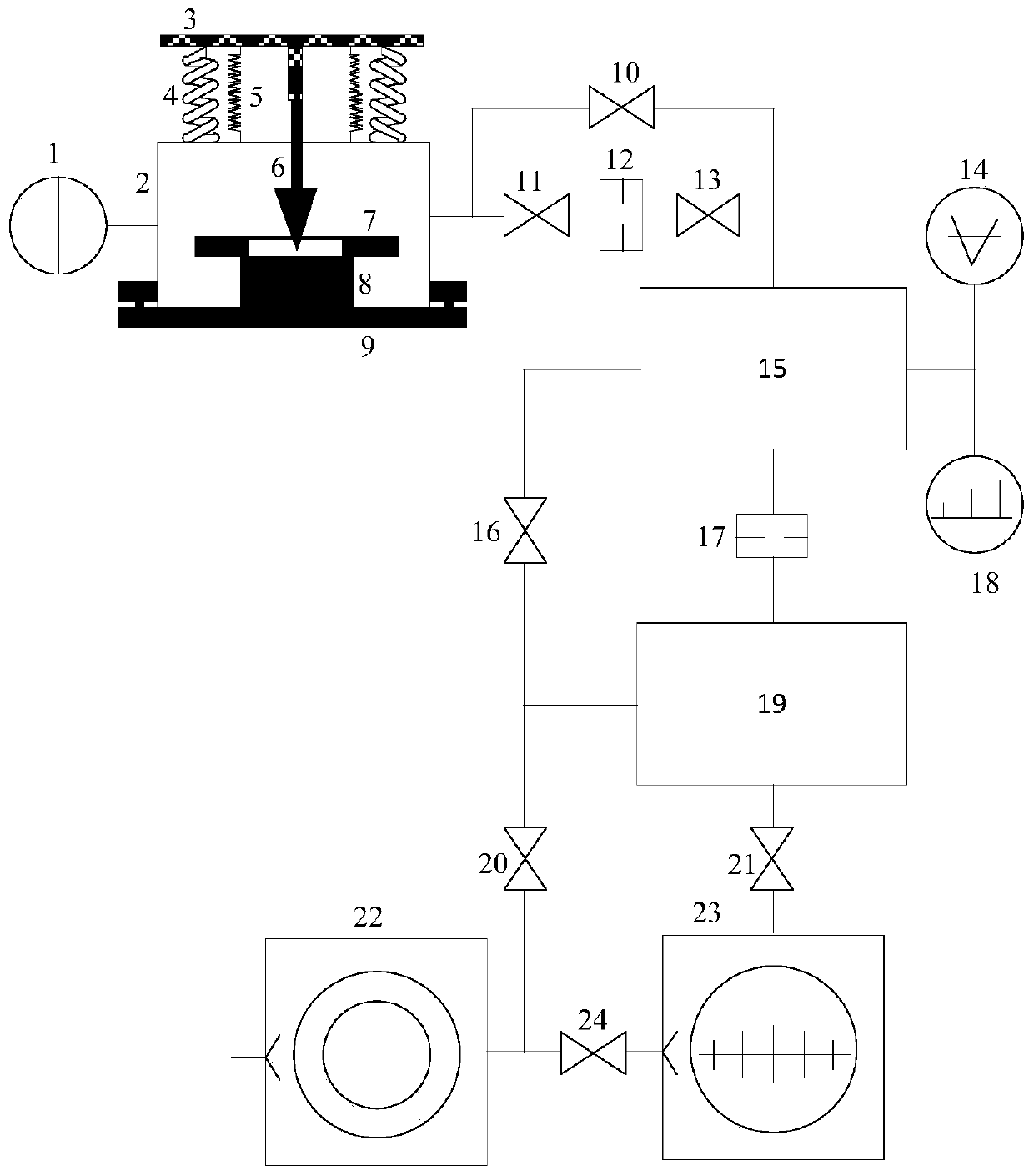

[0037] The invention provides a device and method for measuring the gas pressure and composition of the cavity of a very small sealed device, such as figure 1 As shown, including vacuum gauge A 1, vacuum gauge B 14, pressure measurement chamber 2, puncture structure, pressure ring 7 of the sealing device under test, 8 sealing device under test, mounting flange 9 of the sealing device under test, and stop valve A 10 , cut-off valve B 11, cut-off valve C 13, sampling hole 12, component measurement chamber 15, cut-off valve A 16, cut-off valve B 20, cut-off valve C 21, cut-off valve D 24, evacuation small hole 17, partial pressure mass spectrometry Gauge 18, evacuated cavity 19, rough vacuum pump 22, high vacuum pump 23 and corresponding pipeline.

[0038] Among them, the vacuum gauge A 1 is installed on the pressure measurement chamber 2 to realize the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com