Transmission shaft, transmission shaft assembly and transmission shaft welding method

A welding method and transmission shaft technology, applied in welding equipment, couplings, non-electric welding equipment, etc., can solve the problems of high degree of automation, strong professionalism, and large limitations, so as to achieve no loss of welding strength and improve welding seam. Good strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Many specific details are set forth in the following description to facilitate a full understanding of the embodiments of the present application. However, the embodiment of the present application can be implemented in many other ways different from those described here, and those skilled in the art can make similar promotions without violating the connotation of the embodiment of the present application. Implemented restrictions.

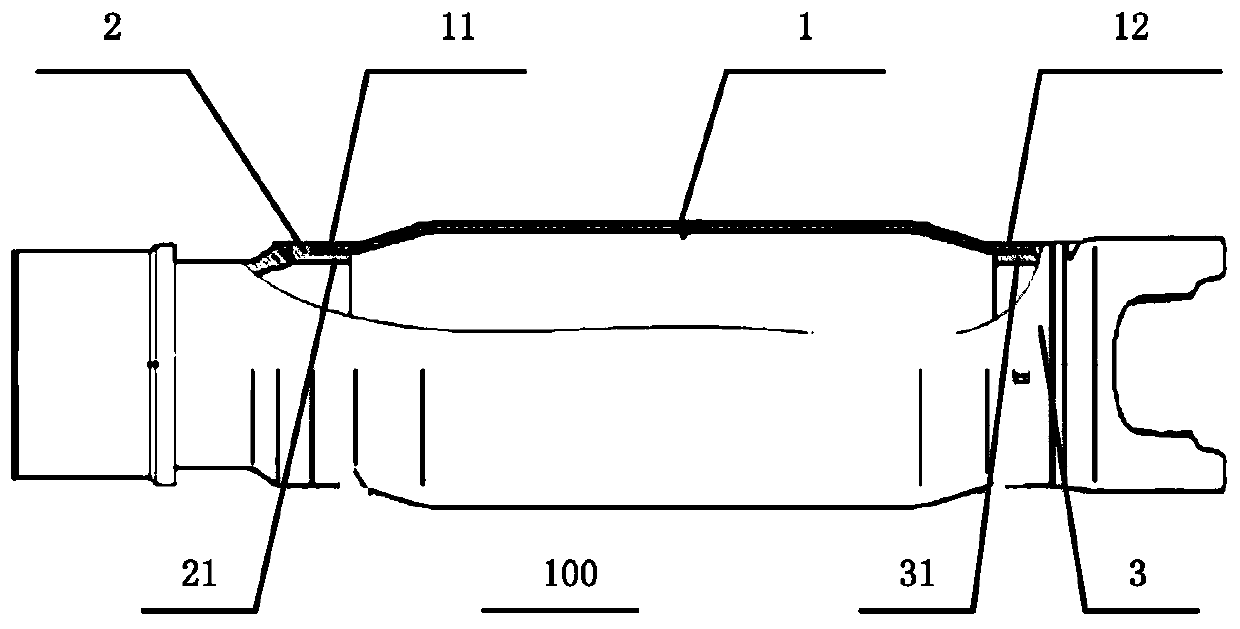

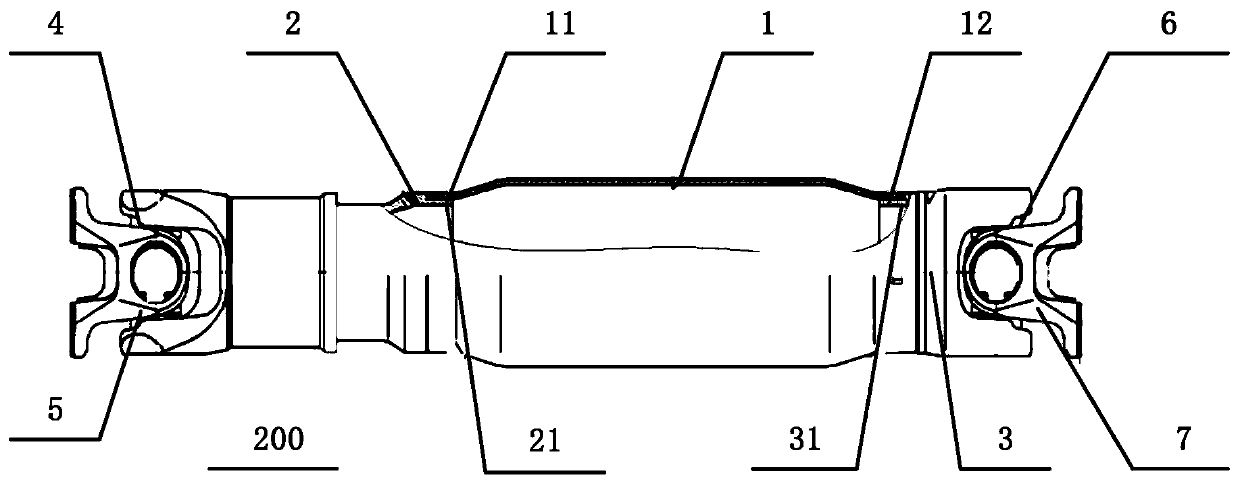

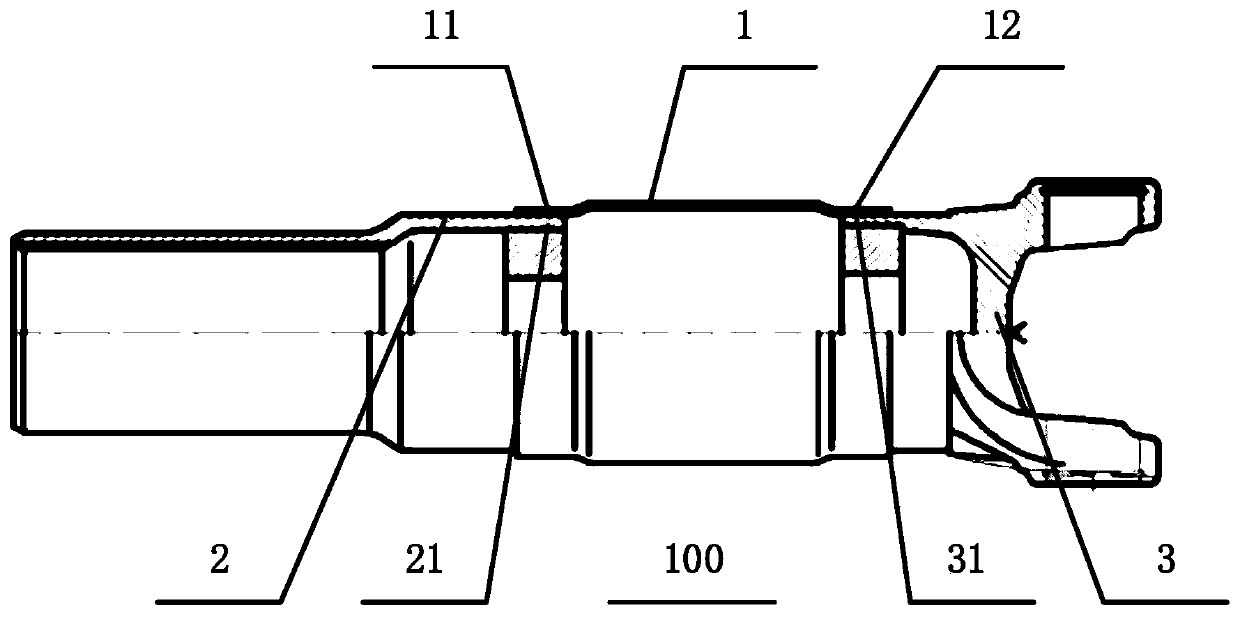

[0039] The first embodiment of the present application provides a drive shaft, figure 1 It is a structural schematic diagram of a drive shaft provided in the first embodiment of the present application;

[0040] combine figure 1 As shown, the transmission shaft 100 includes a shaft tube 1 , a spline sleeve 2 and a universal joint yoke 3 . Wherein, the shaft tube 1 has a first end portion 11 and a second end portion 12 , and the first end portion 11 and the second end portion 12 are opposite ends of the shaft tube 1 . The spline sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com