Impact-resistant and wear-resistant composite material for hydraulic structure

A technology for hydraulic structures and composite materials, which is applied in the field of anti-impact and wear-resistant composite materials for hydraulic structures, can solve the problems of poor anti-impact and anti-wear properties, and achieve the advantages of reduced adsorption, excellent durability, and improved durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

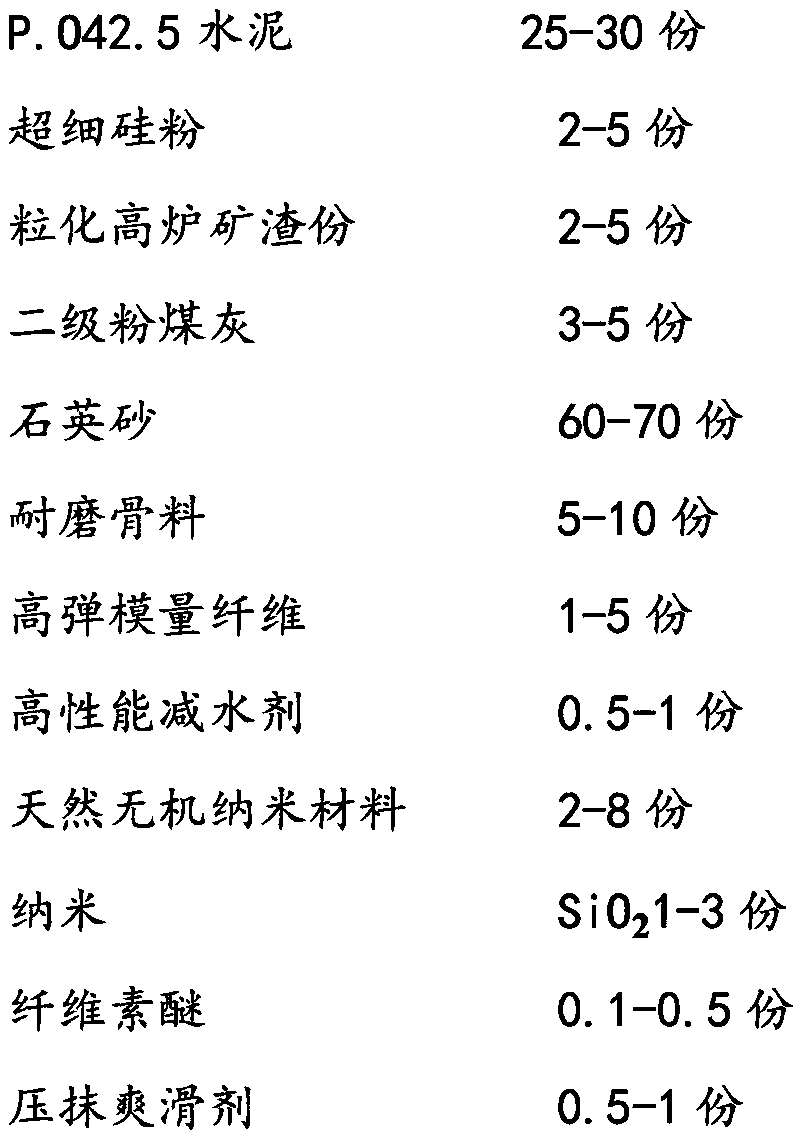

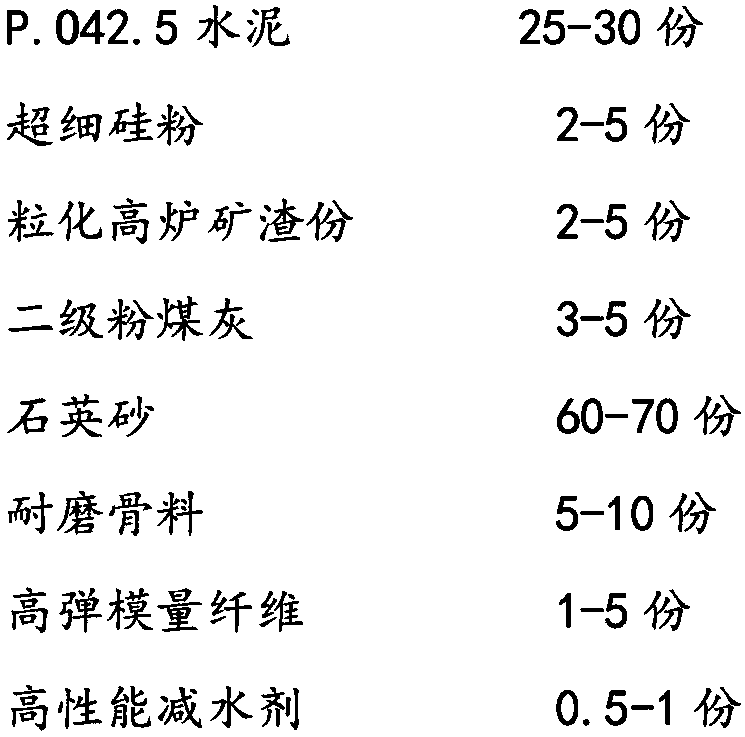

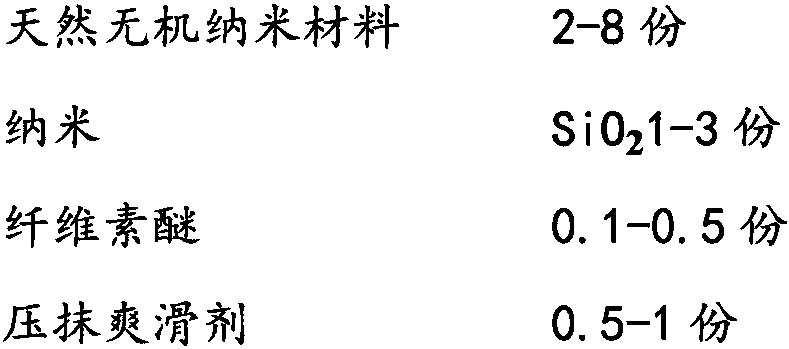

[0030] P.042.5 25 parts of cement, 2 parts of ultra-fine silica fume, 2 parts of granulated blast furnace slag, 3 parts of secondary fly ash, 60 parts of quartz sand, 5 parts of wear-resistant aggregate, 1 part of high elastic modulus fiber, High-performance water reducing agent 0.5 parts, natural inorganic nano materials 2 parts, nano SiO 2 1 part, 0.1 part of cellulose ether, 0.5 part of press slip agent.

[0031] Among them, the activity index of ultrafine silica fume reaches S105; quartz sand is 20-80 mesh; wear-resistant aggregate is emery or steel jade; the nominal length of high elastic modulus fiber is 3-6mm, and the tensile strength is greater than 1200N / mm 2 The water reduction rate of the high-performance water reducing agent is greater than 30%; the natural inorganic nano-materials are natural minerals and have a layered structure.

[0032] A method for preparing an impact-resistant and wear-resistant composite material for hydraulic structures. The raw materials inclu...

Embodiment 2

[0038] P.042.5 30 parts of cement, 5 parts of superfine silica fume, 5 parts of granulated blast furnace slag, 5 parts of secondary fly ash, 70 parts of quartz sand, 10 parts of wear-resistant aggregate, 5 parts of high elastic modulus fiber, 1 part of high performance water reducing agent, 8 parts of natural inorganic nano material, nano SiO 2 3 parts, 0.5 parts of cellulose ether, 1 part of press smoothing agent.

[0039] Among them, the activity index of ultrafine silica fume reaches S105; quartz sand is 20-80 mesh; wear-resistant aggregate is emery or steel jade; the nominal length of high elastic modulus fiber is 3-6mm, and the tensile strength is greater than 1200N / mm 2 The water reduction rate of the high-performance water reducing agent is greater than 30%; the natural inorganic nano-materials are natural minerals and have a layered structure.

[0040] A method for preparing an impact-resistant and wear-resistant composite material for hydraulic structures. The raw materia...

Embodiment 3

[0042] P.042.5 28 parts of cement, 3 parts of ultra-fine silica fume, 3 parts of granulated blast furnace slag, 4 parts of secondary fly ash, 65 parts of quartz sand, 7 parts of wear-resistant aggregate, 3 parts of high elastic modulus fiber, 0.8 parts of high performance water reducing agent, 5 parts of natural inorganic nano material, nano SiO 2 2 parts, 0.3 parts of cellulose ether, 0.8 parts of press slip agent.

[0043] Among them, the activity index of ultrafine silica fume reaches S105; quartz sand is 20-80 mesh; wear-resistant aggregate is emery or steel jade; the nominal length of high elastic modulus fiber is 3-6mm, and the tensile strength is greater than 1200N / mm 2 The water reduction rate of the high-performance water reducing agent is greater than 30%; the natural inorganic nano-materials are natural minerals and have a layered structure.

[0044] A method for preparing an impact-resistant and wear-resistant composite material for hydraulic buildings. The raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com