Comprehensive utilization method for Bayer red mud

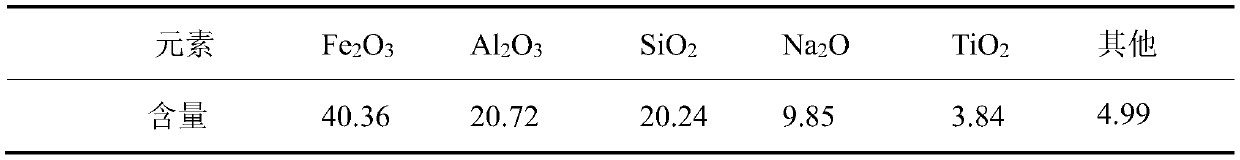

A technology of Bayer red mud and red mud, which is applied in the direction of chemical instruments and methods, alkali metal compounds, process efficiency improvement, etc. It can solve the problems affecting the performance of building materials such as cement and limit the application of red mud, and achieve low cost and high purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for comprehensive utilization of Bayer red mud, mixing Bayer red mud with concentrated sulfuric acid, using sulfuric acid to completely salinize Bayer red mud under low temperature conditions to obtain sulfated red mud; Muffle furnace roasting, roasting time 40min, soak the roasted product in water, water immersion temperature 50°C, time 30min, and then separate solid and liquid to obtain red mud oxidation clinker rich in sodium and low iron and high iron; add sodium carbonate to the leachate , the pH of the solution was adjusted to be 9, and the solution was left to stand for 30 minutes at 50° C., and then the solution was filtered, and the obtained filtrate was evaporated and crystallized to obtain sodium sulfate crystals. The purity of sodium sulfate in this example was 98.4%; the red mud The oxidized clinker and NaOH solution are reacted after mixing in a ratio of 8:1; the reaction temperature is 150°C; the constant temperature time is 120min; the concentrat...

Embodiment 2

[0032] A method for comprehensive utilization of Bayer red mud, mixing Bayer red mud with concentrated sulfuric acid, using sulfuric acid to completely salinize Bayer red mud at low temperature to obtain sulfated red mud; Muffle furnace roasting, roasting time 40min, soak the roasted product in water, water immersion temperature 50°C, time 30min, and then separate solid and liquid to obtain red mud oxidation clinker rich in sodium and low iron and high iron; add sodium carbonate to the leachate , adjust the pH of the solution to be 9, let it stand for 30min under the environment of 50°C, then filter the solution, and evaporate and crystallize the obtained filtrate to obtain sodium sulfate crystals. The purity of sodium sulfate in this example is 98.2%; the red mud The oxidized clinker and NaOH solution are reacted after mixing in a ratio of 8:1; the reaction temperature is 150°C; the constant temperature time is 120min; the concentration of the NaOH solution is 190g / L; Dry and...

Embodiment 3

[0034] A method for comprehensive utilization of Bayer red mud, mixing Bayer red mud with concentrated sulfuric acid, using sulfuric acid to completely salinize Bayer red mud under low temperature conditions to obtain sulfated red mud; Muffle furnace roasting, roasting time 40min, soak the roasted product in water, water immersion temperature 50°C, time 30min, and then separate solid and liquid to obtain red mud oxidation clinker rich in sodium and low iron and high iron; add sodium carbonate to the leachate , adjust the pH of the solution to be 8, let it stand for 30min under the environment of 50°C, then filter the solution, and evaporate and crystallize the obtained filtrate to obtain sodium sulfate crystals. The purity of sodium sulfate in this example is 97.9%; the red mud The oxidized clinker and NaOH solution were mixed in a ratio of 7:1 and then reacted; the reaction temperature was 150°C; the constant temperature time was 120min; the concentration of the NaOH solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com