Device capable of conveniently vertically aligning and positioning steel concrete composite tube during tower crane hoisting

A technology of aligning, positioning, and combining pipes, which is applied in the directions of transportation, packaging, and load-hanging components. It can solve the problems of large crane occupation, impact on stability, and high construction costs, and achieve enhanced upper port strength, lower port strength, and structure. The effect of durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

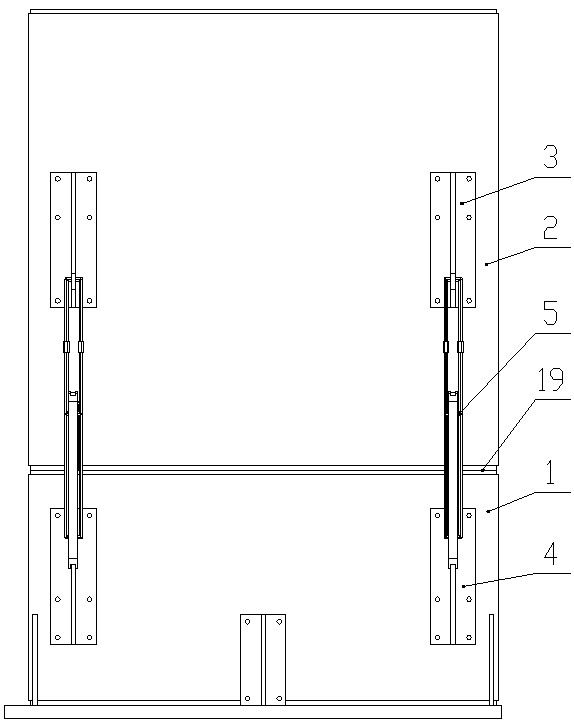

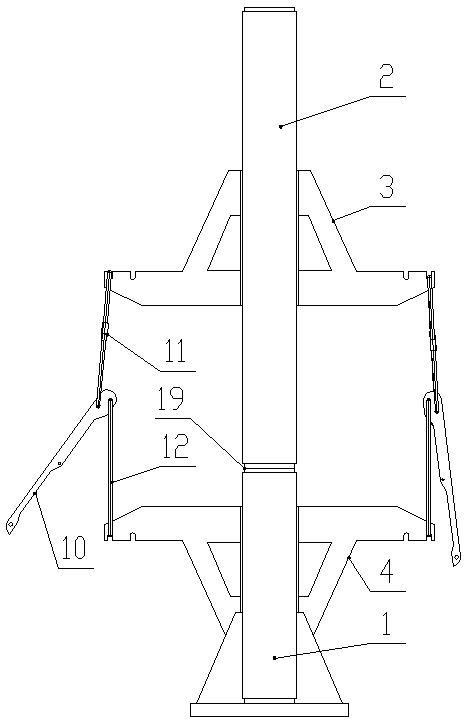

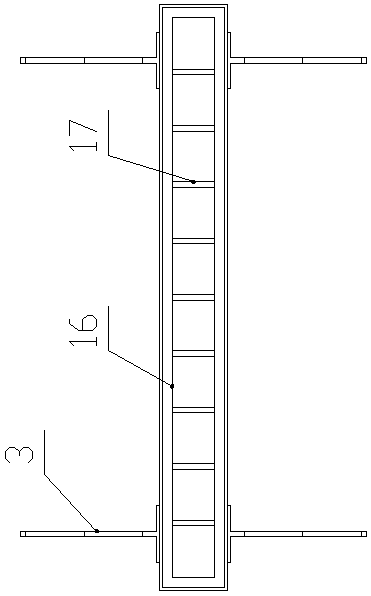

[0040] Embodiment one: if Figure 1-Figure 10 As shown, the convenient vertical alignment and positioning device for tower crane hoisting steel-concrete composite pipe of the present invention includes a fixed lower layer steel-concrete composite pipe 1 and an upper layer steel-concrete composite pipe 2 arranged on the top of the lower layer steel-concrete composite pipe 1 to be fixed, The upper steel-concrete composite pipe 2 has the same structure as the lower steel-concrete composite pipe 1; the lower end of the upper steel-concrete composite pipe 2 is provided with a vertical drop guide convex structure, and the inner side of the upper end surface of the lower steel-concrete composite pipe 1 is provided with a vertical drop guide structure. There are several groups of temporary positioning devices arranged between the lower steel-concrete composite pipe 1 and the lower steel-concrete composite pipe 1, and each group of temporary positioning devices includes two sets of push...

Embodiment 2

[0061] Embodiment two: if Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the upper tie rod assembly 11 includes an upper hanging ring 21, a lower hanging ring 22 and a turnbuckle 23, and the upper end of the upper hanging ring 21 is hooked on the upper part of the upper support plate 7. In the positioning groove 9, the upper end of the turnbuckle 23 is connected with the bottom of the upper hanging ring 21, the lower end of the lower hanging ring 22 is pierced and connected in the front pull hole, and the lower end of the turnbuckle 23 is connected with the top of the lower hanging ring 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com