Green rust material and preparation method and application thereof

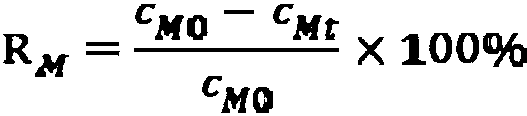

A green rust and iron-based technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of limited adsorption capacity, small specific surface area and narrow application range of heavy metal pollutants, etc. Achieve the effect of excellent heavy metal adsorption performance, large pH application range, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Influence of the molar ratio of ferrous ions and ferric ions on the adsorption performance of the prepared novel green rust adsorbent

[0026] Weigh sulfuric acid according to the molar ratio of ferrous ion to ferric ion 1:1, 1.5:1, 1.8:1, 2:1, 3:1, 4:1, 4.2:1, 4.5:1, 5:1 Ferrous and ferric sulfate were mixed and stirred evenly to obtain nine groups of iron-based reagents. Dissolve the nine groups of iron-based reagents in water, and stir under sealed conditions until the iron-based reagents are completely dissolved to obtain nine groups of iron-based solutions, in which the concentration of ferrous ions is 0.2M. Nine groups of sodium hydroxide were weighed according to the molar ratio of hydroxide to total iron ions (ferrous ion + ferric ion) of 3:1. Dissolve nine groups of sodium hydroxide into water, stir under sealed conditions, and prepare nine groups of 2M sodium hydroxide solutions. Nine groups of β-cyclodextrin were weighed according to the molar rat...

Embodiment 2

[0033] Example 2 Effect of Hydroxide and Total Iron Ion Molar Ratio on the Adsorption Performance of the Prepared Novel Green Rust Adsorbent

[0034] Weigh ferrous sulfate and ferric sulfate respectively according to the molar ratio of ferrous ions and ferric ions of 4:1, mix and stir evenly to obtain an iron-based reagent. Dissolve the iron-based reagent in water, and stir under sealed conditions until the iron-based reagent is completely dissolved to obtain an iron-based solution in which the concentration of ferrous ions is 0.4M. According to the molar ratio of hydroxide to total iron ion (ferrous ion + ferric ion) 2.5:1, 2.7:1, 2.9:1, 3:1, 3.5:1, 4:1, 4.1:1, 4.3: 1. Weigh nine groups of sodium hydroxide at 4.5:1 respectively. Dissolve nine groups of sodium hydroxide into water, stir under sealed conditions, and prepare nine groups of 3.5M sodium hydroxide solutions. Nine groups of β-cyclodextrins were weighed according to the molar ratio of β-cyclodextrin to total iron i...

Embodiment 3

[0040] Example 3 Effect of β-cyclodextrin to total iron ion molar ratio on the adsorption performance of the prepared novel green rust adsorbent

[0041] Weigh ferrous sulfate and ferric sulfate respectively according to the molar ratio of ferrous ions and ferric ions of 4:1, mix and stir evenly to obtain an iron-based reagent. Dissolve the iron-based reagent in water, and stir under sealed conditions until the iron-based reagent is completely dissolved to obtain an iron-based solution in which the concentration of ferrous ions is 0.6M. Sodium hydroxide was weighed according to the molar ratio of hydroxide ions to total iron ions (ferrous ions + ferric ions) of 4:1. Dissolve sodium hydroxide in water and stir under sealed conditions to prepare 5M sodium hydroxide solution. According to the molar ratio of β-cyclodextrin to total iron ion (ferrous ion + ferric ion) 1:100, 1.5:100, 2:100, 2.5:100, 5:100, 7.5:100, 8:100, 8. Weigh nine groups of β-cyclodextrin at 5:100 and 9:100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com