High-elasticity intelligent clothes based on liquid metal as well as preparation method and application of high-elasticity intelligent clothes

A liquid metal, high-elasticity technology, applied in applications, protective clothing, home appliances, etc., can solve the problems of conductive ink cracking, stretchable micro-nano silver flake conductive ink is expensive, not suitable for clothing, etc., to achieve excellent stretching performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] This example is used to illustrate the preparation of liquid metal conductive ink.

[0100] Add 0.3g polyethylene oxide and 5uL fluorocarbon surfactant into 10mL distilled water, stir for 24h to fully dissolve. After the polyethylene oxide is fully dissolved, take 3 ml of ethanol and place it in a plastic tube, and add 5 g of liquid indium gallium tin alloy (In22%wt Ga 68%wt Sn 10%wt) at the same time. Sonicate for 60 s at 30% amplitude with an ultrasonic cell disruptor to obtain a gray liquid metal dispersion in ethanol. Centrifuge the dispersion at a speed of 2000 rpm for 2 minutes, remove the supernatant, and seal it for long-term storage. Before use, add 2mL of polyethylene oxide aqueous solution into the precipitate of liquid metal particles, stir well and then use it.

Embodiment 2

[0102] This example is used to illustrate the preparation of liquid metal conductive ink.

[0103] Add 5g of polyvinylpyrrolidone into 100mL of n-decyl alcohol, stir for 24 hours to fully dissolve, and make an alcoholic solution of polyvinylpyrrolidone. After the polyvinylpyrrolidone (PVP) was fully dissolved, 35 ml of the solution was taken and placed in a beaker, and 100 g of liquid indium gallium eutectic alloy (Ga 75.5%wt In 24.5%wt) was added at the same time. Use an electric grinder to stir the liquid metal at a speed of 20,000 rpm for 20 minutes. The metal is dispersed into small particles in the solution to obtain a gray liquid metal ink, which can be used after stirring evenly.

Embodiment 3

[0105] This example is used to illustrate the preparation of flexible and stretchable conductive circuits on the surface of smart clothing.

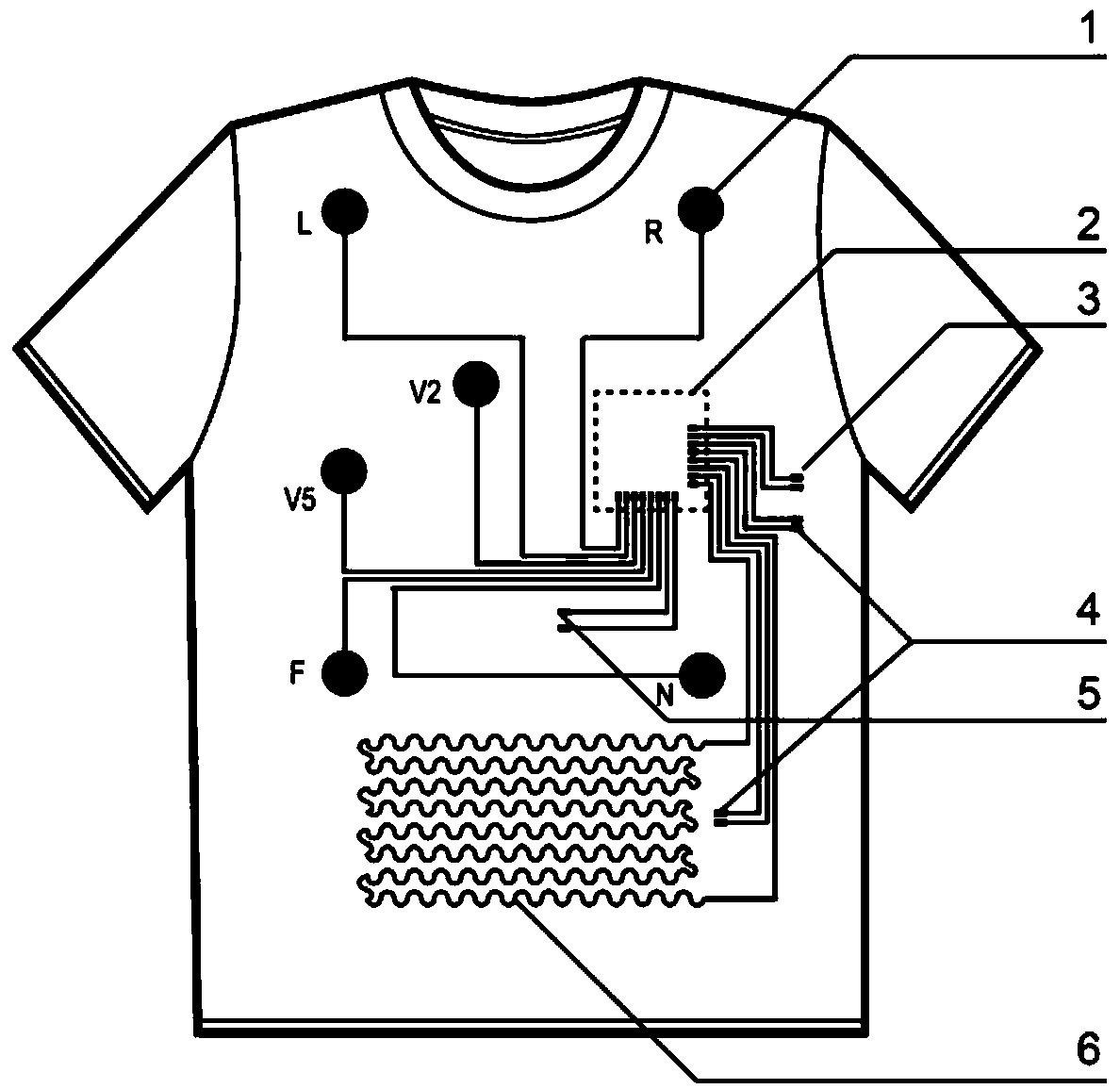

[0106] The present invention uses the screen printing station to adopt the mode of screen printing to print the T-shirt screen printing ink according to the figure 1 The pattern is printed on the inner side of the elastic long-sleeved swimsuit as the base layer, and dried at 80 degrees Celsius for 20 minutes. Then continue to use the screen printing station to print the liquid metal ink of Example 1 or 2 on the base layer, and dry it at 80 degrees Celsius for 30 minutes or at room temperature for 24 hours. Finally, the T-shirt screen printing ink is printed on the liquid metal ink layer by a screen printing station to encapsulate the liquid metal layer. And dry at 80 degrees Celsius for 20 minutes. After curing, stretching the elastic long-sleeved swimsuit by 30 percent made the liquid metal ink conductive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com