A kind of embedded micro-pump driven heat dissipation structure and heat dissipation method

A heat dissipation structure and heat dissipation method technology, which is applied to electric vehicles, generators/motors, and modification through conduction heat transfer, etc., can solve the problems of high chip surface temperature and poor heat dissipation effect, and achieve enhanced heat exchange efficiency and enhanced The effect of heat exchange power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

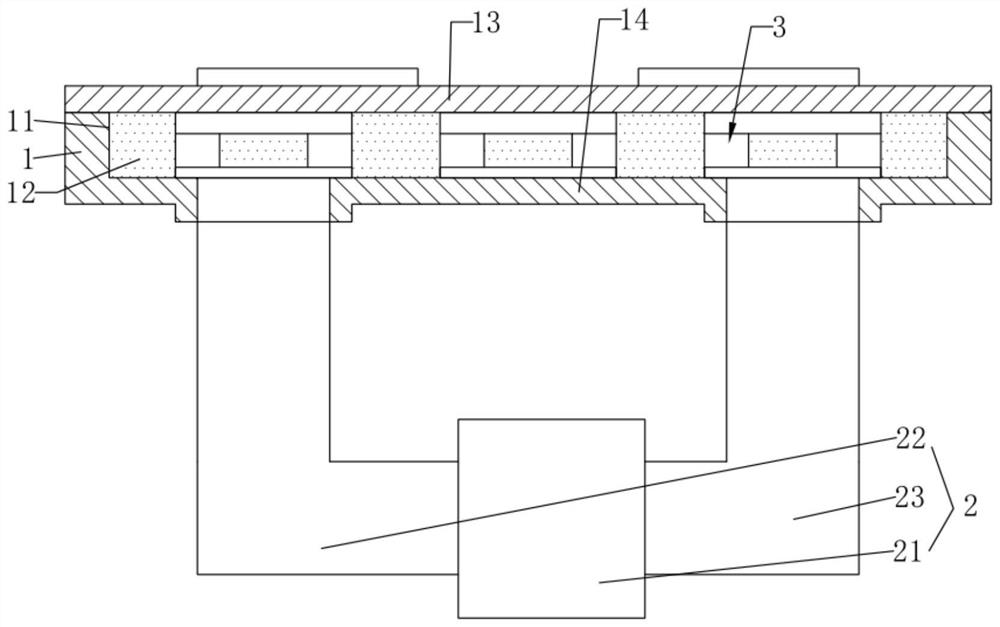

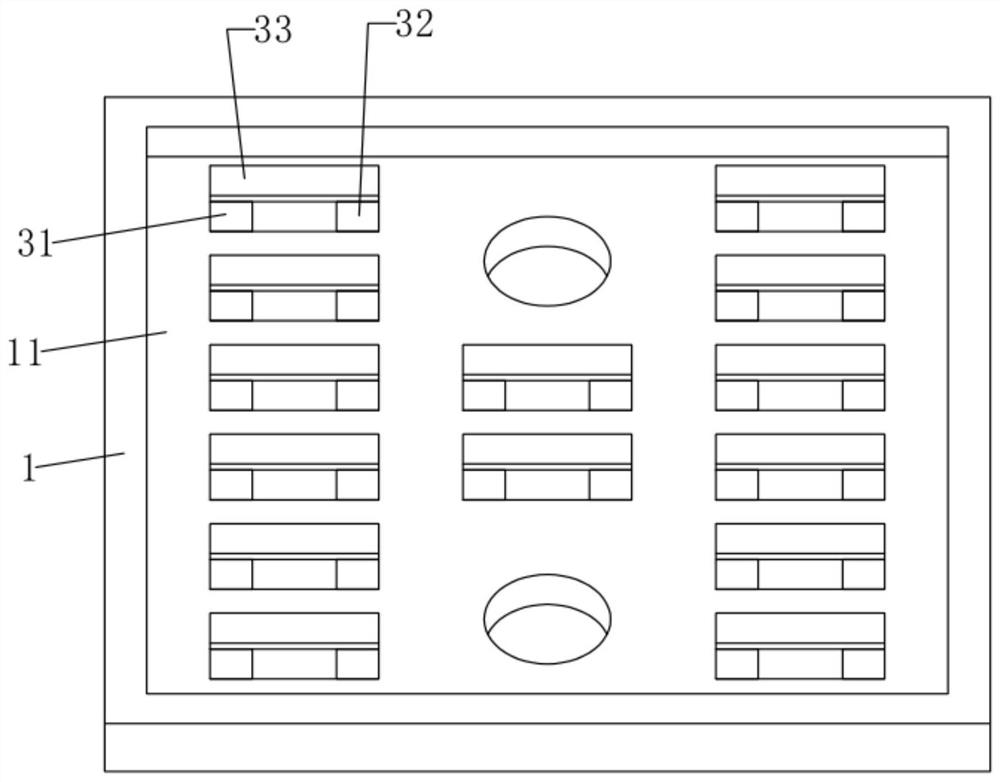

[0044] An embedded micropump-driven cooling structure, such as Figure 1 to Figure 5 As shown, a heat dissipation housing 1 is included, and a heat dissipation chamber 11 is formed inside the heat dissipation housing 1; a heat dissipation working medium 12 is filled in the heat dissipation chamber 11; The heat dissipation working medium 12 is continuously extracted and continuously input into the embedded micro-channel forced cooling module 2 . During use, the heat dissipation housing 1 is installed and fixed on one side of the device to be dissipated, and the heat of the device to be dissipated passes through the heat dissipation housing 1 through heat transfer, and exchanges heat with the internal heat dissipation working medium 12 . The internal heat dissipation working medium 12 continuously flows out of the heat dissipation housing 1 and continuously flows into the heat dissipation housing 1 to achieve continuous heat exchange, thereby achieving a cooling effect.

[0045...

Embodiment 2

[0111] A heat dissipation method based on an embedded micropump 21 driven heat dissipation structure, comprising the following heat dissipation steps:

[0112] S1, start the micropump 21, and the internal heat dissipation working medium 12 circulates to dissipate heat;

[0113] S2. Detect the surface temperature of the device to be dissipated, and select heat recovery or forced heat dissipation.

[0114] In step S2, comprising the following steps:

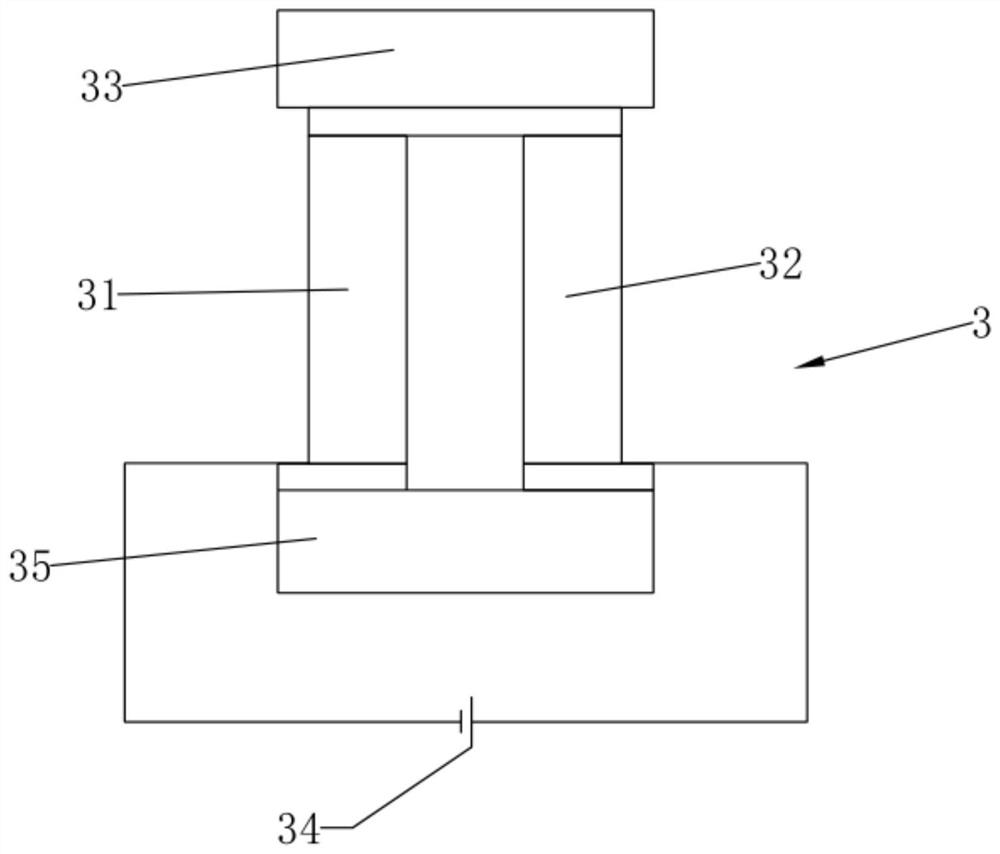

[0115] S21. When the surface temperature of the device to be dissipated is within the heat dissipation range of the embedded micro-channel forced cooling module 2, the first semiconductor column 31 and the second semiconductor column 32 supply power to the outside.

[0116] S22. When the surface temperature of the device to be dissipated is higher than the heat dissipation range of the embedded micro-channel forced cooling module 2, supply power to the first semiconductor column 31 and the second semiconductor column 32 to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com