Middle frame assembly, preparation method of middle frame assembly and electronic equipment

A technology for electronic equipment and frame components, applied in circuits, electrical components, antenna parts and other directions, can solve the problems of affecting the transmission and reception of antenna signals, uneven laser engraving area, and clutter, etc., to improve the reliability of conduction, The effect of ensuring reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

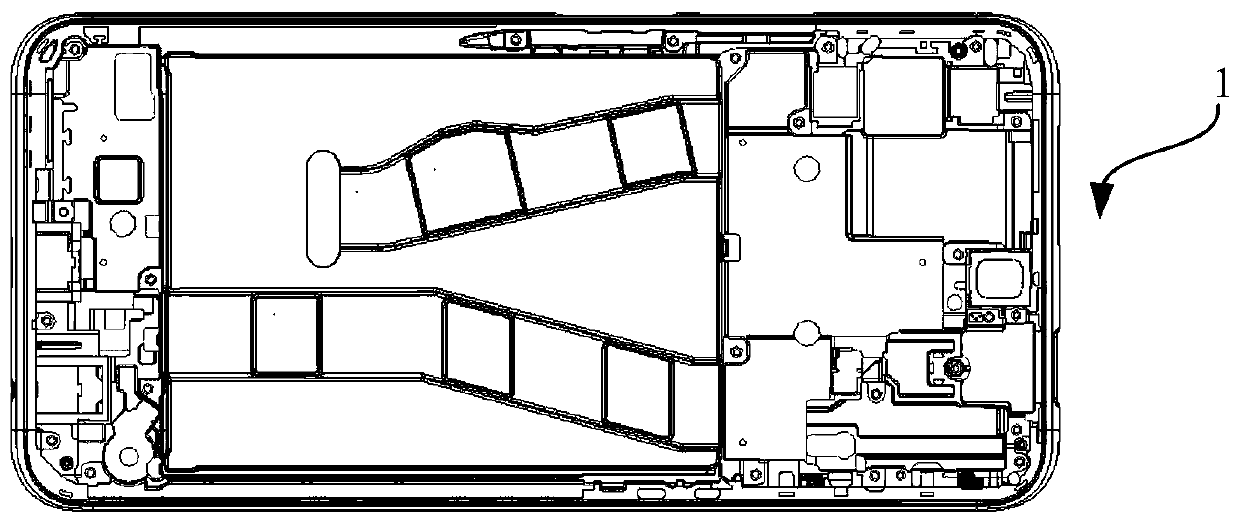

[0057] On the other hand, the embodiment of the present application also provides a method for preparing a middle frame assembly, refer to Picture 10 , The preparation method of the middle frame assembly includes the following steps:

[0058] S01: Lay the antenna covered with oxide film on the middle frame body.

[0059] S02: Remove the oxide film on the feed part of the antenna, so that the oxide film forms a hollow area at the position of the feed part of the antenna.

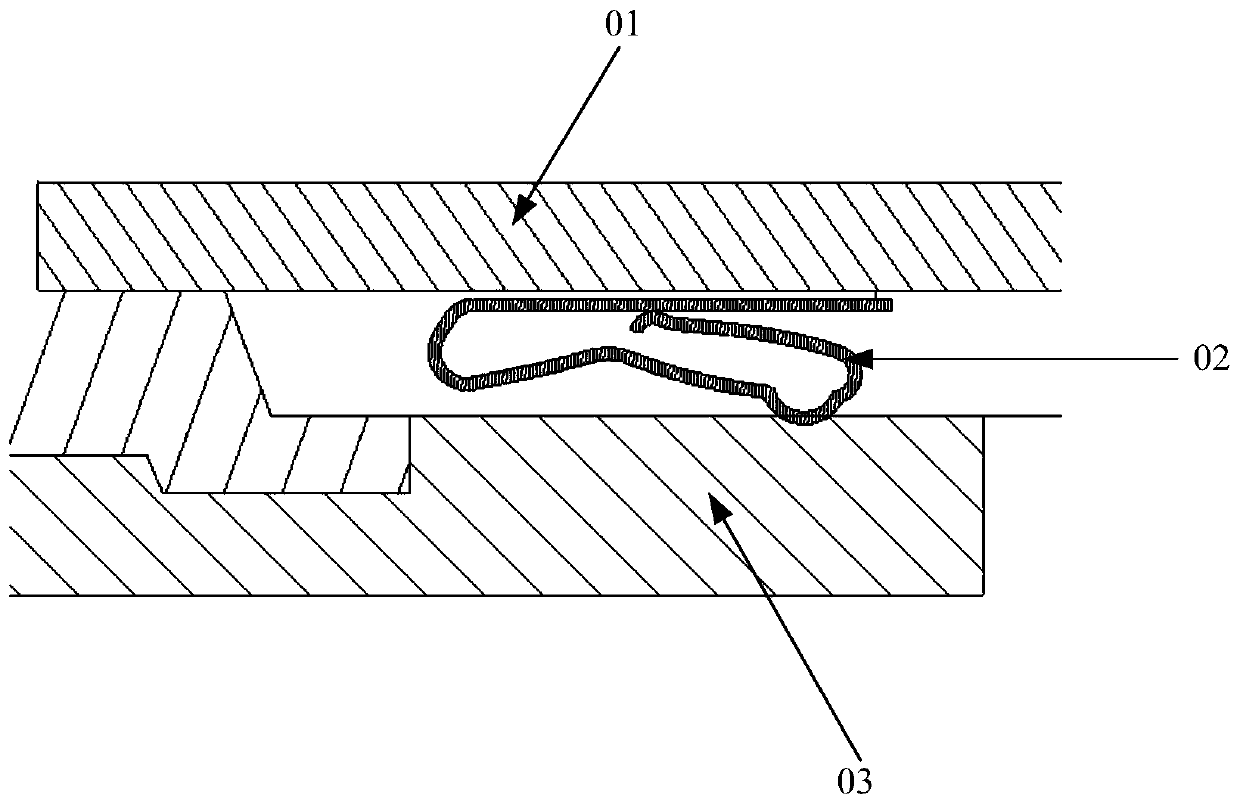

[0060] The oxide film on the feeder part on the antenna is removed. The advantage achieved by this process is that the oxide film has poor conductivity, and exposing the antenna can improve the conduction performance between the antenna and the metal elastic member.

[0061] S03: Apply a conductive coating so that the conductive coating at least covers the hollow area.

[0062] In the method for preparing the middle frame assembly provided by the embodiment of the present application, in order to expose the feeding p...

Embodiment 1

[0066] S011: Lay the antenna covered with oxide film on the middle frame body.

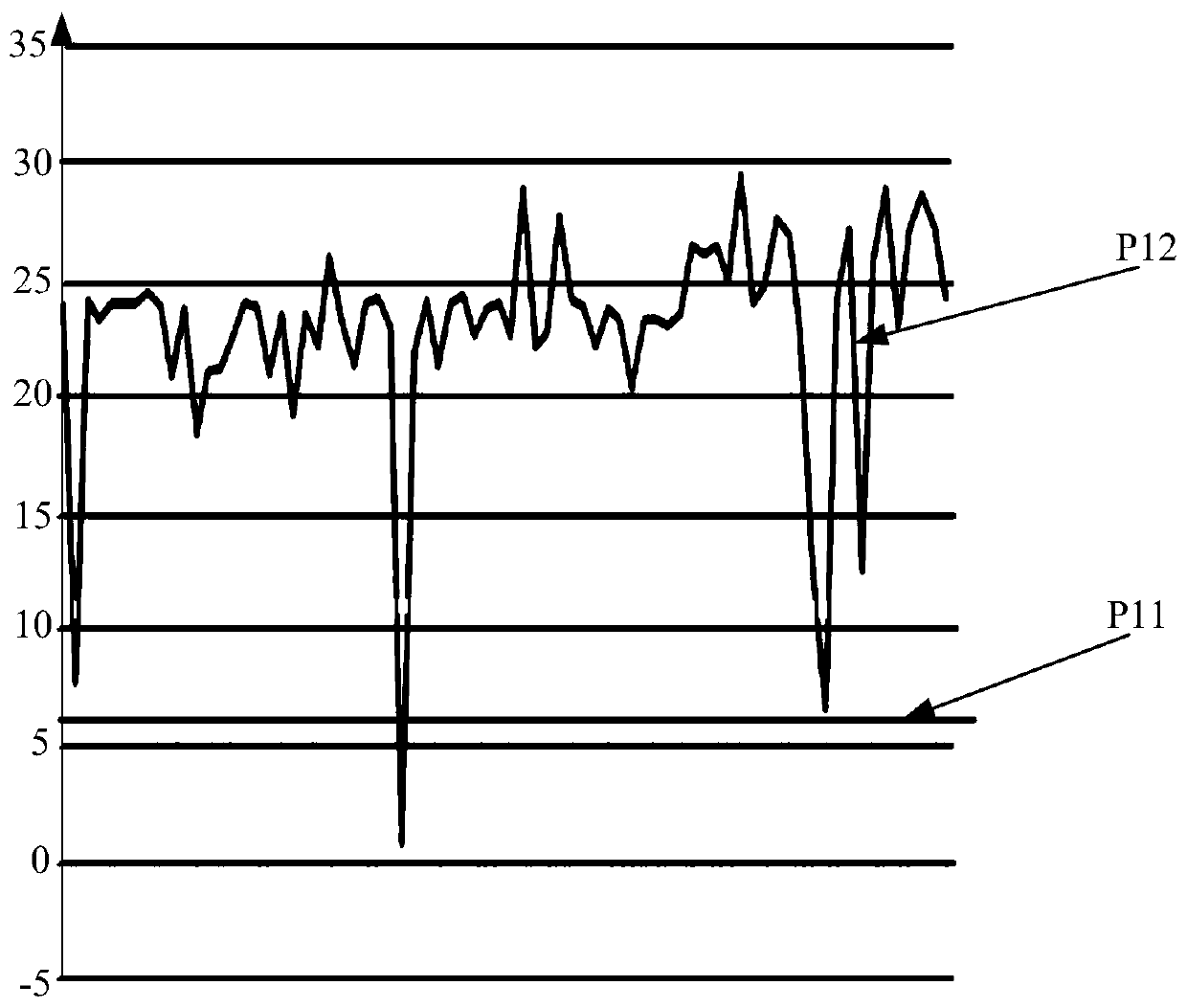

[0067] S021: The oxide film on the power feeding part of the laser engraving antenna, so that the oxide film forms a hollow area at the position of the power feeding part of the antenna.

[0068] S031: Use alcohol to clean the impurities after laser engraving and dry them.

[0069] S041: Print the conductive coating so that the conductive coating at least covers the hollow area.

[0070] S051: Dry the printed conductive coating.

Embodiment 2

[0072] S012: Lay the antenna covered with oxide film on the middle frame body.

[0073] S022: The oxide film on the power feeding part of the laser carving antenna, so that the oxide film is located at the position of the power feeding part of the antenna to form a hollow area.

[0074] S032: Use alcohol to clean the impurities after laser carving and dry it.

[0075] S042: Three-dimensional printing of the conductive coating so that the conductive coating at least covers the hollow area.

[0076] S052: Dry the conductive coating for 3D printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com