Electrochromic display panel and electronic paper

An electrochromic and display panel technology, used in nonlinear optics, instruments, optics, etc., can solve the problems of affecting dielectric insulation strength, low dielectric insulation strength, and large electric field non-uniformity, and achieve enhanced conductivity and response speed. , The effect of eliminating packaging steps and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

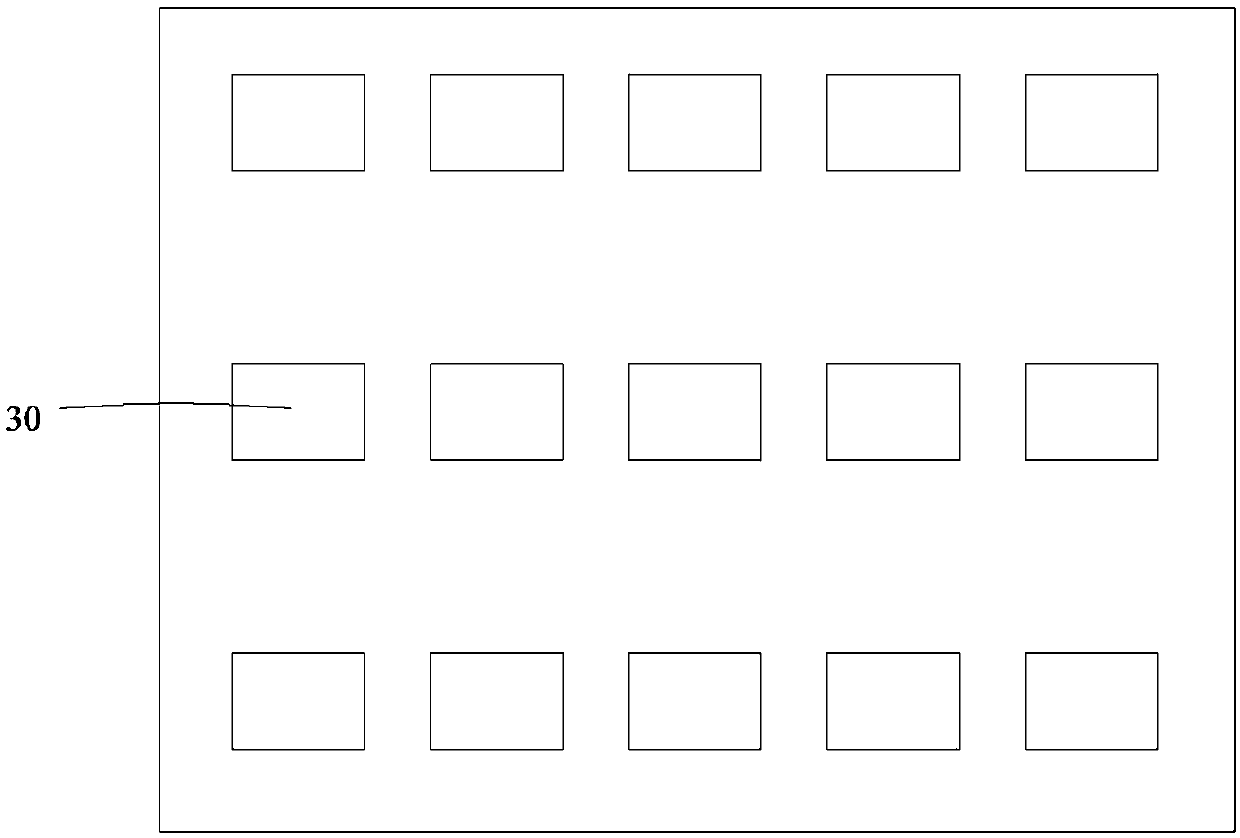

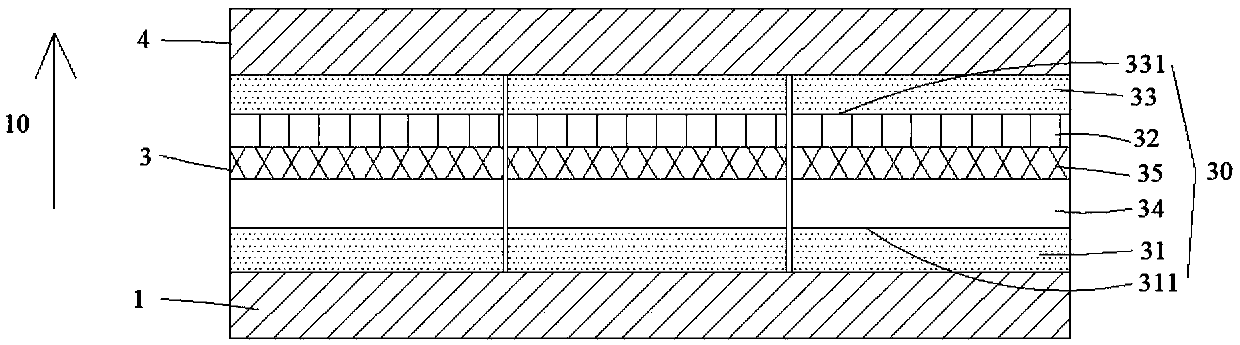

[0041] See Figure 6 The electrochromic display panel shown in this embodiment includes a first substrate 1-1, an electrochromic pixel array 1-2 and a second substrate 1-3 arranged sequentially from bottom to top, and the electrochromic pixel array layer 1- 2 includes a number of electrochromic units 1-20 arranged in an array and independently controlled. The electrochromic unit 1-20 includes a first transparent electrode 1-21, an ion storage layer 1-22, a conductive layer 1-23, electrochromic pixel layer 1-24, and second transparent electrode 1-25. Wherein, the first transparent electrode 1-21 has a first opposite surface 1-211 opposite to the second transparent electrode 1-25, and the second transparent electrode 1-25 has a second opposite surface opposite to the first transparent electrode 1-21. 1-251, in order to make the electric field distribution between the first transparent electrode 1-21 and the second transparent electrode 1-25 more uniform, this embodiment is prov...

Embodiment 2

[0044] See Figure 7 The electrochromic display panel shown in this embodiment includes a first substrate 2-1, an electrochromic pixel array 2-2 and a second substrate 2-3 arranged sequentially from bottom to top, and the electrochromic pixel array layer 2- 2 includes a number of electrochromic units 2-20 arranged in an array and independently controlled. The electrochromic unit 2-20 includes a first transparent electrode 2-21, an ion storage layer 2-22, a conductive layer 2-23, electrochromic pixel layer 2-24, and second transparent electrode 2-25. Wherein, the first transparent electrode 2-21 has a first opposite surface 2-211 opposite to the second transparent electrode 2-25, and the second transparent electrode 2-25 has a second opposite surface opposite to the first transparent electrode 2-21. 2-251, in order to make the electric field distribution between the first transparent electrode 2-21 and the second transparent electrode 2-25 more uniform, this embodiment is prov...

Embodiment 3

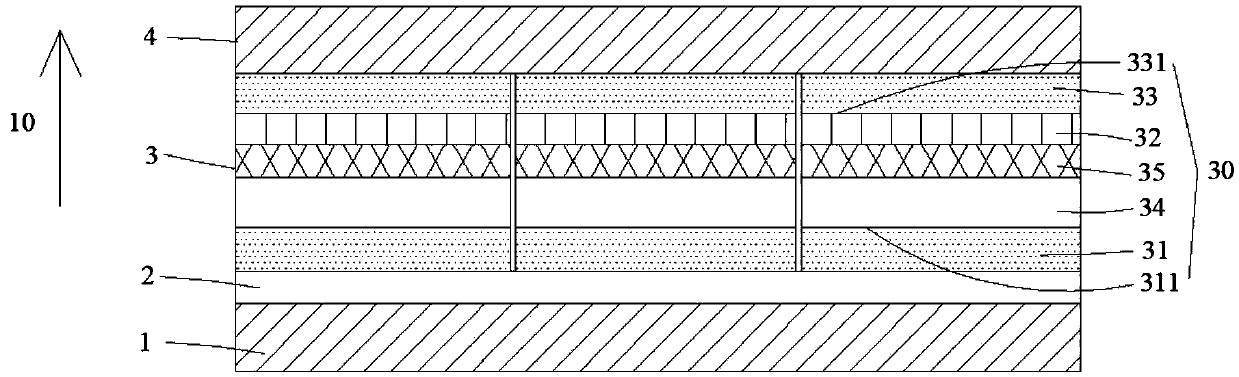

[0047] See Figure 8 , the structure of the electrochromic display panel of this embodiment is basically the same as that of Embodiment 1, and the difference is that in this embodiment, a white reflector is provided between the first substrate 3-1 and the electrochromic pixel array 3-2. Layer 3-5 and adhesive layer 3-51. In this embodiment, the white reflective layer 3-5 is composed of phenolic resin and dispersed titanium oxide, and is provided on the first substrate 3-1 by spin coating. In addition, the thickness of the white reflective layer 3-5 was 20 μm, and the thickness of the adhesive layer 3-51 was 15 μm. Compared with using a viscous white reflective layer to adhere the electrochromic pixel array 3-2, by setting the adhesive layer 3-51, a better adhesion effect can be achieved, so that the electrochromic pixel array 3-2 is more transparent. Stably fixed on the white reflective layer 3-5.

[0048] To sum up: the electrochromic display panel and electronic paper of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com