Preparation method of water-soluble essence slow-release cigarette paper

A technology for water-soluble flavor and cigarette paper, applied in the field of cigarette paper flavoring, can solve the problems of difficulty in uniform flavoring, interference with cigarettes, rough surface of finished products, etc., achieve uniform and stable aroma release, reduce smoke temperature, and fragrance retention time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of water-soluble flavor slow-release cigarette paper, comprising the steps of:

[0026] a, preparing essence emulsion;

[0027] Mix 12 parts by weight of water-soluble essence, 18 parts by weight of modified starch and 2 parts by weight of sodium alginate at room temperature, add 68 parts of water, pressurize and homogeneously stir at a homogenization speed of 5000-10000n / min, and stir for 60 —90min, stand still for 3h, make the fragrance emulsion, and the storage time of the emulsion is 1-24 hours;

[0028] b. mix

[0029] Add 99 parts by weight of the essence emulsion to 1 part by weight of pullulan and stir at a speed of 8000r / min for 20min to make the mixture evenly and obtain a flavored coating liquid;

[0030] c. The flavoring coating solution is flexo-printed on low-weight cigarette paper with a grammage of 15-25 g / m2 at a printing weight of 1-10 g / m2.

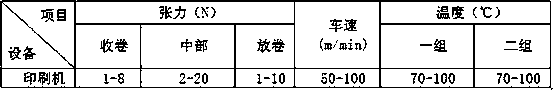

[0031] Printing parameters:

[0032]

Embodiment 2

[0034] A preparation method of water-soluble flavor slow-release cigarette paper, comprising the steps of:

[0035] a, preparing essence emulsion;

[0036] Mix 13 parts by weight of water-soluble essence, 25 parts by weight of modified starch and 2.5 parts by weight of sodium alginate at room temperature, add 59.5 parts of water, pressurize and homogeneously stir at a homogenization speed of 5000-10000n / min, and stir for 60 —90min, stand still for 3h, make the fragrance emulsion, and the storage time of the emulsion is 1-24 hours;

[0037] b. mix

[0038] 5 parts by weight of pullulan were added into the essence emulsion of 95 parts by weight and stirred at a speed of 8000r / min for 20min to make the mixing uniform, and to obtain a flavored coating liquid;

[0039] c. Gravure printing the flavoring coating solution on the low-weight cigarette paper with a grammage of 15-25 g / m2 at a printing weight of 1-10 g / m2.

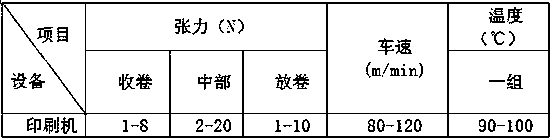

[0040] Using gravure printing, 2 sets of printing.

[0041] ...

Embodiment 3

[0044] A preparation method of water-soluble flavor slow-release cigarette paper, comprising the steps of:

[0045] a, preparing essence emulsion;

[0046]Mix 15 parts by weight of water-soluble essence, 20 parts by weight of modified starch and 2.8 parts by weight of sodium alginate at room temperature, add 62.2 parts of water, pressurize and homogeneously stir at a homogenization speed of 5000-10000n / min, and stir for 60 —90min, stand still for 3h, make the fragrance emulsion, and the storage time of the emulsion is 1-24 hours;

[0047] b. mix

[0048] 2 parts by weight of pullulan were added into the essence emulsion of 98 parts by weight and stirred at a speed of 8000r / min for 20min to make the mixture evenly, so as to obtain a flavored coating liquid;

[0049] c. Gravure printing the flavoring coating solution on the low-weight cigarette paper with a grammage of 15-25 g / m2 at a printing weight of 1-10 g / m2.

[0050] Using gravure printing, 1 set of printing.

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com