Preparation method of polyester Crepe DE chine machine fabric

A crepe chine machine and fabric technology, which is applied in the field of textile fabrics, can solve the problems of fabric crepe damage, fiber quality decline, etc., and achieve the effect of reducing damage, ensuring quality, and lasting wrinkling style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of polyester crepe chine woven fabric,

[0032] (1) The preparation process of disperse dye normal pressure dyeable polyester fiber is as follows:

[0033] The normal pressure dyeable polyester melt (intrinsic viscosity is 0.65dL / g) is extruded from the three-lobed spinneret hole on the spinneret and cooled by ring blowing; wherein, in the preparation process of the normal pressure dyeable polyester, the The mol ratio of phthalic acid, isophthalic acid and diethylene glycol is 100:3:5, and the addition of polyethylene glycol is 9wt% of the addition of terephthalic acid;

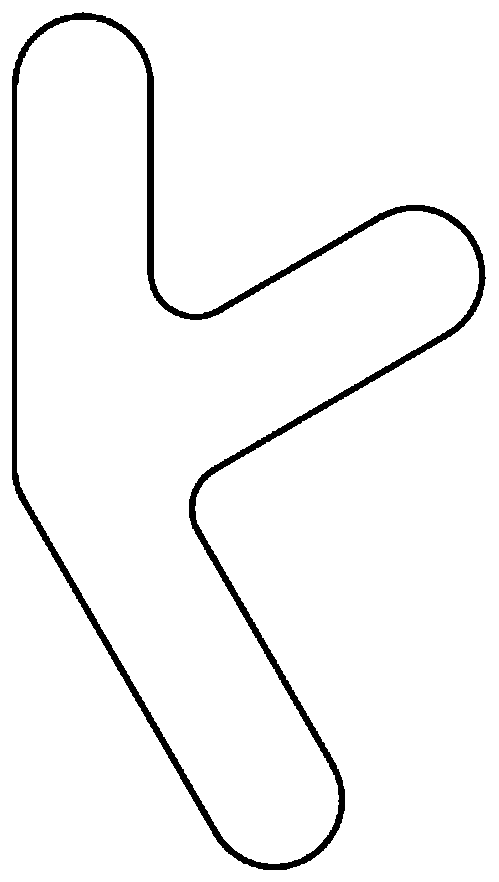

[0034] The ratio of the included angle of the center line of the three lobes of the same three-lobed spinneret hole is 1.0:1.4:1.6, the length and width of the three lobes are the same and the ratio of length to width is 3:1; different three-lobed spinneret holes The shape and size of the three lobes are the same; all the three-lobed spinneret holes are distributed in concentric c...

Embodiment 2

[0043] A preparation method of polyester crepe chine woven fabric,

[0044] (1) The preparation process of disperse dye normal pressure dyeable polyester fiber is as follows:

[0045] The normal pressure dyeable polyester melt (intrinsic viscosity is 0.66dL / g) is extruded from the three-lobed spinneret hole on the spinneret and cooled by ring blowing; wherein, during the preparation of the normal pressure dyeable polyester, the The mol ratio of phthalic acid, isophthalic acid and diethylene glycol is 100:5:6, and the addition of polyethylene glycol is 9wt% of the addition of terephthalic acid;

[0046] The ratio of the included angle of the center line of the three lobes of the same three-lobed spinneret hole is 1.0:1.5:1.7, the length and width of the three lobes are the same and the ratio of length to width is 3:1; different three-lobed spinneret holes The shape and size of the three lobes are the same; all the three-lobed spinneret holes are distributed in concentric circl...

Embodiment 3

[0055] A preparation method of polyester crepe chine woven fabric,

[0056] (1) The preparation process of disperse dye normal pressure dyeable polyester fiber is as follows:

[0057] The normal pressure dyeable polyester melt (intrinsic viscosity is 0.7dL / g) is extruded from the three-lobed spinneret hole on the spinneret and then cooled by ring blowing; wherein, during the preparation of normal pressure dyeable polyester, the The mol ratio of phthalic acid, isophthalic acid and diethylene glycol is 100:4:6, and the addition of polyethylene glycol is 10wt% of the addition of terephthalic acid;

[0058] The ratio of the included angle of the center line of the three lobes of the same three-lobed spinneret hole is 1.0:2.0:2.5, the length and width of the three lobes are the same and the ratio of length to width is 3.5:1; different three-lobed spinneret holes The shape and size of the three lobes are the same; all the three-lobed spinneret holes are distributed in concentric ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com