Reinforced perfluorocarboxylic acid ion exchange membrane with bubble thinning function and preparation method thereof

A perfluorocarboxylic acid ion and perfluorocarboxylic acid technology, applied in the field of ion exchange membranes, can solve the problems of ineffective reduction of cell voltage, foaming and peeling of the composite membrane layer, and large difference in ion migration number, etc., to improve electrolysis Current efficiency, improved anti-foaming performance, simple and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

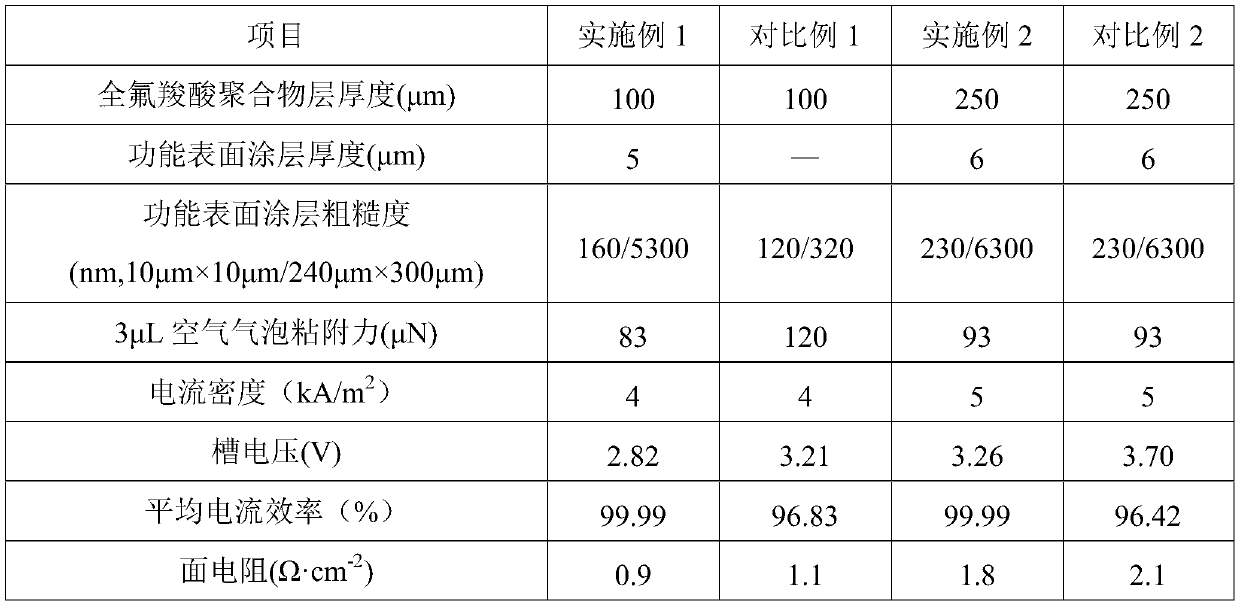

Embodiment 1

[0042] Prepare the enhanced perfluorocarboxylic acid ion exchange membrane with air bubble function as follows:

[0043] (1) The perfluorocarboxylic acid resin of IEC=0.8mmol / g is extruded and casted to obtain a perfluorocarboxylic acid ion exchange resin base film with a thickness of 100 μm, and then the polytetrafluoroethylene fiber and silk are according to the volume ratio of 1: 1 Composite braided porous reinforcement (thickness 50 μm, porosity 30%), soaked in ultrasonically treated trifluorotrichloroethane solvent for 1.5 h, taken out and dried, and mixed with perfluorocarboxylic acid ion exchange resin base The membrane is compounded to form a perfluorocarboxylic acid ion exchange membrane precursor;

[0044] (2) Under 180°C and 120t pressure, the perfluorocarboxylic acid ion exchange membrane precursor is subjected to overpressure treatment with an overpressure machine at a speed of 45m / min. After the overpressure treatment, it is then immersed in an alkaline solution ...

Embodiment 2

[0061] Prepare the enhanced perfluorocarboxylic acid ion exchange membrane with air bubble function as follows:

[0062] (1) The perfluorocarboxylic acid resin of IEC=1.2mmol / g is extruded and casted to obtain a perfluorocarboxylic acid ion exchange resin base film with a thickness of 250 μm, and then the polytetrafluoroethylene fiber and silk are according to the volume ratio of 1: 2 Composite braided porous reinforcement (thickness 100μm, porosity 20%), soaked in ultrasonically treated trifluorotrichloroethane solvent for 1.5h, taken out and dried, and mixed with perfluorocarboxylic acid ion exchange resin matrix The membrane is compounded to form a perfluorocarboxylic acid ion exchange membrane precursor;

[0063] (2) Under the pressure of 160°C and 100t, the perfluorocarboxylic acid ion exchange membrane precursor is subjected to overpressure treatment with an overpressure machine at a speed of 45m / min. After the overpressure treatment, it is then immersed in an alkaline s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com